Mastering Material-Specific Milling: The Top 10 Brands for Every Workpiece

Table of Contents

You can achieve precision, efficiency, and extended tool life with your material’s correct carbide end mill. Metal materials, whether aluminium, stainless steel, titanium, or hardened steel, require specific tool geometry and coatings to perform well. High-performance Brands: Brands like HNCarbide specialize in carbide end mills tailored for high-performance machining in particular materials, providing superior chip control, heat resistance, and tool longevity. Keep reading to know more about it.

Does Each Material Require a Different End Mill?

The unique properties of each different material determine how it should be machined.

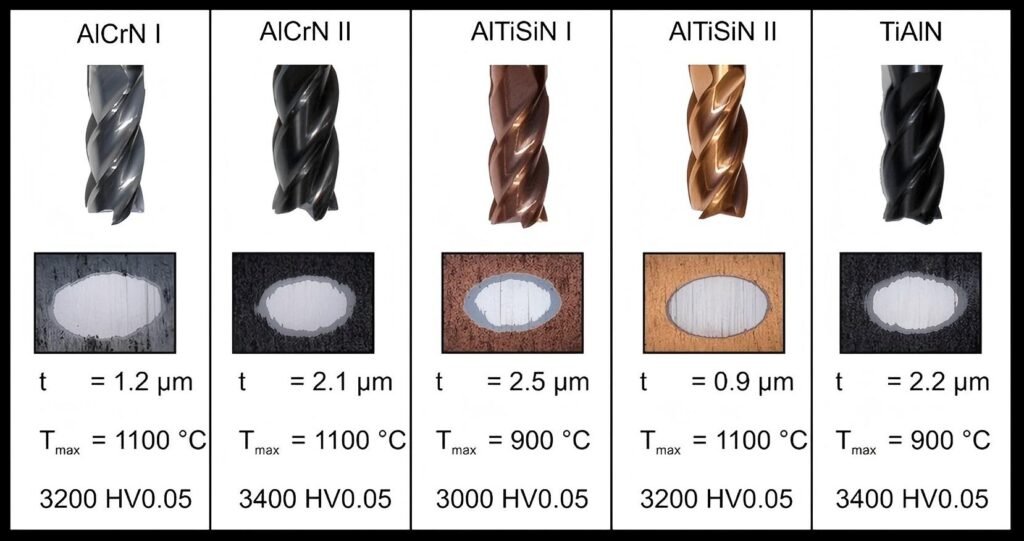

- Hardness & Wear Resistance:Ultra-durable, high-hardness carbide with advanced coatings (suchas TiAlN, AlCrN, etc.) to machine more complex materials such as titanium and tool steel that produce extreme heat and wear.

- Thermal Conductivity: Some materials, such as stainless steel, do not readily release heat, which can cause toolfailure. Heat-resistant coatingsand thoughtful coolant strategies are key to extending tool life.

- Chip Evacuation & Surface Finish: because aluminium generates long, gummyish chips that may potentially clog flutesand lead to a break. Polished-flute high-helix end mills resist chip weld-up and enhance surfacefinish.

This can lead to lousy surface quality, tool breakage, and poor machining, increasing costs and downtime.

Leading manufacturers are dedicated to creating custom end mills tailored for specific workpieces that enhance cutting speeds, tool life, and accuracy. Others, such as HNCarbide, combine precision engineering, micro-grain carbide, and cutting-edge coatings, giving machinists a reliable, high-quality tool for any material. The right end mill will help you run more efficiently, but it is also one of the few ways to unlock everything your machine has regarding speciality tools.

Top 10 End Mill Brands by Material

Choosing the proper end mill for the specific material is essential to producing excellent machining performance. Each material has challenges, and the leading manufacturers have engineered specialized end mills to tackle them. Here is a breakdown of the best end mill brands by material type, advanced technologies, and specialized capabilities.

Best End Mills for Aluminum

Emuge-Franken (Germany)

Emuge-Franken offers a range of single-flute end mills designed for high-speed aluminium machining. These end mills enable the utmost prevention of material build-up and smooth chip removal. The single-flute configuration allows for increased cutting speeds while generating very little heat, perfect for aluminium’s soft, highly ductile characteristics.

Harvey Tool (USA)

They are known for high-polish finish micro end mills specifically for aluminium machining. These tools are excellent for creating complex cuts and detailed features. Their micro-polish coatings guarantee less cutting friction, resisting the material’s tendency to adhere to the tool, as is typical in machining aluminium. A precise design for their tools suggests it gives you an excellent surface finish and a long tool life.

