Why DIN Standard End Mills Are the Benchmark for European CNC Machining

Table of Contents

In Europe’s world of precision machining, DIN standard end mills are trusted daily. They are used in German factories and shops across the board. That is because devices are accurate, consistent, and simple to work with.

There is high demand and elsewhere for cutting equipment to tight tolerances. Aerospace, automotive, and mold & die industries require parts to fit perfectly. They will not accept guesswork. These do a good job of filling this requirement. They play by the rules of size, shape, and quality. That makes it simple to obtain the same outcome every time.

With devices, there are fewer installation issues. The devices are a good fit with CNC machines. Spindle interfaces, holders & machine calibration are all in spec. This reduces errors and boosts uptime on the shop floor. At a glance, it provides you with consistency, accuracy, and a fluid motion gear. That makes them the preferred choice for high level CNC work in Germany and throughout Europe.

Growing Demand for High Precision Cutting Tools in Europe

The manufacturing industry is evolving rapidly. Factories produce more components with tighter tolerances. Businesses, particularly in the automotive and aerospace industries, require tools that cut accurate shapes every time.

More manufacturers make use of automation and CNC equipment. This equipment operates long and quickly. They require extremely precise cutting to maintain parts flawless and operating. That creates demand for high precision ball end mills with strict specifications.

The tools also need to cut tough materials. Think titanium, hardened steels, or new light alloys. These materials last longer and weigh less. But they are hard to shape. So cutting devices must be tough, too. Coatings, such as those with TiAlN, help here. They resist heat and wear. This helps shops keep cutting on tight schedules.

Europe also cares about green choices. The EU pushes for lower waste and safer work. Tool designers respond with coatings and designs that last longer and cut cleanly. This supports a green yet precise factory floor.

Germany is a centre for advanced manufacturing. Companies there push standards higher and expect equipment that matches. That makes standard end mills essential. They fit setups, yield reliable precision, and meet industry expectations without fuss. At a high level, demand for cutting is rising because manufacturing must be faster, more exact, and more reliable.

Why DIN Standards Remain the Gold Benchmark

It stands for the Institute for Standardization – called Deutsches Institut für Normung. It sets the rules for machines and parts. These rules cover size, shape, fit, and performance. They make sure every device works the same everywhere.

Factories, especially, need tools they can trust to be precise and consistent. Its rules help firms do just that. They know they’ll get the same fit carbide end mill with perfect accuracy, no matter the supplier. This consistency cuts setup time and avoids mistakes.

It also makes it easy to mix and match with machines. Machine makers design spindles, holders, and interfaces to follow specs. That means best fit, less error, and smoother work. Makers like Gühring, MAPAL, and Hoffmann follow closely. They build with tight control over material, size, and coating. Aerospace, automotive, and medical firms rely on them. They must cut tough materials with exact shapes and have a long life.

In the busy EU market, its tools cut inventory headaches. Shops stock items they use every day without worrying about fit or tolerances. That makes logistics and ordering cleaner. And no surprises on the shop floor.

What Sets DIN End Mills Apart

Carbide end mill 1 2 stand out because they follow strict rules for size, quality, and design. These rules make sure every tool performs the same, no matter where it’s made or who makes it. For industries that depend on exact cuts and smooth finishes, this level of control matters.

1. Tighter Dimensional Control

These are made with very small size tolerances. Even a few microns of difference can affect the cut. These fit firmly into the spindle, giving stable, vibration free cutting. This leads to higher accuracy on every job.

2. Better Surface Finish

The cutting edges on standard end mills are ground to high quality. This implies that they produce smooth surfaces directly from the machine. Most can get Ra values below 1.6 µm, which is best for molds, dies, and accuracy components.

3. Perfect Fit for European CNC Machines

The majority are designed with DIN holder sizes. Shank types such as 1835 A & 1835 B have exact machine spindle matching. This avoids fitting problems and conserves setup time.

4. Specialized Tool Types for Different Jobs

It addresses a broad variety of shapes. Roughing end mills according to DIN 6581 deal with heavy cuts. Flat end types such as DIN 844 provide neat edges and ball nose mills under 845 create smooth curves.

5. Backed by Trusted Brands

Manufacturers like Gühring, MAPAL & Hartner produce strictly. Their quality standards guarantee long life and reliable results in extreme industries like aerospace, automotive and medical.

These are not only cutting tools, they are part of an entire system designed for accuracy. They make shops work faster, minimize mistakes & preserve quality on every production run. That is why they continue to be the best choice for serious makers.

Applications Across Key Industries

4 flute end mill plays a key role in industries that need pinpoint accuracy and strong performance:

- Aerospace: These mills machine hard and light materials such as titanium, superalloys, and aluminum. They machine the turbine blades, landing gear components, and aircraft structures with accuracy and smooth surface finishes.

- Automotive: In this industry, DIN end mills manufacture engine blocks, transmission components & delicate assemblies. They maintain close tolerances and deliver clean finishes, which are required for secure and reliable automobiles.

- Mold & Die: Toolmakers use these mills to create hardened steel or aluminum molds and dies. They produce sharp cavities and precise shapes, which make them the standard in injection molding and casting.

- Medical Devices: These must be clean, precise & extremely reliable. DIN end mills are used to machine surgical, small implants, and diagnostic components from biocompatible metals like titanium.

- Energy & Electronics: These mills tackle parts for wind turbines, pumps, and hydraulic systems. They also shape copper and aluminum components for electronics, like heat sinks and housings, where fine detail and reliability are crucial.

End mills are made to meet in applications where repeatability and precision are not a choice. Shaping aircraft components, molding, or designing medical implants, they provide results on which European producers trust.

