How Sample Testing Builds Trust in Choosing Carbide End Mills and Drill Bits

Table of Contents

European purchasers do not make large orders based on spec sheets alone. Things have to be verified in performance before large orders can be approved. Real-world testing will prove how well tools perform on stainless, titanium, and aluminum under actual machining conditions.

Precision, repeatability, and compliance with DIN standards are what German procurement teams are expecting. Surface finish, tool life, and geometric accuracy are all tested as ways to evaluate factors that have an impact on both cost and output.

More manufacturers request trials nowadays to avoid mismatches in tooling and delays in production. With the right sample strategy, suppliers can prove their reliability long before even signing a contract.

The Importance of Sample Testing

Tooling decisions have real production consequences. Catalog specifications may speak to ideal conditions but hardly ever account for the variations discovered across CNC shops. Sample testing fills that gap by verifying how carbide end mills and drill bits perform on the floor.

Engineers and buyers can get some insights into:

- Actual wear behaviour

- Chip evacuation efficiency

- Performance under heat and load

In the machining of stainless steels, titanium, or aluminum alloys, one thing remains is very important, which is durability. Testing exemplifies how a tool handles changes in feed rate, spindle load, and hardness of material being machined.

Results further exemplify how well a tool works across machine types, be it vertical, horizontal, or multi-axis, so teams can make an assured procurement decision based on proof of compatibility.

Testing builds credibility. It allows engineers to measure surface finish quality under real use, to measure vibration levels, and dimensional tolerance in actual operation. Any team that wants to have a strong hand in the go/no-go decision will trust tangible data from controlled testing far more than any marketing claim. This lowers the risk, aids standardisation, and gives a supplier an early chance to prove value before the main rollout.

What Buyers Look for During Testing

Sample testing is about how well tools fit into the production system. European buyers from the automotive, aerospace, and precision engineering industries want technical transparency from suppliers. Every single detail adds up to trust, be it tool geometry, feed rate, or wear pattern.

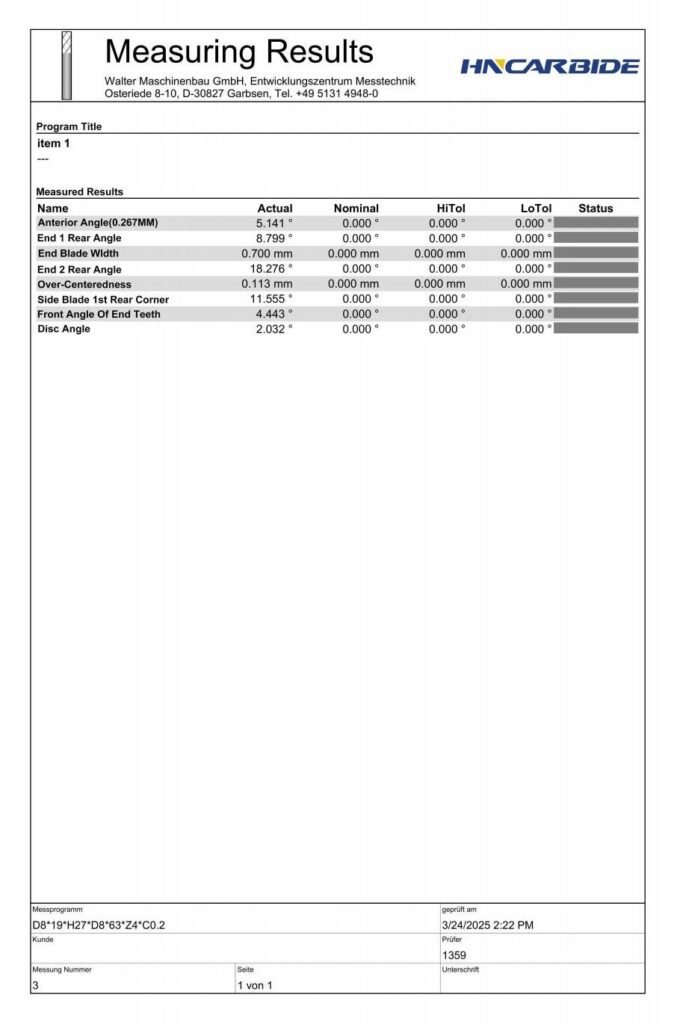

Technical Professionalism in Documentation

Buyers judge the professionalism behind it. Precise documentation reflects how well a supplier understands industrial standards and machining needs. This includes clear, dimensioned drawings, recommended cutting parameters, and expected outcomes based on controlled conditions.

