Why the HM Series End Mills Are the Ultimate Choice for High-Hardness Materials

Table of Contents

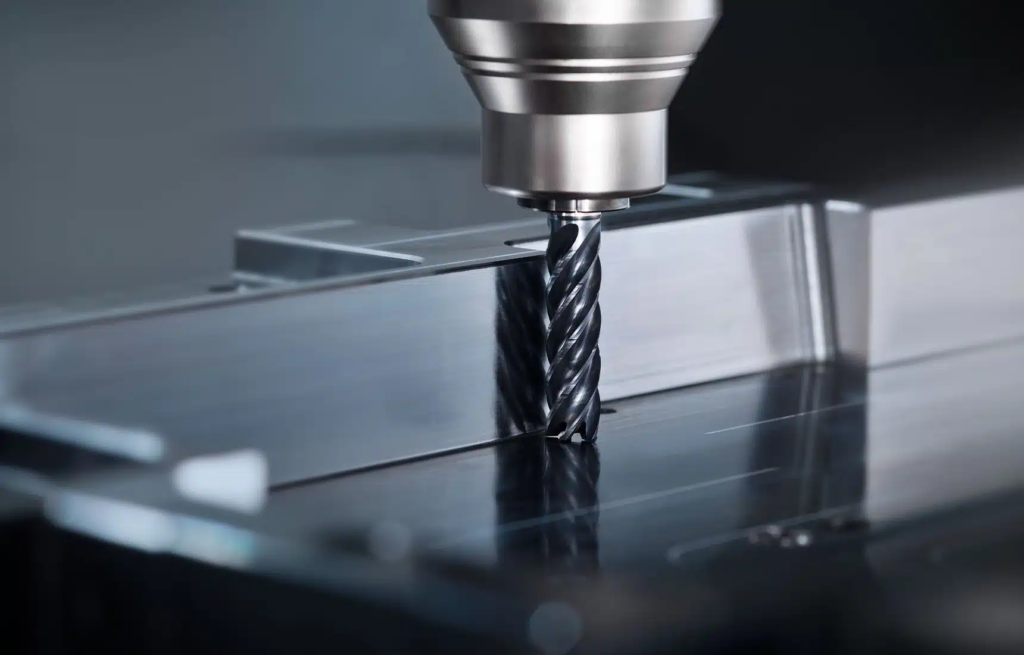

Machining high-hardness materials pushes both the tool and the operator to their limits. Steels in the 65-70 HRC range can very quickly blunt even premium-grade tooling if not approached in the correct manner, generate excessive amounts of heat, and break down surface quality. All of those risks translate directly into higher costs, more downtime, and missed delivery schedules when an industry requires dimensional precision and finish integrity as non-negotiable.

The HM Series End Mills by HNCarbide were designed as a solution to such problems through construction based on strength, support, and predictable extreme condition capabilities. Backed up by advanced substrate material, coating, and geometry techniques, these tools outperform conventional carbide tools in places where the latter fall short.

This makes them a good choice for aerospace, die and mould applications or any other industry that needs consistent machining in hardened steel.

Understanding the Needs of High-Hardness Machining

Cutting hardened steel and other extra-hard materials requires much more than normal cutting ratings. At this stage of hardness, which can get up to 70HRC, extreme stress is imposed on the cutting edge with every pass; thus, any weakness in either the tool design or material used is exposed very quickly.

Three core challenges dominate in this space:

- Tool wear: Hardened steelhas an abrasive nature that increases the rate of edge degradation, lowering the amount of time it takes for precision to diminish and replacement costs to increase.

- Heat generation: High cutting forces generate significant heat, which may lead to softening of the tool material or destruction of coatings if not adequately controlled.

- Surface finish quality: As wear increases, achieving the required Ra values becomes harder, risking rework or rejected parts.

These issues are most prevalent in sectors where part complexity and material properties demand exceptional tooling. Aerospace components often involve heat-resistant alloys with high hardness ratings.

Die and mould applications require flawless cavity finishes in hardened tool steels. Medical tooling demands ultra-fine tolerances in stainless and titanium-based alloys.

In any case, the success of high hardness machining shall depend on the right matching of process parameters with tooling designed to be resilient and stable, as well as provide consistent performance under pressure.

Major Features of the HM Series End Mills

The HM Series from HNCarbide solves those very pain points that manufacturers experience when machining hardened steels and any other ultra-hard materials. Every aspect of their construction, from the carbide grade to the flute geometry, is made to resist high cutting forces and manage heat by delivering a consistent surface finish over extended production runs.

