Italy’s Leading Drill Bit Innovators – Powering Precision across Europe

Italy is now an essential leader in European carbide drill bit manufacturing. Germany is still Europe’s strongest industrial giant, but numerous German firms now depend on Italian drill bit producers. Italian drill bit producers are reliable for their quality output, dependability, and refined technology. They are not merely suppliers; they are partners who increase production speed, precision, and quality to be improved.

This article considers Italy’s leading carbide drill bit producers, how they facilitate German and European industries, and why their products are now critical in high-performance, precision-based manufacturing facilities.

Italy’s Industrial Development and Precision Tooling

Italy has a rich manufacturing heritage. Its industries have, over the years, become renowned for producing extremely accurate tools that are important in the automotive, aerospace, energy, and advanced machining industries. The Italian drill bit manufacturers have capitalized on this and now dominate contemporary, high-tech toolmaking.

Italian drill bits are relied on in Germany because they obtain important certifications such as DIN and VDMA. Italian vendors also provide quicker delivery and greater flexibility in logistics than most other global competitors. This has made Italian drill bit manufacturers vital partners to German factories, forming robust, dependable supply chains based on precision and quick service.

Why Drill Bit Technology Is Important in Large Industries

Drill bits serve to do far more than create holes. They are necessary for maintaining factories and ensuring all parts are produced correctly.

Automotive Industry

German automobile manufacturers such as BMW utilize carbide drill bits to drill hard materials such as engine blocks and suspension components. The tools must be durable.

Aerospace Industry

This industry requires sturdy carbide drill bits to make precise small holes in light materials such as composites and titanium. The drill bits should be heat-resistant and highly durable.

Energy Industry

Power plants and pipeline companies employ carbide drill bits for drilling deep into hard metals. The bits can withstand intense temperatures and pressures without shattering too fast.

In all these industries, employing the correct drill bit saves time, minimizes costs, and maintains production smoothly.

Italy’s Strength in Carbide Drill Bit Manufacturing

Italy’s metalworking heritage began in the Renaissance, but its contemporary success with CNC tooling began after World War II. Lombardy and Veneto became the lead regions for precision engineering, combining craftsmanship with sophisticated automation.

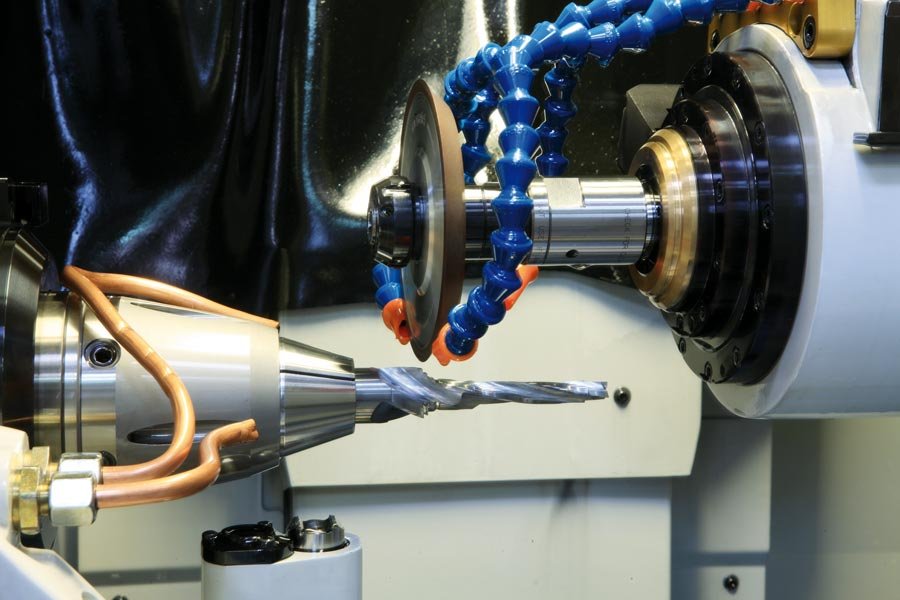

Investment in CNC and Coating Technology

Presently, Italian drill bit producers employ sophisticated five-axis CNC grinding, automated inspection systems, and unique coatings such as PVD and CVD. This enables them to deliver drill bits that surpass Germany’s highest industrial standards.

