Thread Milling Explained: Why Are Thread Mills Replacing Taps in Modern CNC Machining?

Table of Contents

Threaded holes are everywhere in precision manufacturing—but why is thread milling increasingly replacing traditional tapping in modern CNC machining?

From hardened steel molds to titanium aerospace parts, thread mills have become the preferred solution for engineers who demand higher precision, lower risk, and greater flexibility.

This article provides a practical, engineering-focused guide to thread milling, covering working principles, tool types, applications, and real CNC considerations.

What Is a Thread Mill and Why Is It Different from a Tap?

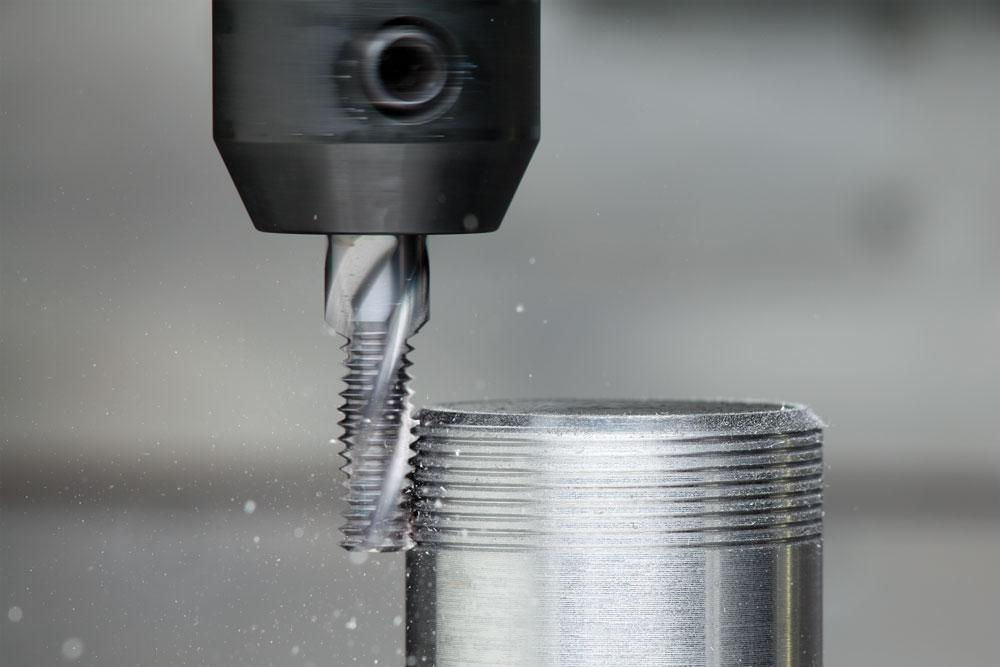

A thread mill is a rotary cutting tool used on CNC machining centers to generate internal or external threads by helical interpolation, rather than axial forming.

Unlike a tap, which cuts or forms the entire thread profile in one axial motion, a thread mill moves in a controlled circular path while the Z-axis advances by one pitch per revolution.

Why does this matter?

Because only a portion of the cutting edge is engaged at any time, thread milling:

- Reduces cutting forces

- Improves chip evacuation

- Allows precise diameter and tolerance control through tool compensation

How Does Thread Milling Work in CNC Machining?

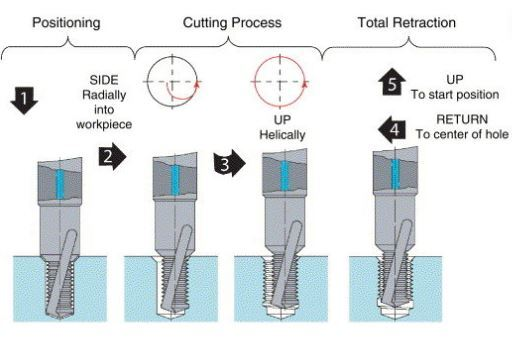

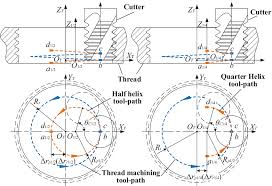

Thread milling requires 3-axis synchronization:

- X–Y axesperform circular interpolation (G02 / G03)

- Z-axismoves linearly by one thread pitch per revolution

This creates a helical cutting motion that gradually forms the thread profile.

