Spindle Taper Interfaces Explained: Which Tool Holder System Really Delivers Accuracy, Stability, and Productivity?

Modern cutting tools may differ in geometry, coatings, and carbide grades, but none of them can perform without a reliable spindle interface.

No matter how advanced the cutting edge is, machining accuracy ultimately depends on how securely and precisely the tool is connected to the machine spindle.

So why are spindle taper interfaces such a critical part of today’s CNC machining systems?

And why are manufacturers increasingly moving away from traditional tapers toward BT, CAT, and HSK systems?

This article takes a deep, practical look at the most common spindle taper interfaces, explains how they differ in real-world performance, and helps you choose the right system based on speed, rigidity, material, and application.

Why Does the Spindle Taper Matter More Than Ever?

At first glance, a spindle taper may look like a simple mechanical connection.

In reality, it directly affects:

- Runout accuracy

- Tool vibration and chatter

- Cutting stability at high RPM

- Tool life and surface finish

- Repeatability in automated tool changes

As spindle speeds increase and tolerances tighten, older taper systems struggle to meet modern machining demands. This is why advanced tool holder interfaces are now standard in CNC machining centers across aerospace, automotive, mold, and precision engineering industries.

1. Morse Taper (MT): Is There Still a Place for a Classic Design?

Morse Taper (MT) is one of the oldest spindle taper systems still in use today. It relies on self-holding friction rather than a drawbar-driven clamping force.

Key Characteristics of MT Interfaces

- Self-locking taper design

- Simple structure, low manufacturing cost

- Limited clamping force

- Manual tool changes

Where MT Still Makes Sense

MT interfaces are still found in:

- Manual lathes and drill presses

- Educational workshops

- Small, low-cost CNC machines

However, MT tapers are not ideal for high-speed or high-load machining. Under aggressive cutting conditions, micro-movement between tool and spindle can lead to poor surface finish and accelerated tool wear.

Bottom line: MT is functional, but largely outdated for modern CNC production.

2. CAT40: Why Is It the Most Common CNC Spindle Interface?

CAT40 has become one of the most widely used spindle taper standards in CNC machining centers worldwide.

What Does “CAT40” Actually Mean?

- Taper ratio: 7/24

- “40” refers to the nominal taper size

- Retention via pull stud and drawbar

- Designed for automatic tool changers (ATC)

Why Do Manufacturers Choose CAT40?

Feature | CAT40 Performance |

Rigidity | Balanced |

Maximum RPM | Medium to high |

Tool Change | Automatic |

Application Range | Very wide |

CAT40 offers an excellent compromise between rigidity, tool capacity, and machine size, making it suitable for:

- Aluminum machining

- General steel and stainless steel machining

- Plastics and composites

For many job shops, CAT40 is the default choice because it supports a broad range of cutting tools without excessive spindle mass.

3. CAT50: When Is More Rigidity the Only Option?

CAT50 uses the same 7/24 taper geometry as CAT40, but with a significantly larger taper body and contact area.

Why Go Bigger with CAT50?

CAT50 is designed for:

- Heavy roughing operations

- Large-diameter cutters

- High cutting forces

- Large workpieces

CAT40 vs CAT50: A Practical Comparison

Parameter | CAT40 | CAT50 |

Taper Size | Smaller | Larger |

Rigidity | Medium | High |

Typical RPM | Higher | Lower |

Best For | General machining | Heavy-duty cutting |

CAT50 excels in applications such as:

- Mold base machining

- Structural steel components

- Large aerospace parts

Trade-off: CAT50 provides superior rigidity, but at the cost of increased spindle mass and reduced maximum RPM.

4. BT30: Why Is BT30 Ideal for High-Speed Precision Machining?

BT30 is widely used in high-speed and high-precision CNC machining centers, particularly in Asia and Europe.

What Makes BT30 Different?

- Symmetrical flange design

- 7/24 taper ratio

- Excellent dynamic balance

- Optimized for high RPM

Typical Applications of BT30

BT30 is commonly used for:

- Precision aluminum parts

- Electronics and semiconductor components

- Medical and small mechanical parts

ISO30, INT30, and BT30 – Are They Interchangeable?