Tapers and End Mills for Stainless Steel

Mikron (Switzerland)

Mikron’s anti-adhesion coatings, with patented properties, made them a brand of choice for stainless steel machining. These coatings dramatically inhibit built-up edge (BUE) formation, impacting tool performance and workpiece quality. Preventing material from sticking to the tool can be challenging, especially during stainless steel operations, but Mikron’s tools shine at this, allowing good surface finishes at high speeds.

OSG (Japan)

OSG’s end mills, coated with TiAlN, which resists high temperatures, are designed for the extreme temperature (and wear) generated during stainless steel machining. Their tools are known for high wear resistance, making them suitable for continuous cutting at high rotation speeds. OSG designs also emphasize chip evacuation and heat diffusion for tool longevity and workpiece quality.

End Mills for Titanium & High-Temperature Alloys

Seco Tools (USA)

Seco Tools is a premier producer of cutting-edge machining tools for titanium and high-temperature alloys. Their titanium end mills are designed to work through the heat and stress of machining these problematic materials. Seco’s coatings reduce the high temperatures created during cutting, extending tool life and increasing performance. Optimizing chip removal is another critical aspect of titanium machining that their tools are adapted to.

Guhring (Germany)

Unique edge geometry for Guhring’s titanium machining tools adapts to the high thermal conditions of titanium alloys to keep the tools cutting. High-tech coatings, like TiAlN, are used in their tools, providing better heat resistance and less wear. Guhring’s designs also include features that enhance chip flow to reduce the risk of tool failure when machining challenging titanium alloys.

Differences Table: Material-Specific End Mills

Brand | Material | Tool Type | Key Features | Coating/Technology |

Emuge-Franken | Aluminum | Single-flute end mill | High-speed cutting, efficient chip removal, reduced material build-up | High-performance coatings |

Harvey Tool | Micro end mills | High-polish finish, precise cuts, excellent surface finish | Micro-polish finish coatings | |

Mikron | Stainless Steel | End mills with anti-adhesion | Excellent chip removal, prevents BUE formation, smooth cutting | Patented anti-adhesion coatings |

OSG | Stainless Steel | End mills with TiAlN coating | High heat resistance, extended tool life, optimized chip evacuation | TiAlN heat-resistant coating |

Seco Tools | Titanium & High-Temp | High-performance end mills | Specially designed for titanium, optimized chip removal, extended tool life | High-temperature coatings |

Guhring | Titanium | Specialized edge geometry | Improved chip flow, heat resistance, specialized cutting edge for titanium alloys | TiAlN coating |

Best Practices for Maintaining Material-Specific End Mills

Selecting the correct end mill is critical to achieving quality results, but proper care of these tools is also vital for their long-term performance. But there are a few things you can do to ensure your material-specific end mills remain in top shape:

Proper Tool Storage

To avoid rusting, end mills should be kept in a dry, clean area when not being used. Tools or a hardware store/tool rack should be stored in their cases to prevent physical damage and contamination. Coated tools, in particular, must be handled with extra care to avoid scratches or nicks that can compromise performance.

The Importance of Regular Check and Keep Clean

Check the tool periodically for wear or damage, particularly after being used for long periods. Cleaning end mills after each usage is essential to prevent any material buildup or chips that might have been harboured. This will also assist with chip evacuation to maintain tool performance. Cleaning with ultrasonic waves or brushing with a soft wire brush without scratching the coating can facilitate the elimination of any debris.

Regrinding and Resharpening

One approach to extending the useful life of end mills is regrinding them. Always follow the manufacturer’s recommendations on how often a tool can be reground before it loses effectiveness. Resharpening restores the original cutting geometry of the tool, returning it to optimal efficiency. Regarding high-end brands such as Seco Tools or Guhring, their tools can be regarded several times before replacement.

Avoiding Overloading

Excessive cutting forces can result in premature tool wear and fracture. Feeding the tool at the proper rates and keeping the correct cutting speeds and depth of cut is essential so we do not overload the tool. This is designed to minimize the risk of tool breakage and facilitate efficient machining by using the manufacturer’s recommended settings for each material type.

The Role of Tool Coatings in Material-Specific Milling

The coatings are a modern end mill design’s most important advanced technology feature. This tool protects the tool from wearing and tear and increases cutting function. Here’s how each coating works for material-specific milling:

Aluminium Milling:

AlTiN (Aluminum Titanium Nitride): Improvements in coating hardness help to inhibit and reduce the edge points that cause friction wear , particularly in soft materials such as aluminium. Silicon helps to enhance tool life since it improves heat resistance in the substrate for surgical tasks like high-speed aluminium machining.

Stainless Steel Milling:

TiCN (Titanium Carbonitride) is used to machine stainless steel , as it reduces the material’s adhesion to the tool. The coating prevents built-up edge (BUE) formation, which hinders clean chip removal and shortens the tool’s life. It provides an extra millisecond of life in extreme operations.

