Deep Hole Drilling: Challenges, Solutions, and the Role of Advanced 3D/5D Drills

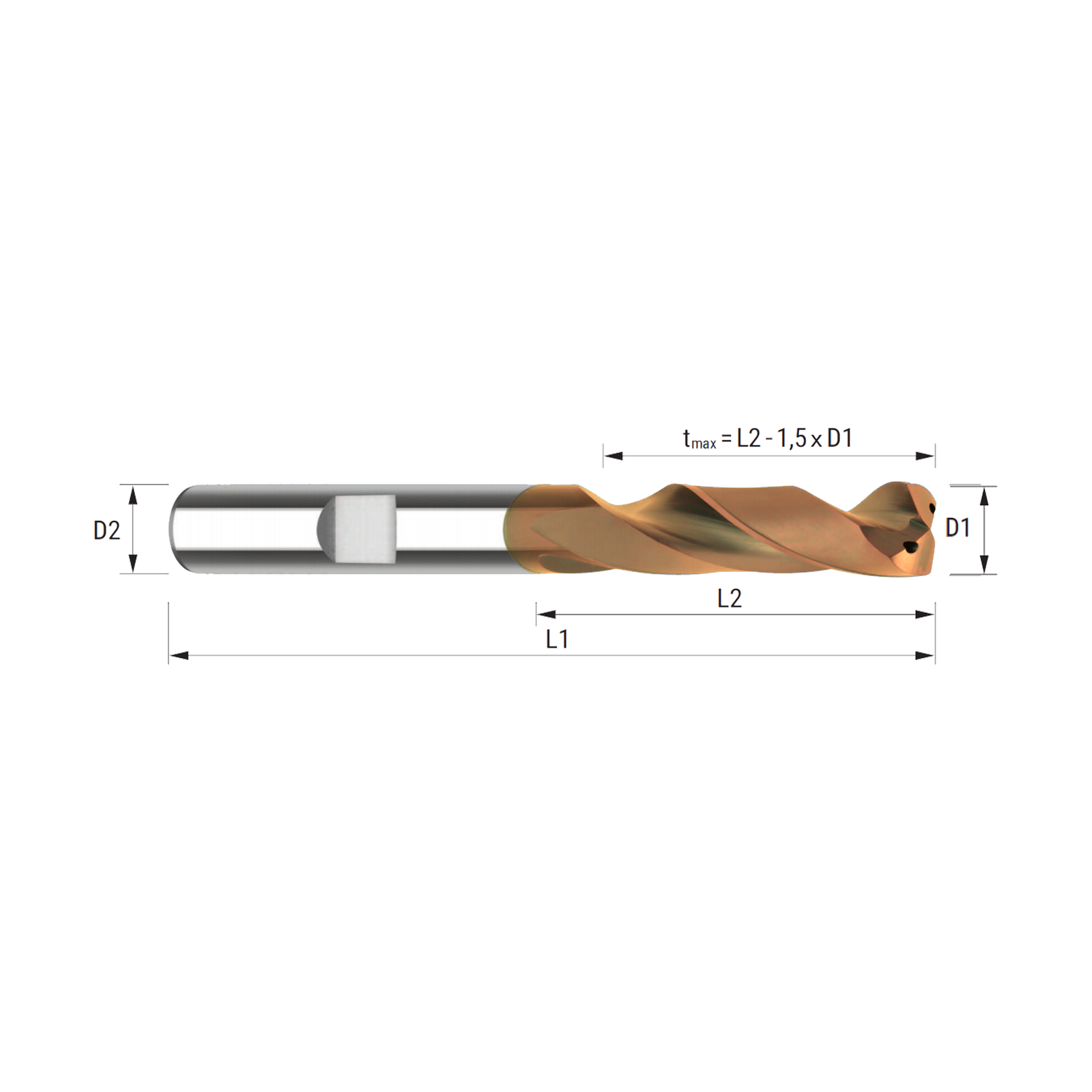

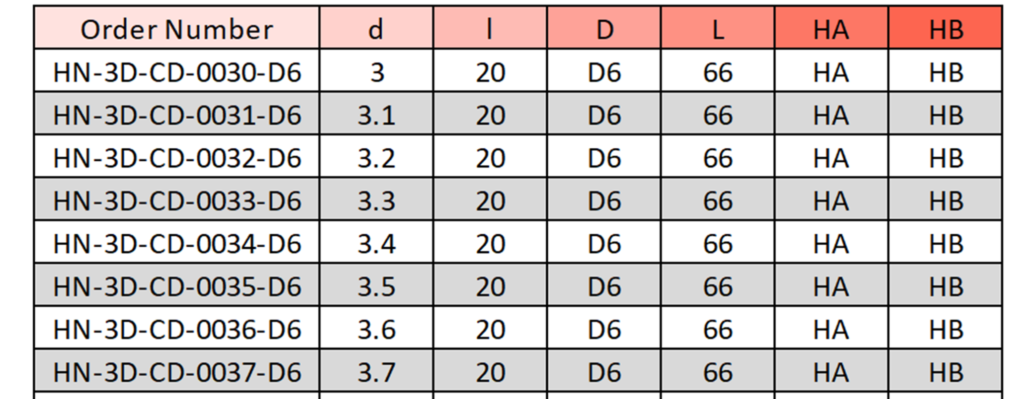

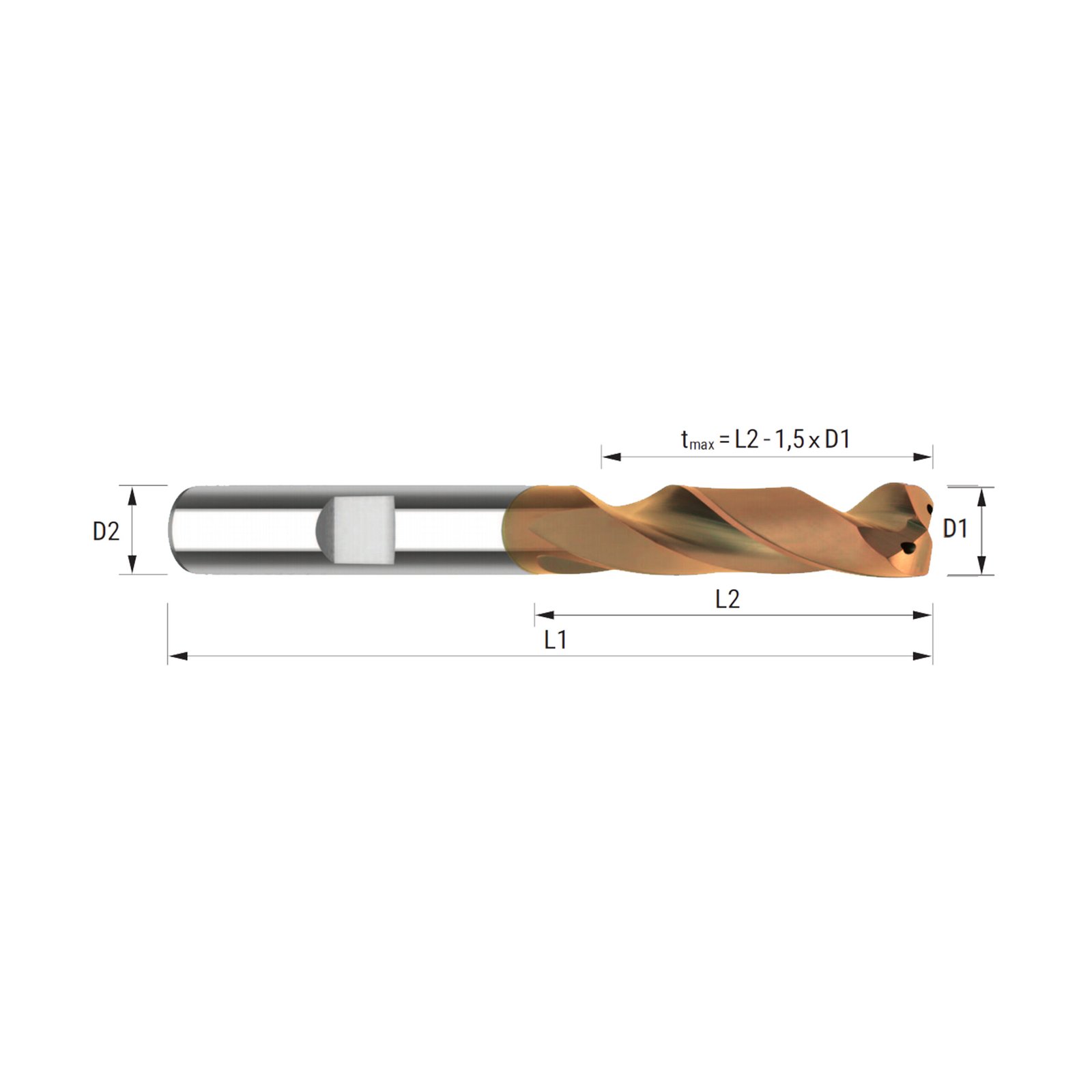