CNC requirements for thread milling:

- Rigid machining center

- Accurate interpolation capability

- Stable spindle performance

- CAM or CNC support for thread milling cycles

Modern CNC machines and CAM systems make thread milling both reliable and repeatable in production environments.

Thread Mill vs Tap: Which One Makes More Sense Today?

Is thread milling really better than tapping?

In many modern machining scenarios—yes. Especially where precision, safety, and material difficulty are critical.

Thread Milling vs Tapping (Process Comparison)

Aspect | Thread Milling | Tapping |

Cutting method | Helical interpolation | Axial cutting / forming |

Cutting force | Low, distributed | High, concentrated |

Tool breakage risk | Very low | High, often catastrophic |

Diameter adjustment | Via tool compensation | Not adjustable |

Blind hole capability | Excellent | Limited |

Hardened materials | Up to HRC 60–68 | Poor or impossible |

Chip evacuation | Short, broken chips | Long spiral chips |

For high-value or difficult-to-machine parts, thread milling significantly reduces scrap risk and rework.

Solid Carbide Thread Mills: The Precision Standard

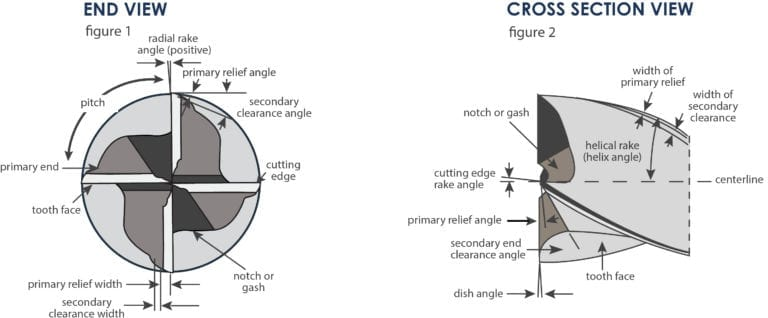

Solid carbide thread mills are the most widely used tools for precision CNC threading.

Why solid carbide?

- High rigidity and wear resistance

- Excellent vibration damping

- Suitable for hardened steel, stainless steel, titanium, and superalloys

- Ideal for tight tolerances and small thread sizes

Typical applications:

- Mold and die components

- Aerospace structural parts

- Medical and precision mechanical components

Typical Solid Carbide Thread Mill Capabilities

Parameter | Typical Range |

Thread size | M1 – M20 / UNC–UNF equivalents |

Material hardness | Up to HRC 68 |

Thread forms | Metric, UNC, UNF, NPT, BSP |

Pass strategy | Single-pass or multi-pass |

Tolerance control | CNC tool compensation |

Indexable Thread Mills: Cost Efficiency for Large Threads

For larger thread diameters or high-volume production, indexable thread mills provide a cost-effective solution.

Instead of replacing the entire tool, only the thread mill inserts are changed, reducing tooling cost per part.

Advantages:

- Lower cost per thread

- Suitable for large-diameter threads

- Consistent profile through insert geometry

Limitations:

- Less suitable for very small threads

- Requires rigid toolholding and stable machines

Single-Point vs Multi-Form Thread Mills: Which Should You Choose?

Single-point (single form) thread mills:

- One cutting tooth

- Maximum flexibility

- Ideal for prototypes and variable thread sizes

Multi-form thread mills:

- Full thread profile on the tool

- Faster cycle times

- Best for standardized, high-volume production

Which Thread Forms Can Be Machined by Thread Milling?

One major advantage of thread milling is its versatility in thread forms.