Well-prepared suppliers deliver:

- Detailed CAD drawings of each tool

- Speed, feed, and depth of cut values

- Material compatibility notes and expected tool life

This data enables engineers to conduct controlled experiments and observe tool behavior, as well as compare results between machines. The more accurate the documentation, the fewer variables will cloud the buyer’s evaluation; the more complete it is, the greater will be his confidence in the tool. It serves future orders in good stead and builds up the supplier’s technical reputation.

Surface Finish, Tool Life, and Dimensional Accuracy

European buyers assess the durability of center cutting end mills and 1/2 carbide drill bits under actual use. The surface finish must stay within the set roughness (Ra) for as long as it can be measured in tool life per batch, and how well it keeps cutting to size on every cut.

Roughness, inconsistency of bore diameters, and degradation of tip tools are red flags. Buyers track how long a tool stays sharp and how consistently it meets drawing tolerances, especially in the materials known for their propensity to machine problems.

A technical professional shares actual parameters of cutting speed, feed rate, and geometry, and does not make claims. Buyers seek those suppliers who provide full data packages and drawings so that testing feedback can be substantiated. That is what allows an informed decision to validate that the tool is performing with respect to the intended production goals.

Compliance with Procurement Standards

Procurement teams require traceability and documentation, and are seeking alignment with regulatory frameworks. Carbide tooling must comply with DIN or ISO standards, especially in sectors such as aerospace, medical, and automotive manufacturing.

Buyers often request:

- Material certificates confirming tungsten carbide grade

- Batch inspection reports showing tool tolerance and hardness

- Tool markings with product codes and dimensions for system logging

These details serve as proof that the tools conform to internal quality protocols and are consistent with the existing inventory systems. An unfilled document or a coating specification that has not been verified will postpone a supplier’s onboarding or even cause it to be disqualified. Professional suppliers cannot imagine compliance as something that comes at the end of the process, but rather as part of a tool’s value.

HNCarbide’s Approach

HNCarbide leverages a data-driven sample-based process to provide the technical buyers with the tool they need at the right time for the right price. The batch procedure enables an efficient and fast operation of the small-tool manufacturing. Thus, customers may receive a set of lightweight tools, complete with parts drawings, speed and feed rate settings, and an estimate of the expected tool life.

The team offers post-sample feedback sessions in order to figure out which wear patterns, surface finish troubles, and deviations of tolerance are present. So, buyers can have updated parameters or even be supplied with other tools depending on the test results that they have observed, and turn those short trials into long-term value.

Besides that, the company provides routine professional after-sales support. HNCarbide’s technical staff can help customers to analyse the collected data, adjust the feed rate, and find out if there are any machine-tool mismatches. Running a tool within an optimal performance window is thus guaranteed on each test.

HNCarbide extends its tech assistance to local customers in person and also to remote ones online. Walk-in services for local customers and remote consultations for others facilitate this flexibility. The same flexibility also ensures that teams can continue working without any interruptions while the evaluation phase is going on.

The quality alone cannot satisfy European procurement teams; they also need responsiveness and real-time technical dialogue. HNCarbide is a good match for both needs with open communication, traceable materials, and a sampling model that eliminates risk without hindering production. It’s a hands-on process designed for professionals who crave evidence.

