Why Do End Mill End Teeth Matter So Much?

Table of Contents

When selecting a solid carbide end mill, most engineers instinctively focus on flute count, helix angle, or coating.

But one critical area is often underestimated:

👉 the end teeth geometry of the end mill.

Why can one end mill plunge smoothly into solid material while another burns, chatters, or breaks at the tool center?

Why do two tools with the same diameter and coating behave completely differently during slot entry or pocket machining?

The answer almost always lies in end teeth design.

This article takes a deep, engineering-focused look at:

- End teeth geometry of solid carbide end mills

- Center-cutting vs non-center-cutting designs

- Rake angles, relief angles, dish angle, and gash structures

- How these features directly affect plunging, slotting, tool life, and surface quality

If you machine aluminum, steel, stainless steel, or hardened alloys, this guide will help you understand what actually matters—and why.

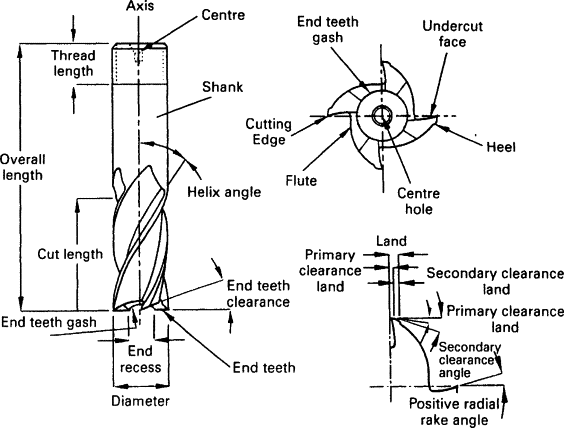

What Are End Teeth on an End Mill, Exactly?

The end teeth are the cutting edges located on the end face of an end mill, oriented perpendicular to the tool axis.

Unlike peripheral (flute) cutting edges, end teeth are responsible for:

- Axial plunging

- Entry into slots or pockets

- Bottom surface formation in cavities

In real machining, end teeth are often subjected to:

- Poor chip evacuation

- High compressive forces

- Intermittent engagement

This makes their geometry far more sensitive than side flutes.

Why Can Some End Mills Plunge While Others Cannot?

What Is Center-Cutting, Really?

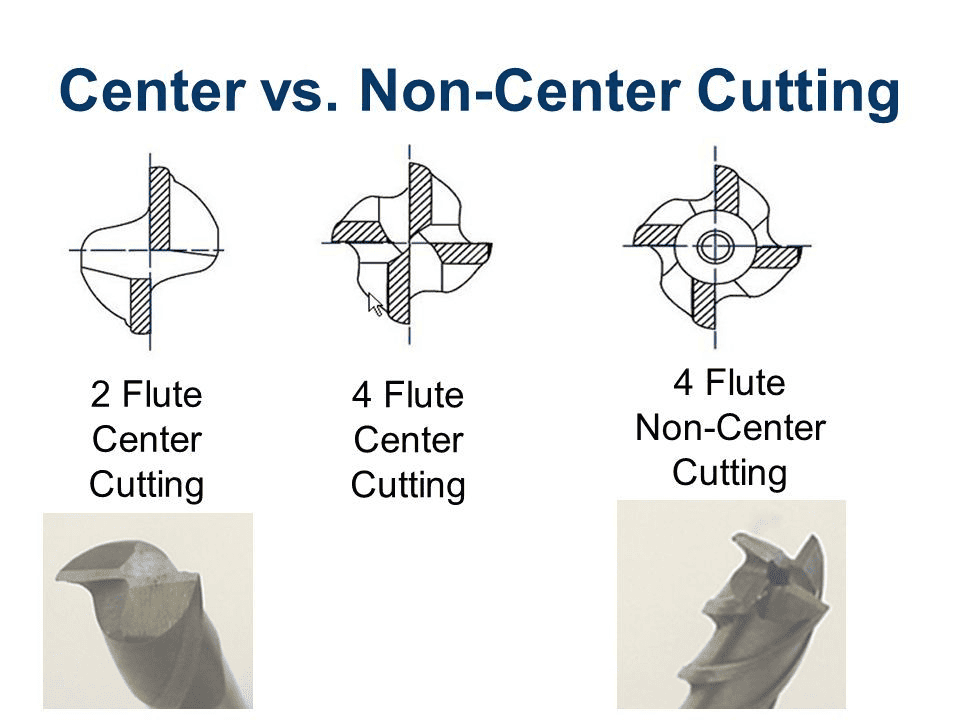

End mills are commonly divided into two categories:

Design Type | End Teeth Reach Tool Center? | Can Plunge Axially? |

Center-cutting end mill | Yes | Yes |

Non-center-cutting end mill | No | No |

But this definition is too simplistic.

What Actually Makes an End Mill Center-Cutting?

A true center-cutting end mill requires two simultaneous conditions:

1.Over-center end teeth

2.End cutting edges extend beyond the tool axis

3.Proper end gash geometry

4.A gash removes material near the center to create clearance and chip space

Without both, plunging performance will be unstable—even if the catalog says “center-cutting.”

Over-Center vs Non-Over-Center End Teeth: What’s the Real Difference?

Feature | Over-Center | Non-Over-Center |

Axial plunging | Excellent | Impossible |

Bottom surface quality | Good | Poor / incomplete |

Chip evacuation | More complex | Simpler |

Tool rigidity | Slightly lower | Slightly higher |

Modern CNC machining strongly favors over-center designs, especially in automated, multi-axis operations.