While ISO30, INT30, and BT30 share similar taper dimensions, they differ in:

- Retention knob design

- Drawbar compatibility

- Flange geometry

Important: Always verify machine compatibility before selecting a BT30-style tool holder.

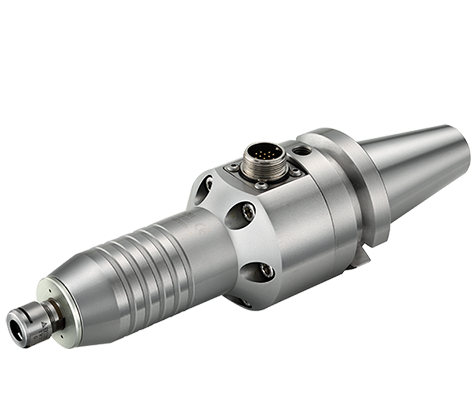

5. HSK: Why Is It the Benchmark for High-End CNC Machining?

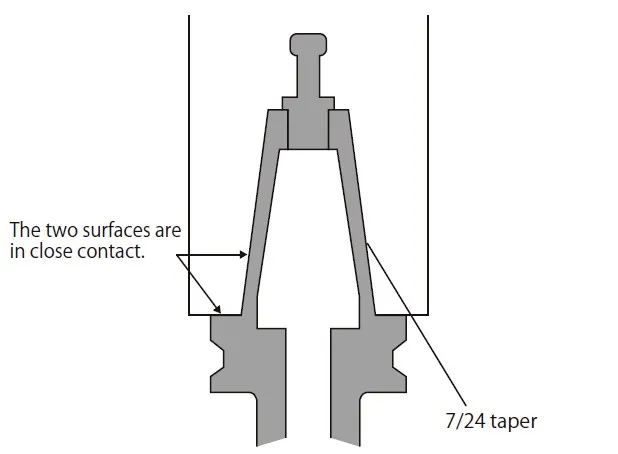

HSK (Hollow Shank Taper) represents a fundamental shift in spindle interface design.

What Makes HSK Technically Superior?

- 1:10 short taper

- Dual contact: taper + face contact

- Hollow shank expands under centrifugal force

- Extremely high repeatability

Why Dual Contact Matters

Unlike traditional 7/24 tapers, HSK tool holders achieve:

- Higher positional accuracy

- Better vibration damping

- Superior performance at high spindle speeds

Common HSK Types and Their Use

HSK Type | Typical Application |

HSK-A | General CNC machining |

HSK-B | Heavy-duty machining |

HSK-C | Special applications |

HSK-D | High-speed machining |

HSK systems are now standard in:

- Aerospace manufacturing

- High-precision mold making

- Advanced automotive production

How Do These Interfaces Compare in Real Machining Conditions?

Performance Comparison Overview

Interface | Max RPM | Rigidity | Precision | Best Use Case |

MT | Low | Low | Low | Manual / legacy |

BT30 | Very High | Medium | High | Precision & speed |

CAT40 | High | Medium | Medium–High | General CNC |

CAT50 | Medium | High | Medium | Heavy cutting |

HSK | Very High | Very High | Very High | High-end CNC |

How Should You Choose the Right Spindle Interface?

Ask the right questions before deciding:

- Are you machining aluminum or hardened steel?

- Is surface finish or material removal rate more critical?

- Do you need extreme RPM or maximum rigidity?

- Is automation and repeatability important?

There is no universal best interface—only the most suitable one for your application.

Final Thoughts: Why the Spindle Interface Defines Machining Quality

As cutting tools continue to evolve with advanced carbide grades and coatings, the spindle-tool interface remains the foundation of machining performance.

A high-quality tool holder system:

- Protects your cutting tools

- Improves process stability

- Reduces scrap and downtime

- Enables consistent, repeatable machining

Whether you are using BT, CAT, or HSK systems, understanding the mechanical principles behind each interface allows you to make better tooling decisions—and ultimately achieve better machining results.