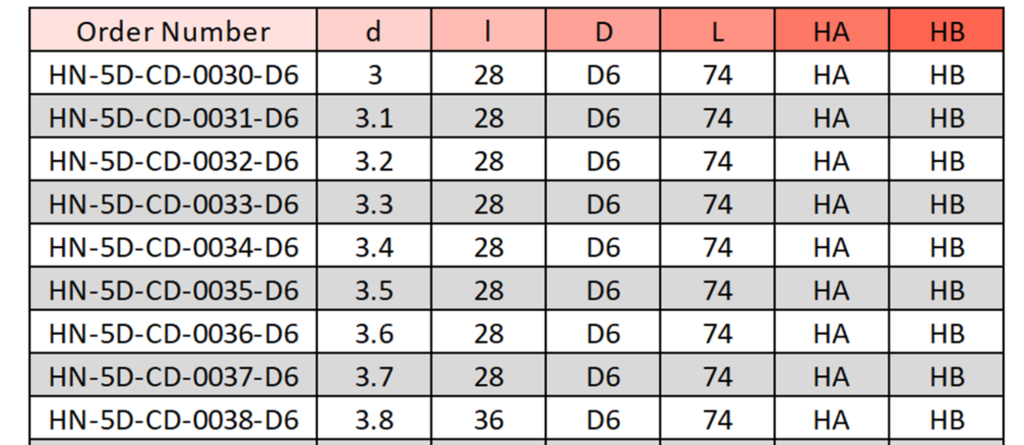

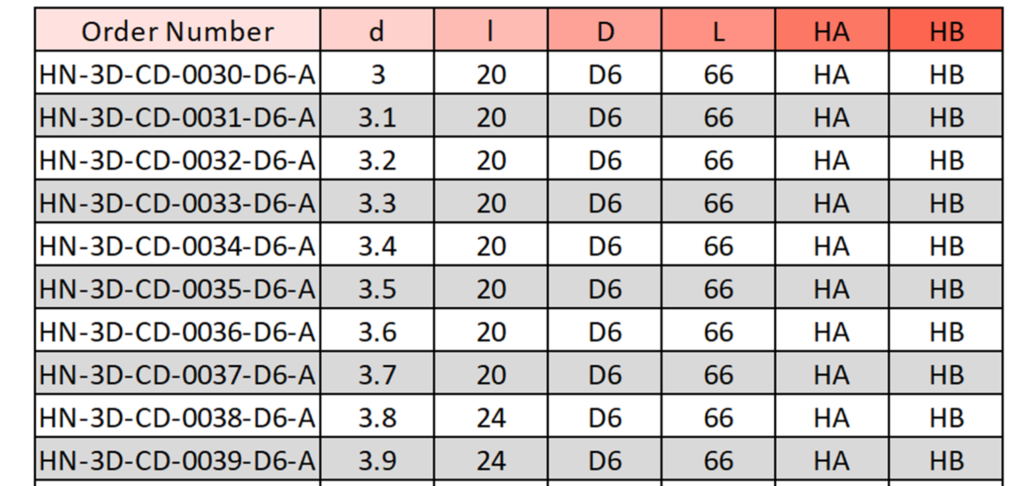

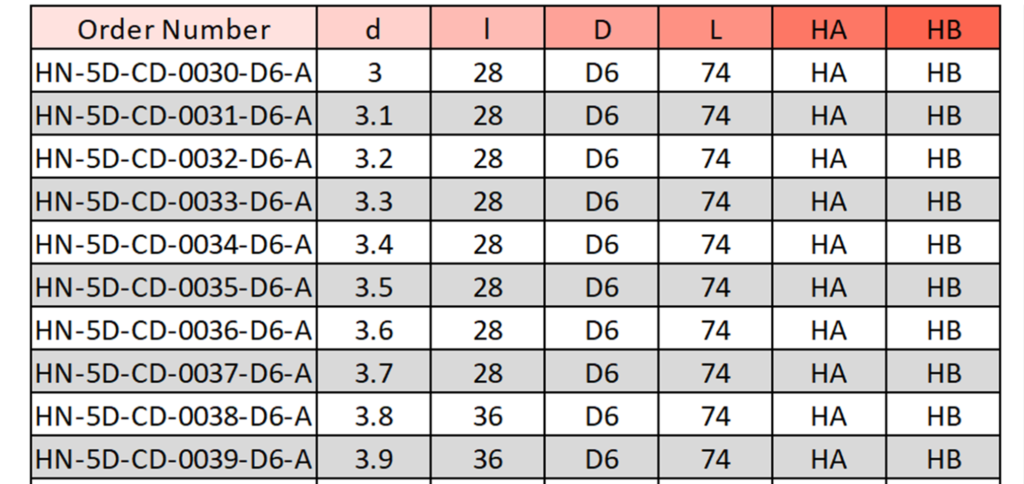

Deep hole drilling beyond 8–10×D faces chip evacuation, heat, and stability issues. This guide reviews materials, tool geometry, coatings, coolant systems, cost efficiency—and introduces HNCarbide’s 3D/5D carbide drills with internal/external coolant for reliable precision machining.