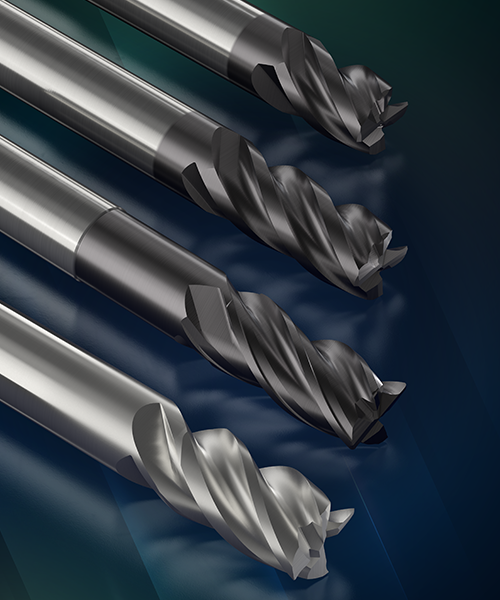

Made from Ultra-Fine Carbide Substrates

The HM Series is made from ultra-fine grain carbide, a substrate material designed to provide ultimate hardness with great fracture resistance. It allows cutting edges to stay keen and strong for a long time, even under operation on hardened steels above 60 HRC.

Such strength is indeed required while running tools like a 4 flute end mill that shall be used for fine finishing, or maybe a bigger 1 1 4 end mill which will be removing heavy stock in die and mould applications.

The higher transverse rupture strength (TRS) of the material ensures great resistance to chipping in aggressive passes, making these tools equally suitable for uninterrupted high-speed cutting as well as interrupted operations.

In precision work, such as using a 1 16 end mill for fine detail, the same carbide composition assures predictability and dimension retention. By holding its edge longer during extended runs and providing consistent results across both delicate and heavy-duty applications, the HM Series delivers the possibility of achieving productivity at a lower tooling cost with better part quality.

Excellent Quality Coatings

Machining hardened steels in the 60–70 HRC range generates extreme thermal and mechanical stress, with cutting zones often exceeding 800 °C. Without the right coating, these conditions quickly degrade cutting performance, causing rapid edge wear, micro-chipping, and reduced dimensional accuracy.

The HM Series addresses this challenge with advanced Aluminium Titanium Nitride (AlTiN) coatings applied through a precision Physical Vapour Deposition process. During machining, AlTiN forms a stable aluminium oxide layer that acts as a thermal shield, directing heat into the chip instead of the tool substrate. This thermal barrier significantly reduces the risk of softening and maintains structural integrity under continuous high-load conditions.

In practice, the coating not just improves oxidation resistance but also minimises friction between the tool and the workpiece, allowing chips to evacuate smoothly and cutting forces to remain stable. The result is longer tool life, consistent wear patterns, and a surface finish that can be relied on, even during prolonged dry or semi-dry cutting cycles.

This level of coating performance is very close to the requirements of German manufacturing environments, where precision, process reliability, and extended tool service life are critical to meeting production targets.

Specialised Flute Design

The flute geometry of the HM Series has been designed thoroughly with high-hardness machining in mind. Consequently, vibration control and chip evacuation have a direct impact on tool life and part quality. The usage of variable helix angles and asymmetric flute spacing together breaks down the chatter of the harmonic. As a result, the cutter can work smoothly at high feed rates even in hardened steel above 60 HRC.

Polished and deep flute profiles together with optimised rake angles greatly improve chip flow, and as a result, heat is taken off from the cutting zone and is not absorbed by the cutting edge. This is quite an important point when milling materials such as die steel, tool steel, and hardened alloys, as extreme heat can be the cause of rapid edge degradation.

This design is a source of the following benefits:

- Consistent surface finishes within tight tolerance ranges

- Reduced spindle load and energy consumption during extended runs

- More predictable wear patterns, aiding in tool life planning

The result is not just a smoother cutting action but also higher process stability, which makes the HM Series a reliable option for continuous, high-precision production in demanding German CNC environments.

Performance Data

Working on a steel that had been hardened to 65-70 HRC using a cutting tool is a real challenge. Only the most resistant cutters can be tested under such conditions. The HM Series responded with the tool life extension and surface finish maintenance that far exceeded those achieved with traditional carbide end mills.

Several tests comparing the lifetime of the tool and the quality of the surface have shown the capability of the HM Series against the fatigue of heavy usage. The results allow for a claim up to 2.5 times tool life improvement in various hard-type steel performance scenarios.

Metric | Conventional Carbide End Mill | HN Series End Mill |

Tool Life | 10 minutes | Up to 25 minutes |

Surface Roughness (Ra after run) | ~1.2 µm | ~0.6 µm |

Edge Sharpness Retention | Noticeable degradation | Minimal edge wear |

Tool Tracking | No marking | Laser-marked shanks |

Practical Applications

Machining high-hardness materials is not limited to a single industry. It spans sectors where precision, durability, and repeatability are essential. The HM Series End Mills are engineered to deliver consistent results in these demanding environments, where conventional cutters often fail prematurely.

