How Does Helix Angle Really Affect Solid Carbide End Mill Performance?

A Practical, Data-Driven Guide for Choosing the Right Geometry

High-precision tools for efficient milling in a variety of materials.

Ideal for smooth and accurate routing with superior durability.

Robust and wear-resistant drills for high-speed, precise drilling.

High-performance end mills for stainless steel, ensuring precise, efficient, and durable machining.

Perfect for 3D contouring and finishing applications.

Precision end mills for aluminum, designed for smooth, efficient, and high-speed machining.

Utilizing advanced German-standard manufacturing, our tools ensure exceptional accuracy and long-lasting durability in every application.

Each tool is designed with cutting-edge technology to maximize operational efficiency, reduce wear, and extend tool life, providing optimal value for your investment.

Engineered for demanding applications, our tools deliver reliable and consistent results, even in the most challenging machining environments, ensuring smooth, precise cuts every time.

HNCarbide delivers high-performance CNC cutting tools engineered for precision and long tool life. Using premium solid carbide and selected HSS materials, our carbide end mills, carbide drill bits, spiral bits, router bits for aluminum and wood, and carbide inserts provide excellent wear resistance, stable cutting and smooth chip evacuation.

With optimized geometries for aluminum, steel, stainless steel and cast iron, plus advanced PVD / CVD coating options, our tools help you achieve higher feed rates, better surface finish and reduced machining costs. Custom and non-standard cutting tools are also available to meet your special profiles and OEM projects.

HNCarbide tooling is widely used in automotive, aerospace, mold & die, mechanical parts machining, electronics, and woodworking industries. Our carbide end mills for aluminum, stainless-steel carbide end mills, deep-hole carbide drill bits, and single flute spiral bits ensure efficient machining on CNC machining centers, drilling machines and routers.

Whether you need high-speed roughing, finishing of precision cavities, or clean edge cutting for panels and profiles, HNCarbide helps you improve productivity, extend tool life and keep your production stable and reliable.

High-quality high-speed steel (HSS) is selected as the raw material for taps, ensuring good wear resistance and toughness.

Precision cutting processes are used to cut the threads on the tap using CNC machines or specialized thread grinders, ensuring thread accuracy and sharpness.

Taps are coated with materials like TiN or TiAlN based on requirements, improving wear resistance, reducing friction, and extending tool life.

A Practical, Data-Driven Guide for Choosing the Right Geometry

A Deep Technical Guide to Center-Cutting Design, End Geometry, and Real Machining Performance

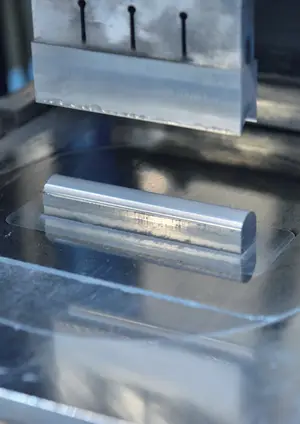

A Technical Guide to Tungsten Carbide Rod Manufacturing, Microstructure, Grades, and Coolant-Hole Rod Performance

WhatsApp us

Before you go, please note that we offer the most up-to-date industry research reports and the most comprehensive product catalogs, so please contact us if you are interested!

Before you go, please note that we offer the most up-to-date industry research reports and the most comprehensive product catalogs, so please contact us if you are interested!