Imperial End Mills: The Secret to Their Lasting Market Presence

Table of Contents

Inch Milling Cutter Size System and Applicable Standards

Precision machining applications around the world heavily rely on imperial end mills to fulfill their operational needs. The inch milling cutter size system operates in tandem with North American markets that use standard measures of 1/4 end mill, 1 1/4 end mill, 1 1/2 end mill and 1/8 end mill. Manufacturing processes benefit from standardized end mill dimensions because they provide better operational efficiency while ensuring parts can replace each other.

Pursuant to globally adopted standards of BS (British Standards) and ANSI (American National Standards Institute) production and performance of end mills remains consistent and dependable. The industry specifications which demand precise custom end mills focus heavily on these standards for achieving high-performance machining objectives. HNCarbide produces custom end mills together with best metal cutting tools while following industry standards that enable end products to perform optimally across manufacturing environments.

Standardized measurements provide manufacturers with better inventory control and enables them to achieve smoother production methods. A standardized measurement system enables businesses to grow their operations efficiently because it eliminates compatibility problems. End mill supplier procurement becomes easier for industries because standard measures help them obtain best metal cutting tools precisely designed for their specific machining operations.

Importance of Standardized Sizes

Existing machine setups integrate more easily with three standardized end mill sizes including 1/4 end mill, 1 1/2 end mill, and 1 1/4 end mill. Standardized end mills contribute to better industrial flexibility due to their purpose in handling intricate machining operations. Standardized measurements help manufacturers decrease their expenses through the implementation of interchangeable cutting tools which can be applied across all their production applications.

Main Application Industry Analysis

Automobile Manufacturing

Pre-production of high-precision automobile components relies upon North American industrial usage of imperial end mills which incorporates British fastening systems. Manufacturers continue to expand their automobile operations which leads to increased requirements for specially designed end mills for unique machining tasks. 4 flute end mills and 2 flute end mills serve the automotive industry because they provide efficient metal cutting across various metals.

Very detailed precision standards for automobile components matter because they boost safety together with operational endurance. Best metal cutting tools enable manufacturers to fulfill quality control standards and optimize their operations efficiency. The integration of technological progress enables CNC machine tools and robotic automation to work more efficiently with automotive end mills which results in fast and precise manufacturing of parts.

Modern automobile manufacturing strongly focuses on using aluminum and carbon composites as lightweight materials beyond basic metal fabrication techniques. Manufacturers now require specialized custom end mills to efficiently work with these materials because the industry transition demands tools that minimize tool wear. The combination of advanced coatings and specific end mill geometries ensures stability when processing present-day materials in manufacturing operations.

The automobile industry chooses imperial end mills because of their sustainability capabilities along with cost-efficient nature. The industry demand for best metal cutting tools that blend durability and wear resistance has become essential because manufacturers must reduce waste and maximize energy efficiency and sustainability during production. The strategic implementation of premium custom end mills gives businesses extended tool performance together with minimized operational interruptions that yield superior machining output.

Mold Manufacturing

Export-oriented mold processing requires imperial end mills as a fundamental component due to its essential role in supplying production run companies throughout Europe and the United States. Mold-making benefits from custom end mills which offers both accuracy along with endurance and operational effectiveness during the process of shaping complex mold structures. High-quality production of 1 1/4 end mills and 1 1/2 end mills results in superior machining results within this sector.

The manufacturing industry of mold tools requires tools that feature enhanced wear resistance capability together with extended tool lifetime. Customers can obtain custom-made end mills from American end mill producers that work effectively on different mold materials like hard steel along with aluminum and plastic. The increasing requirement for precise mold production across aerospace, electronics and medical product fields creates more demand for top-quality end mills suppliers.

Advanced mold productions rely on growing requirements from customers for intricate and complex mold designs. The continuing growth of consumer electronics and medical devices industries propelled the need for ultra-precise customized end mills because they require intricate part dimensions. The mold industry adopts TiAlN (Titanium Aluminum Nitride) coated high-performance end mills which provide longer tool life and shorter manufacturing cycles.

The fast progress of injection molding together with die-casting technologies drives the market demand for best metal cutting tools. Manufacturers need continuous innovations for their imperial end mills to achieve improved productivity together with enhanced surface finishing quality. By working with companies like HNCarbide producers of mold equipment can maintain both high quality standards and production efficiency during multiple production phases.