Firms such as Cruing, HTT Centro Affilatura, and Tungsten Tools Italia concentrate on enhancing tool life, chip removal designs, and improved coatings such as AlTiN and TiCN. Their high-quality drill bits are now extensively employed by German firms.

Top 5 Italian Drill Bit Suppliers Powering Europe

Top 5 Italian Drill Bit Suppliers Powering Europe

1. Cruing Group – Premium Carbide Drill Bits for Aerospace and Automotive

Specialty

Cruising Group is the most advanced carbide drill bits manufacturer in Italy. Their specialty lies in aerospace grade solid carbide drill bits with the best cutting performance. They have applications in the widespread manufacture of high value aerospace parts and intricate automotive components.

Product Highlight

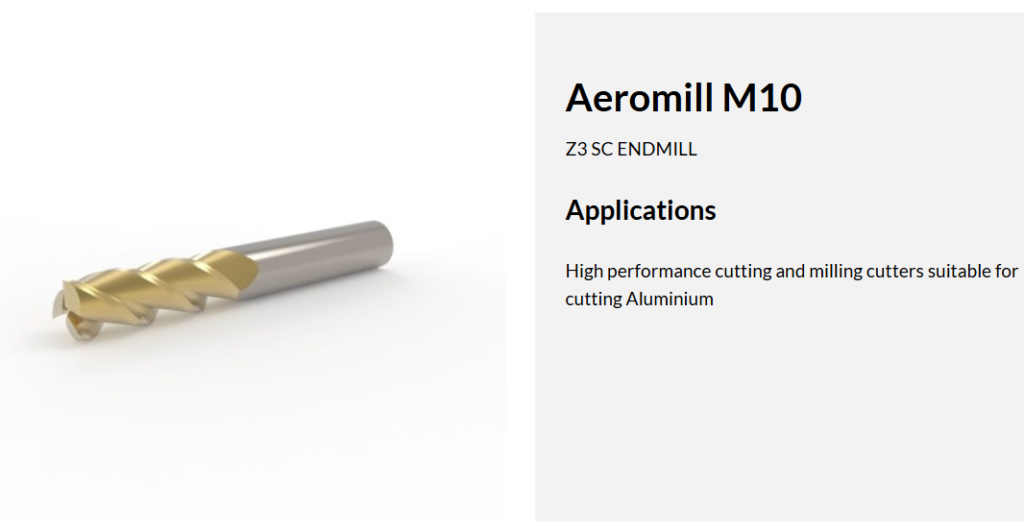

Their AeroDrill SC series has coolant holes, 5×D drilling depth and coatings for aluminum, titanium and composite drilling optimized. These drill bits provide superior chip evacuation, lower heat generation and longer tool life.

Competitive Edge

Cruing is EN 9100 certified, which is important for aerospace suppliers. The direct working relationship of the company with Tier 1 German aerospace and automotive companies makes it stronger in the German market. Several factories rely on Cruing for core parts where drilling needs to be coolant-fed for structural integrity.

Key Applications:

- Drilling structural airframe components

- Accurate coolant-fed drilling in aluminum and titanium.

- Automotive lightweight structural parts

Cruing’s capability to provide carbide drill bit solutions specifically suited to challenging applications makes it a go-to partner for high-precision German industries.

2. HTT Centro Affilatura – High Precision Solid Carbide Drills for Automotive Manufacturing

Specialty

HTT Centro Affilatura is a top solid carbide drill bit producer focused on automotive and general mechanical uses. They are specialists in deep hole drilling and bespoke drill bit geometries.