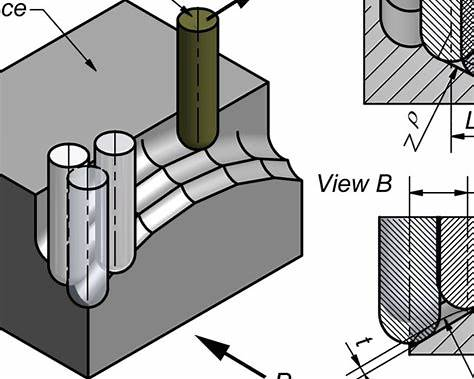

How Do End Teeth Actually Cut During Plunging?

To understand end teeth geometry, we must analyze cutting mechanics, not just shapes.

When plunging axially:

- The cutting speed vector is tangential to tool rotation

- Each end tooth engages intermittently

- Chip thickness increases rapidly near the outer radius

This creates a unique cutting plane, different from side milling.

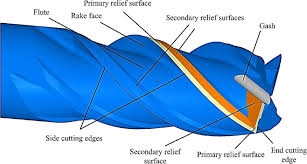

Rake Angle and Relief Angle of End Teeth: Same Terms, Different Physics

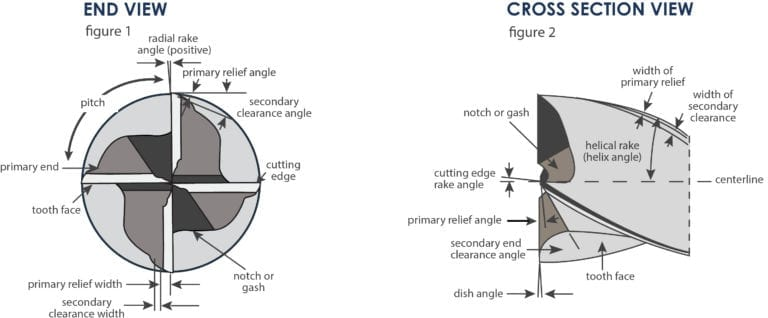

Like all cutting tools, end teeth have:

- Rake angle(chip flow direction)

- Relief angle(clearance behind the cutting edge)

But due to axial engagement:

- These angles are defined on local cutting planes

- They vary along the radius of the end tooth

Why Is This Important?

Because poor rake design at the tool center leads to:

- Chip compression instead of shearing

- Heat accumulation

- Built-up edge (BUE), especially in aluminum

Why Do High-Performance End Mills Use a Secondary Relief Angle?

End teeth operate in a confined chip space.

To prevent:

- Chip packing

- Edge rubbing

- Thermal overload

Modern solid carbide end mills introduce a secondary relief angle behind the primary relief.

Relief Type | Function |

Primary relief | Forms the cutting edge |

Secondary relief | Reduces friction, improves chip evacuation |

This is especially critical for:

- Small-diameter end mills

- Deep cavity machining

- Stainless steel and titanium alloys

What Is the Dish Angle (End Relief Angle) — and Why Is It Almost Always ~2°?

The dish angle, also called end relief angle, is the slight concave shape of the end face.

Typical values:

- 1.5° – 2.5°for most solid carbide end mills

Why Not Flat?

A perfectly flat end face would:

- Rub against the workpiece bottom

- Cause excessive heat

- Destroy surface finish

Why Not Too Large?

An excessive dish angle would:

- Reduce edge strength

- Increase center chipping risk

- Compromise tool life

Dish Angle | Effect |

< 1° | High friction, poor finish |

1.5–2.5° | Optimal balance |

> 3° | Weak edge, unstable cutting |

This “dish” shape also explains why it’s often called the dish angle in manufacturing practice.

Axial Cutting vs Radial Cutting: Why Does the Same Angle Behave Differently?

When machining:

- Axial feed→ end teeth are the main cutting edges

- Radial feed→ peripheral flutes become primary

In radial milling:

- End teeth act as secondary cutting edges

- Dish angle effectively becomes a secondary clearance angle

This dual role makes end teeth geometry one of the most complex areas of end mill design.

What Is an End Gash — and Why Is It Critical for True Center Cutting?

An end gash is a localized material removal at the end face.

Its purposes:

- Open chip space near the center

- Allow over-center cutting edges to function

- Prevent chip congestion during plunging

Poor Gash Design Leads To:

- Center burning

- Excessive thrust force

- Tool breakage at small diameters

High-end manufacturers often customize gash geometry per product series, especially for:

- Aluminum-specific end mills

- High-feed end mills

- Micro end mills (< Ø3 mm)

Real-World Product Design: How End Teeth Differ by Application

Application | Typical End Teeth Design |

Aluminum machining | Sharp rake, deep gash, large chip space |

Stainless steel | Moderate rake, reinforced center |

Hardened steel | Strong edge, smaller dish angle |

High-speed slotting | Optimized gash + polished end face |

This is why one “universal” end mill rarely performs optimally across all materials.

What Should You Check Before Choosing an End Mill for Plunging?

Ask these questions:

1.Is it truly center-cutting, or only nominally?

2.Does the end gash provide sufficient chip space?

3.Is the dish angle appropriate for my material?

4.Are the end teeth reinforced or sharp?

These details matter more than coating alone when plunging or slotting.

Final Thoughts: End Teeth Are Small — But Decide Everything

End teeth occupy only a few millimeters of an end mill, yet they determine:

- Whether axial entry is stable

- Whether chips evacuate or pack

- Whether the tool lasts minutes or hours

A well-designed solid carbide end mill always starts from end teeth geometry, not just flute design.

If you want consistent results in modern CNC machining, don’t just ask “how many flutes?”

Ask instead:

👉 How are the end teeth designed, and for what exact cutting conditions?