Titanium Milling:

TiAlN (Titanium Aluminum Nitride): An outstanding heat-resistant coating suitable for titanium and other high-temperature alloys. TiAlN can tolerate high temperatures in titanium machining so that the parts formed do not break down in the cutting tool.

As the need for machining increasingly complex and exotic materials mounts, tool coatings will develop. The coating industry is and will be the research direction for some time, with a multi-layer composite coating that is wear-resistant, heat-resistant, and anti-adhesion.

How to Optimize Milling Operations Based on Material Type

Optimizing milling operations begins with nailing down the details of the material and tool. Some optimization tips for common materials are as follows:

Aluminium Optimization:

- Methods: Use high-speed, single-flute end mills to minimize the build-up of materials on thecutting edge. These end mills are well suited for speed and chip-thinning operations and will help you achieve high feed rates.

- Use a moderate feed rate and high cutting Keep the tool moving to prevent chip recutting. A positive rake (forward rake) will reduce cutting forces and benefit finishing operations.

Stainless Steel Optimization:

- Employing multi-flute end mills with an acutecutting edge can improve tool stability without sacrificing precision. Upping the flute count helps maintain the integrity of the surface finish while promoting chip removal.

- Coolant can achieve low temperatures between the tool andthe workpiece. This enhances the tool’s life and aids in attaining a finer surface finish.

Titanium Optimization:

- The cutting speed for milling titanium is slower, and the feed rates are higher, which decreases heat production and increases tool Consistent chip thickness should be maintained, and high-performance end mills should have advanced coatings.

- Empirically tune the cutting-edge geometry for the particulargrade of titanium alloy being machined. Specialist tools with novel geometries explicitly designed for titanium alloys can vastly decrease site wear.

Future Trends in Material-Specific Milling Tools

Thanks to the maturity of ever-expanding techniques, the future of milling tools looks like they will only become more sensitive to the machined material. So here are some trends to expect:

Materials for High-Performance Coatings

New intelligent coatings would enable the tools to adjust to various materials and cutting environments. The coatings themselves will respond to temperature changes, chemical reactions and wear, so a tool will continually be optimized for the job.

Tools Additive Manufacturing

Also, the future of milling tools will change with additive manufacturing (3D printing). Custom tools ideally suited to a material or workpiece can be printed on demand, streamlining machining operations. This technology will enable manufacturers to make tools with advanced geometries that traditional techniques won’t produce.

Artificial Intelligence & Robotics

By and large, AI and automation will majorly impact milling operations. AI will facilitate more accurate and efficient milling processes, especially those used for inherently variable materials, such as titanium or superalloys, [to] automatically adjust cutting parameters and predict tool wear.

Conclusion

Choosing the right end mill is critical to successful machining; know the requirements of the material you’re working with. Well-known companies such as HNCarbide, Emuge-Franken, Harvey Tool, Mikron, OSG, Seco Tools and Guhring have made specialized tools for machining in aluminium, stainless steel and titanium, guaranteeing that manufacturers realize excellent surface finishes, tool life, and performance in use. Among all the options, HNCarbide has topped the charts with its vast offerings, experience and customer service. From 1 4 end mill, four flute end mill to 1 ½ end mill, 1 ¼ end mill, you can get every tool at HNCarbide, becoming everyone’s favourite end mill manufacturer. Choosing material-specific tools enhances machining efficiency and minimizes tool wear, material adhesion, and overheating risks. The proper choice of end mill can also improve machining operations’ quality and cost efficiency.

FAQs

Why is selecting the most appropriate end mill for diverse materials essential?

Selecting the most suitable end mill for specific materials guarantees higher cutting rates, better surface finishes, and increased tool life. Due to the hardness, thermal conductivity, chip evacuation requirements, and other unique characteristics of different materials, specialized tools are needed to achieve the best performance.

Which end mill is suitable for aluminium machining?

Emuge-Franken single-flute end mills can be used for aluminium machining. They offer fast chip removal, minimize material build-up, and allow for high-speed cutting, resulting in smooth finishes and extended tool life.

What is the Impact of Tool coating on Material-specific Milling

Tool coatings, such as TiAlN (for titanium) or TiCN (for stainless steel), enhance wear, heat resistance, and chip removal. When machining hardened materials, you must coat the tools to increase tool life and performance, especially at high-speed or high-heat conditions.

What should you think about when picking an end mill for titanium?

So, when picking your titanium end mill, you’ll want to consider heat resistance, cutting speed, and the specific tool geometry for titanium. Tools used for titanium must have special coatings (such as TiAlN) and geometries that allow them to withstand high cutting temperatures and promote optimal chip evacuation during the machining of this material.