Product Highlight

HTT’s solid carbide reamers and drills can be built to precise tolerances for multi diameter operations, cylinder head drilling and crankshaft machining. Its solutions lead the industry in drilling hardened steel and high strength alloys found in automotive components.

Competitive Advantage

HTT’s close fit into German automotive supply chains is one of their strengths. They provide rapid lead times, versatile production runs and special carbide drill bits customized to meet the particular demands of German OEMs and Tier 1 suppliers.

Major Applications

- Machining of cylinder head and engine block

- Drilling of crankshaft oil passage

- Drilling of the transmission housing

Their capability to provide speedy supply of solid carbide drill bits 3/8 size, 1/4 carbide drill bits and deep-hole custom tools makes them a good partner for German automotive plants that need high volume production effectiveness.

3. Tungsten Tools Italia – Leaders in Composite and Exotic Material Drilling Specialty

Tungsten Tools Italia is renowned for research and development led breakthroughs in drill bit technology and specializes in the drilling of advanced composites, CFRP and difficult material stacks.

Product Highlight

The THP 2.910 ST and TD L3 series are designed specifically for composite, titanium and multi layer stack drilling. They offer low thrust forces, less delamination in CFRP and excellent heat resistance.

Competitive Edge

Tungsten Tools is recognized for producing high-performance drill bits which surpass most global brands when it comes to challenging materials to work with. Their goods are renowned in Germany’s aerospace and wind industry where quality and accuracy are paramount.

Key Applications

- Assembly of aerospace fuselage

- Drilling composite structures in wind turbine

- Multi layer stack drilling (titanium, CFRP, aluminum)

Their specialization in creating carbide drill bits for drilling hardened steel and composites places them at the top of the list for German engineers keen on lightweight, high-strength products.

4. Ital Tools – Cost-Effective Supply of Carbide Drill Bits with International Presence

Specialty

Ital Tools is a highly versatile drill bit supplier with both carbide and HSS (high-speed steel) drills available for industrial use, with a significant presence in furniture, heavy machinery, and metalworking industries.

Product Highlight

Their collection comprises ISO-certified carbide drill bits that are a mix of precision and affordability. Ital Tools also manufacture special solid carbide drill bit size charts, which provide tool selection flexibility and quick response to custom-specific requirements.

Competitive Edge

Ital Tools has a reputation for having an export-focussed attitude, flexible production capacity, and flexibility in meeting small minimum order quantities. German manufacturing purchasers value their responsive lead times and price competitiveness for bulk drilling operations.

Major Applications

- General-purpose industrial drilling

- Metal furniture production

- Rapid turnaround batch production

With an emphasis on practical applications and drill bit supply reliability, Ital Tools has a well-deserved reputation as a reliable source for European manufacturers seeking consistent quality at competitive prices.

5. Krino Spa & Milanese Utensili – Micro Carbide Drill Bit Specialists

Specialty

Krino Spa, along with Milanese Utensili, specializes in precision microcarbide drill bits for electronic, watchmaking, and micro-mechanical industries.

Product Highlight

They provide ultra-small sizes of carbide drills, such as 1/8 carbide drill bits and 3/16 carbide drill bits, with close tolerances and ultra-fine grinding that provides low vibration, high concentricity, and low runout.

Competitive Edge

Their companies are focused on vibration micro-drilling solutions that are essential for printed circuit board production, electronic connectors, and miniaturized assemblies. Their products find extensive applications among German electronics manufacturers who need flawless precision at micro levels.

Key Applications

- PCB and micro-electronics drilling

- Watchmaking components

- High-precision micromechanics

Krino and Milanese Utensili’s dedication to solid carbide micro-drilling makes them leaders in a niche but highly valuable sector of the German market.

How Italian Brands Compete Globally

Italian manufacturers focus on precision, reliability, and customization to meet strict European standards.