Mould and Die Manufacturing

Mould and die production are processes that usually require the use of hardened steel with a value of about 60–70 HRC, and in such cases, the standard cutters struggle to wear out rapidly and degrade their surfaces. On the other hand, the HM Series End Mills are the leaders in such a situation, providing the prolonged tool life and at the same time maintaining the high accuracy for the detailed geometries.

The meticulously fabricated carbide base ensures the highest hardness without being brittle, while layers of AlTiN stand as a heat barrier against the fire that comes from the area of continuous cutting. This allows the tools to get the surface of the cavity better and the edges sharper, thus eliminating their need for extra cleaning and polishing.

In the tool and die industry of Germany, which is very competitive, and where precision and delivery time are crucial, these machines not only provide better results but also allow those qualities to be maintained over multiple productions of the same part.

Precision Components in Aerospace and Defence

Aerospace and defence applications require the highest possible consistency levels. The components are obliged to pass the stipulations of safety and performance criteria to the last detail. The sector uses materials such as titanium alloys, Inconel, and hardened steel quite often, and these present such problems as heat buildup, rapid tool wear, and dimensional instability during the cutting process.

The HM Series End Mills are perfect for these situations with their highly advanced coatings and perfectly constructed flute geometry, which guarantees the stability of the process even under very harsh conditions.

Common performance advantages in aerospace and defence are:

- Thermal stability that permits cutting continuity in heat-resistant alloys.

- Edge retentionto support precise profiles for long runs.

- Vibration reductionto achieve the tolerances and surface finishes possible.

The HM Series enables suppliers to provide accurate information for multipart aerospace components, such as turbine blades, structural fittings, and engine housings. End mills can be utilized for the equivalent reason for solidifying shielded plates, weapon framework parts, and accuracy direction lodgings.

Hard Turning Alternatives in Specific Setups

In some production scenarios, advanced milling solutions can replace or complement hard turning when machining high-hardness materials above 60 HRC. The HM Series End Mills perform exceptionally well in setups where traditional hard turning would be challenging or inefficient, especially when complex geometries or tighter tolerances are required.

These setups typically include:

- 5-axis CNC milling machines handling intricate contours and multi-surface parts in hardened tool steels.

- Bridge-type machining centres working on large, heavy moulds or dies where rotating the workpiece for turning would be impractical.

- Vertical machining centres (VMCs) configured with high-speed spindles and rigid fixturing for small-to-medium hardened components.

- Hybrid mill-turn machines where certain features are better achieved through milling passes rather than turning operations.

Advantages of using the HM Series in these setups include:

- Reduced cycle times by eliminating secondary grinding or polishing steps.

- Improved surface integrity with consistent finishes even in 65–70 HRC steels.

- Cost efficiency due to extended tool life and reduced changeovers.

German manufacturers in mould repair, aerospace fixtures, and precision hardened components often adopt this approach to maximise flexibility while maintaining production quality.

Customer Support and Added Value

Choosing a hardened steel cutter is only part of it. Constant supply, technical support, and logistics are just as important. HNCarbide makes sure customers get not just top tools but also easy buying that fits global manufacturing needs.

Dedicated export knowledge support guides buyers through elaborate customs so that shipments are compliant with all the documentation and import standards. This reduces delays in shipment and consequently in the production schedule. We have easy payment processes as well as special shipping channels that are optimised for timely, safe delivery across Europe and its industrial hubs.

Also, we let makers check our HM Series End Mills with easy test samples, so groups can see how the tool works before making big buys. This try-first plan grows trust while cutting buy risk.

For companies in precision machining, aerospace, and mould production, these added-value services mean more than convenience. It ensures reliable supply chains, predictable costs, and assured quality compliance. Thus enabled by the infusion of technical excellence with its operational support offering, HNCarbide is positioned as a trusted long-term partner for high-hardness machining solutions.

Conclusion

Ultra-fine carbide substrates, state-of-the-art coatings, and flute designs of the HM Series End Mills bring about excellent results when milling applications of high hardness. Their performance validated in materials up to 70 HRC, long tool life, and the surface finish above ordinary, makes it an easy choice for the many German and European producers who need steady, provable quality.

HNCarbide’s technical consultation, export-ready logistics, and availability of testing samples ensure that every purchase is backed by expertise and trust.

Request your technical consultation, receive free test samples, and explore our detailed HM Series catalogue to see how these cutters can optimise your hardened steel machining processes.