Global Market Demand Trends

Manufacturers worldwide rely on accurate machining which drives up the need for optimal imperial end mills. When industries use CNC technology and implement industrial automation they actively look for high-performance end mill manufacturers centered in the USA to fulfill their cutting-edge solution requirements.

The end mills market receives strong support from the rapid advancement of infrastructure coupled with industrial development in emerging economies. As various manufacturing facilities expand across Asian and South American regions the requirement for top metal cutting tools rises accordingly. The transformation to global standards stresses the need for acquiring top-quality imperial end mills from international standards.

The end mills market experiences changes through ongoing advancements in material science. Advanced custom end mills that effectively process new alloys and engineered materials and composite materials are necessary because such materials have become increasingly common. Nanotechnology advancements have improved end mill functionality because they accelerate tool development improvements which leads to higher durability and enhanced precision along with operational efficiency.

Growth of CNC Machining and Automation

CNC machining technology brought about a substantial increase in the need for end mills which deliver advanced cutting performance. Industrial operations are purchasing customized end mills which provide increased durability along with precision so they can reach superior productivity along with decreased production costs. Market demand for best metal cutting tools intensifies due to manufacturing automation adoption enabling constant improvement in cutter designs and materials used.

Expansion of Aerospace and Defense Industries

The aerospace defense industry needs exceptionally sturdy as well as precise cutting tools for its operations. The manufacturing of critical aircraft components requires essential end mills including 1 4 end mill and its variations up to 1 1/2 end mill. Company suppliers of end mills need to respond rapidly to increasing market demand for high-quality cutting tools with advanced coatings and geometries as these industries achieve global expansion.

Key Factors in Selecting Inch Milling Cutters

Material & Coating (HSS vs. Carbide)

How well materials suit end milling operations determines both end mill functioning and their operational life. The two main materials for constructing best metal cutting tools consist of high-speed steel (HSS) and carbide. HSS offers flexible and affordable options although carbide delivers unmatched hardness with better heat tolerance as well as resistance to wear which makes it perfect for high-speed machining operations.

Carbide end mills serve industries having strict precision requirements in aerospace and medical device manufacturing applications by allowing effective material removal with heat-tolerant tools using 4-flute and 2-flute end mills.

Higher speed operation of carbide end mills results in increased production efficiency. Die and mold production applications that use carbide tools achieve quicker processing times with maintained surface uniformity. Coated carbide custom end mills increase tool survival times so manufacturers need to change them less frequently.

General-purpose applications need HSS end mills when considering cost effectiveness as the main factor. These tools have outstanding impact resistance properties which allow their use in situations demanding durability as well as operations with low speeds. HSS imperial end mills serve industries which require flexible machining applications because they retain their value in these situations.

Machining Accuracy and Durability

The selection of custom end mills for industrial applications depends strongly on precise manufacturing together with extended equipment lifespan. The combination of 4 flute end mills and 2 flute end mills provides efficient material removal together with precise dimensional performance and 1 1/4 end mills and 1 1/2 end mills excel in high-performance heavy-duty milling tasks.