- They offer flexible production for both small and large orders, making them suitable for specialized industries.

- Strong in high-performance applications like aerospace, automotive, and advanced composites.

- Heavy investment in R&D, advanced coatings, and CNC technologies ensures cutting-edge products.

- Italian brands are known for quick adaptation to design changes and customer-specific requirements.

- They offer total cost advantages by improving tool life and reducing machine downtime.

- Competitive globally by combining quality, customization, and responsive service.

Strong Pricing, Logistics, and Supply Chains

Italian drill bit makers are now top choices for German industrial buyers because they offer excellent quality, flexible supply chains, and good prices.

Near-Shoring Advantages: Faster Deliveries

With global shipping delays, German companies prefer nearby suppliers like those in Italy. Italian drill bit makers offer:

- Much shorter lead times: 1–3 weeks from Italy vs. 8–12 weeks from Asia

- Quick response to urgent orders and design changes

- Lower shipping costs and reduced environmental impact

Italian suppliers are ideal for German manufacturers moving toward more local sourcing and faster deliveries.

Local Warehousing in Germany

Some Italian drill bit manufacturers now keep inventory in Germany to support just-in-time (JIT) delivery. This helps German factories:

- Keep less stock in-house

- Get fast deliveries

- Reduce costs and improve flexibility

Local warehouses are especially helpful for custom carbide drill bits that aren’t available off the shelf.

Competitive Pricing with Customization

Italian manufacturers offer:

- Better prices on complex, custom drill bits compared to some other European suppliers

- Lower total costs thanks to long tool life and fast regrinding services

- Flexibility for low- to mid-volume orders, which is key for custom or short production runs

This makes Italian suppliers a smart option for German factories that need specific solid carbide drill bit sizes like 3/8 or 1/4 inch.

Quality and Certifications

Italian drill bit manufacturers meet important European quality standards:

- ISO 9001 and ISO 14001:Quality and environmental certifications

- VDMA Memberships:Alignment with German industrial standards

- Aerospace Certifications: Companies like Cruing are certified for aerospace (EN 9100)

These certifications ensure smooth cooperation with German companies and make Italian suppliers easy to integrate into strict procurement systems.

Key Advantages of Italian Drill Bit Suppliers

Advantage | Description |

High Precision | CNC-ground with ±0.01 mm tolerances |

Advanced Coatings | AlTiN, TiCN, and DLC coatings for tough materials |

Efficient Production | Full DIN and VDMA compliance |

Flexible Logistics | Local inventory in Germany for fast delivery |

Customization Options | Special geometries for unique materials |

Practical Applications

- Automotive:Solid carbide drill bit size 3/8 and carbide 1/4 drill bit for deep drilling in engine blocks and suspension parts.

- Electronics:1/8 and 3/16 carbide drill bits for precise PCB drilling.

- High-Strength Steel:Carbide drill bits with special coatings for drilling hardened steel.

- Furniture & Industry:Ital Tools supplies reliable, cost-effective drill bits for wood, aluminum, and steel composites.

Italy’s Growing Role in European Tooling

Italian drill bit manufacturers are now leading players in Europe’s industrial tooling market. As supply chains move closer to home and German companies seek flexible, fast, and reliable partners, Italian suppliers like Cruing, HTT, Tungsten Tools Italia, Ital Tools, Krino, and Milanese Utensili are in high demand.

Their solid carbide drill bit size charts, advanced coatings, and expertise in custom tools make them globally competitive. Italian companies are also leading in sustainability, offering recyclable packaging, energy-saving designs, and regrinding services to extend tool life.

Conclusion

Italy’s drill bit innovators are shaping the future of European manufacturing. Their precision, durability, and flexibility are helping German industries succeed. Whether you need solid carbide drill bits, advanced coatings, or custom designs, Italy’s top drill bit manufacturers are excellent partners for today’s precision-driven factories.