Metric | Typical Range | Why It Matters |

Dimensional Tolerance | Diameter: 0 / -0.006 mm (≤ 3 mm) | Ensures a tight fit in holders. No wobble, better repeatability. |

Surface Roughness RA | 0.2 µm – very fine finish | Smooth surfaces reduce wear and improve seals. |

Tolerance Classes – DIN ISO 2768, fine | ±0.05 mm for lengths 0.5–3 mm | Tight control over tool geometry and consistency. |

DIN end mills are made to close tolerances in both dimensions and surface finish. The small dimensional variation reduces product setup errors and extends tool life. And the excellent surface finish makes parts fit closer, run more smoothly & have longer life.

Performance Factors

It begins with selecting the proper carbide grade and coating. Solid materials are tungsten, titanium, or tantalum. These materials improve the management of heat and wear resistance over HSS.

End mill coatings bring another layer of strength.

- TiN helps cut smoother and run 20 – 30 percent faster.

- TiCN is harder and wears well in steel cutting.

- TiAlN and AlCrN resist heat really well and extend life.

Edge Design & Chip Flow

Chip flow is vital. Tools with a strong secondary rake face help chips exit better. One study showed that such a design cuts 38 percent less force and lowers heat by up to 61 percent.

- 2 flutes are best for soft materials like aluminum, as they clear chips well.

- 4+ flutes add strength and a smooth finish for tough metals.

- Corner Radius: A slight curve at the edge improves strength and helps cut deep slots without chipping.

Feeds & Speeds

Correct means less wear, better finishes, and longer life. Use formulas:

- RPM = Cutting Speed × 3.82 ÷ Tool Diameter

- Feed Rate = RPM × Feed per Tooth × Flute Count

They emphasize that coating types require corresponding speeds and feeds. Suppliers often quote exact values to begin with. When you combine the proper carbide grade and coating with smart edge design and proper cutting conditions, you achieve more durable tools and improved cutting. That means fewer breaks, improved surface finish, and more shop uptime.

Case Example

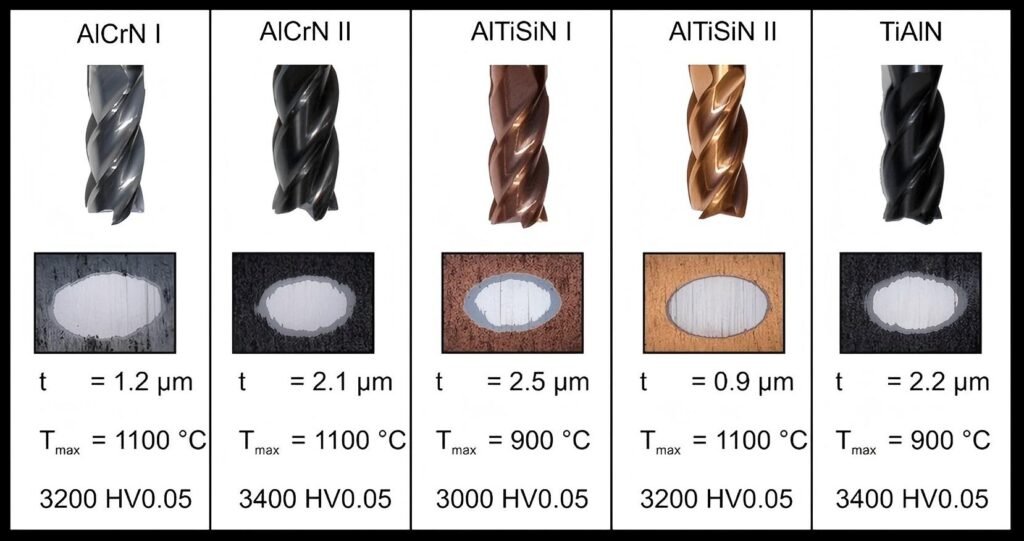

The image above is of a DIN standard end mill test result. It’s not a marketing picture – it’s evidence of how these tools cut in real-world CNC work. The photo shows the smooth, even cutting edges and the accurate geometry from strict DIN manufacturing standards.

In this trial, the tool was tested on a typical 5 axis CNC milling machine in automotive part production. The workpiece material was 58 HRC hardened steel, one of the most challenging tasks for a cutting tool. However, the DIN end mill provided a surface roughness of Ra 1.2 µm in the first pass. When a high-performance TiAlN coating was used, the roughness became even better, revealing a smooth, clean surface on the entire part.

Why does this make a difference? For industries such as aerospace, automotive, and mold making, having a low Ra value results in fewer secondary finishing operations, less polishing, and quicker turnaround. It is time & cost-saving without sacrificing part quality.

To make testing convenient, HNCarbide provides a free sample for under $10 for approved buyers. This enables workshops at large to test these end mills on their own equipment, with their own cutting parameters. It’s an easy way of testing accuracy, surface finish, and overall reliability prior to ordering larger quantities. Several buyers use these results to verify that DIN standard end mills fulfill their precise requirements.

This real-world data and sample program show that they are trusted in demanding manufacturing. They provide measurable precision, consistent quality, and proven performance, supported by results you can see.

Conclusion

DIN end mills bring together three things that matter most in machining. They follow strict German standards, so each tool performs the same way, batch after batch. This makes them a safe choice for CNC shops that can’t afford errors or downtime. The accurate dimensions help create clean cuts, while the strong build means longer tool life and less waste. For buyers, this is more than just a cutting tool, it’s a solution that supports smooth production and better results. Whether you work in automotive, aerospace, mold making, or precision engineering, DIN end mills can meet high demands without compromise.

If you want to know more, request data sheets, or discuss the right coatings and sizes for your jobs, our team is ready to help. We also provide technical advice to make sure you get the most out of your tools. You can even request a sample to test in your own setup before making a large purchase. Your machining goals are important, and we’re here to make sure your tools help you reach them.