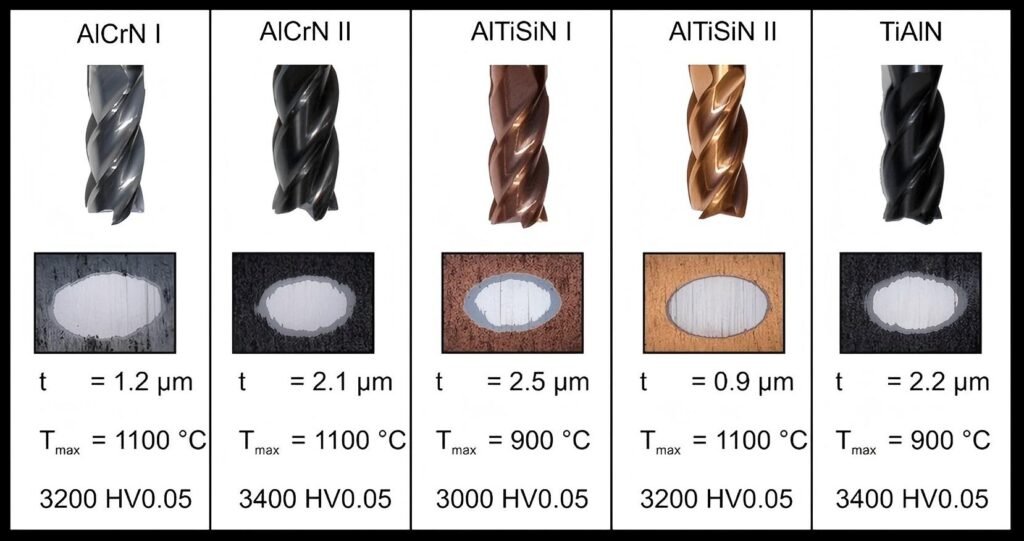

The search for end mills suppliers heavily depends on choosing tools with enhanced durability characteristics. American end mill suppliers need to offer tools with premium coatings between TiN (Titanium Nitride) and TiCN (Titanium Carbo-Nitride) and AlTiN (Aluminum Titanium Nitride). By adding these coatings manufacturers achieve longer tool durability together with decreased friction and improved cutting effectiveness.

Manufacturers need to focus on both tool balancing and edge preparation while making their manufacturing choices. Tools with appropriate balance performance cut down high-speed machining vibrations which in turn results in better finishes and longer tool life. The combination of corner radius together with chamfering features extends tool longevity by protecting it from wear and results in superior cutting efficiency thus making custom end mills an economical choice.

Businesses can make successful decisions about imperial end mills by comprehending these factors to achieve maximum precision and longevity with efficient operation.

Is It Worth Sourcing Imperial Milling Cutters?

When precision and enduring quality and consistent performance are top manufacturing priorities then buying imperial end mills represents an essential business decision. The numerous industrial applications that include automobile manufacturing and mold processing require continued support from high-quality end mill manufacturers operating within the USA territory.

HNCarbide together with other leading manufacturers deliver best metal cutting tools and high-end custom end mills to industrial companies that seek enhanced machining efficiency worldwide. Modern manufacturing depends on imperial end mills because these tools work through standardized sizes together with stringent quality requirements and advanced materials.

Key differences between HSS vs. Carbide End Mills:

Aspect | HSS End Mills | Carbide End Mills |

Material | Made from high-speed steel, offering toughness and durability. | Made from tungsten carbide, providing extreme hardness and wear resistance. |

Cutting Speed | Lower cutting speeds; ideal for general-purpose machining. | Higher cutting speeds; best for high-performance machining. |

Wear Resistance | Moderate resistance; wears out faster in high-heat conditions. | Superior wear resistance; lasts longer even under extreme conditions. |

Cost | More affordable, making it cost-effective for low-volume production. | More expensive but offers long-term savings due to extended tool life. |

Application | Suitable for softer materials like aluminum, mild steel, and plastic. | Best for machining hard materials like stainless steel, titanium, and alloys. |

Heat Resistance | Can soften at high temperatures, reducing cutting efficiency. | Withstands high temperatures, maintaining sharpness for longer. |

Surface Finish | Provides decent surface finish but may require additional finishing passes. | Delivers superior surface finish with minimal need for secondary operations. |

Durability | More flexible, reducing chances of tool breakage. | Brittle compared to HSS but much more durable in terms of edge retention. |

Best Used For | Low-speed, manual, or intermittent machining operations. | High-speed CNC machining and heavy-duty cutting applications. |

DIN Milling Cutters Catalog

Click the button below to view our DIN milling cutters catalog and explore detailed product specifications to make the best choice.

Cost Efficiency and Long-Term Benefits

Welding costs become lower with time when producers invest in high-end end mills. The use of specialized custom end mills leads to superior operational efficiency in combination with decreased equipment maintenance durations along with reduced manufacturing expenses. Manufacturers who work with reputable end mills suppliers achieve regular quality standards as well as precise machining accuracy in their products.

Future Market Outlook

Imperial end mills have an optimistic market outlook since industrial sectors continually increase their need for precise tools. The market will evolve through new developments in best metal cutting tools which will result in products with improved durability and performance capabilities. The competitive edge in a quickly changing manufacturing industry belongs to firms that select better custom end mills.

The enduring presence of imperial end mills in markets stems from their ability to provide precise results and versatile operation supported by meeting worldwide industry standards. Chose reputable end mills suppliers to boost industry productivity while improving manufacturing accuracy for competitive leadership in the marketplace.