Common thread forms:

- Metric thread mill (ISO)

- UNC / UNF thread mill

- NPT and BSP thread mill

- ACME and trapezoidal thread mill

- Buttress thread mill

- UNJ / UNJF thread mill

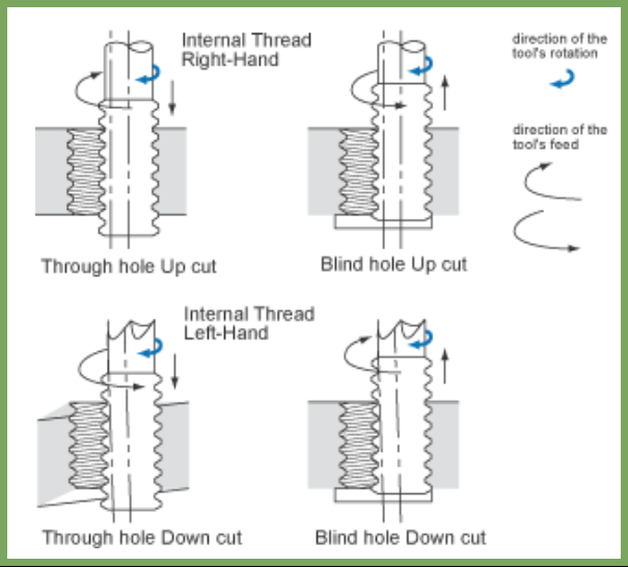

Thread milling supports internal and external threads, as well as left-hand and right-hand threads—often using the same tool.

Can Thread Milling Handle Blind Holes and Large Threads?

Yes—and this is where thread milling clearly outperforms tapping.

Blind holes:

- No bottoming tap required

- Full thread depth achievable

- Clean exit without chip packing

Large threads:

- Taps become impractical or unavailable

- Thread mills scale easily with diameter

- Controlled cutting avoids excessive torque

Thread Milling in Hardened and Difficult Materials

Thread milling excels in materials where tapping struggles or fails.

Suitable materials include:

- Hardened tool steel (HRC 58–68)

- Austenitic and duplex stainless steel

- Titanium alloys

- Nickel-based superalloys

Multi-pass thread milling strategies reduce cutting forces and thermal shock, significantly extending tool life.

How Are Thread Mill Speeds and Feeds Determined?

Thread mill cutting parameters depend on:

- Tool diameter and flute count

- Thread pitch

- Workpiece material

- Pass depth and strategy

Typical Starting Parameters (Solid Carbide Thread Mills)

Material | Cutting Speed (Vc) | Feed per Tooth |

Carbon steel | 80–120 m/min | 0.02–0.05 mm |

Stainless steel | 60–90 m/min | 0.02–0.04 mm |

Hardened steel | 30–60 m/min | 0.01–0.03 mm |

Titanium alloy | 40–70 m/min | 0.01–0.03 mm |

Final parameters should always be optimized based on machine rigidity and tool geometry.

How Is Thread Milling Programmed in CNC?

Thread milling can be programmed using:

- CAM system thread milling cycles

- CNC macro programs

- Manual G-code for advanced users

Key programming considerations:

- Entry and exit arc design

- Tool radius compensation

- Pitch synchronization

- Multi-pass depth control

Modern CAM systems simplify programming while maintaining full control over thread quality.

When Should You Choose Thread Milling Over Tapping?

Thread milling is the better option when:

- Tight thread tolerances are required

- Materials are hardened or difficult to machine

- Blind holes are involved

- Multiple thread diameters share the same pitch

- Scrap risk must be minimized

For many manufacturers, thread milling is no longer an alternative—it is the standard.

Final Thoughts: Why Thread Milling Is a Strategic Machining Choice

Thread mills are not just cutting tools—they are process enablers.

By combining flexibility, precision, and safety, modern solid carbide and indexable thread mills help manufacturers:

- Reduce tooling inventory

- Improve thread consistency

- Increase process reliability

- Lower total machining cost

As CNC machining continues to advance, thread milling will remain a core technology for high-value threaded components.