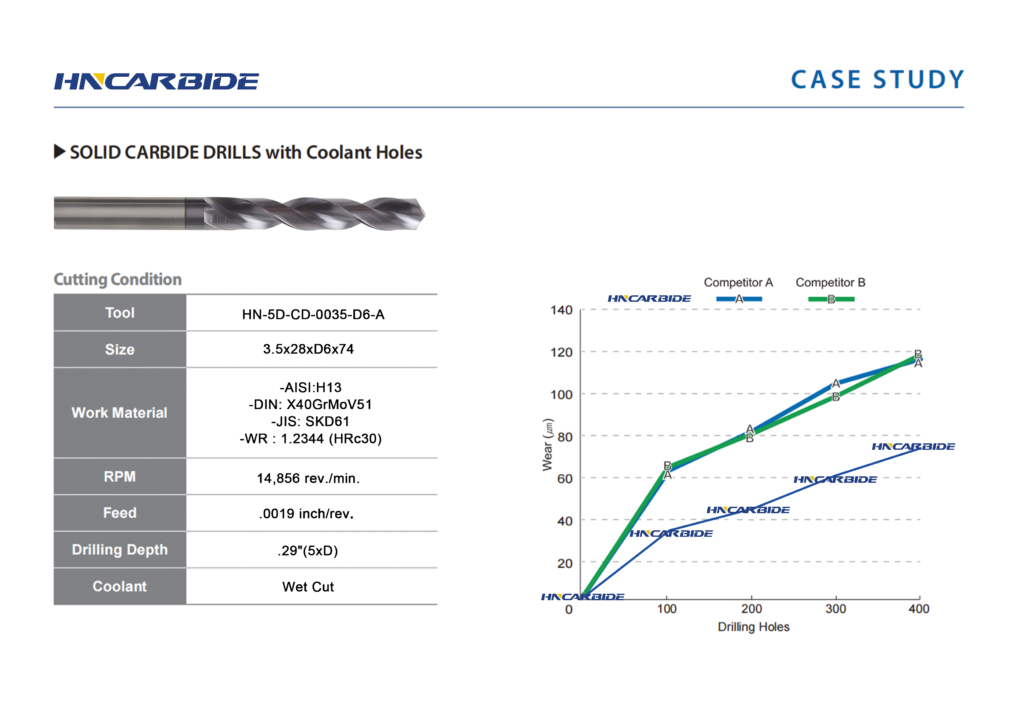

Case Study

A Tier 2 automotive components manufacturer from southern Germany contacted HNCarbide to test a small batch of carbide drill bits for metal that were specifically designed for P20 tool steel and aluminium alloy components. Their aim was to find out how the performance of these drill bits can be compared to that of their current supplier, with a focus on cost reduction and the longest possible tool life.

HNCarbide gave the customers a four flute end mill sample set that contained cutting parameters and compatibility notes. Testing was done on two production lines with the same machine setups and cooling systems. The engineers recorded hole quality, tool wear, and the time of the machining process during a sample run of 500 parts.

Results:

- Machining cost dropped by 15%, driven by faster feed rates and reduced tool change downtime

- Tool life increased by 25%, confirmed through microscope-based wear analysis

- Surface finish improved, maintaining Ra values below 0.8 µm consistently

- No dimensional drift, even at the end of tool life

The company ultimately replaced its mid-tier supplier and signed a longer-term sourcing agreement with HNCarbide. This example shows how hands-on testing with the right technical guidance can lead to lower cost per part and greater consistency in high-volume production.

Beyond the Sample

Sample testing often marks the beginning of a supplier relationship. When performance meets expectations, buyers look for seamless ways to scale procurement. Moving from test batches to ongoing supply requires transparency, documentation, and alignment with internal purchasing protocols. HNCarbide supports this transition through structured processes built for long-term cooperation.

Transitioning from Testing to Long-Term Cooperation

Successful tool testing gives confidence, but repeatability gives trust. Once carbide tools have proven reliable in practice, the next step is to ensure the same conditions are met on a larger scale. HNCarbide assists with production planning, setting appropriate standards, and monitoring the quality of batches to facilitate this process.

Procurement teams value predictability. Every center cutting end mill, chamfer end mill, or 1/2 carbide drill bit delivered must match the performance of the tested sample. HNCarbide keeps records of each batch of tools and the dimensional data to make sure that the tool quality is consistent over repeat orders.

Long-term cooperation also provides logistical benefits. For instance, HNCarbide not only offers volume-based pricing but also buffer stock arrangements and coordinated shipping timelines to reduce delays and inventory pressure. This gives European manufacturers the ability to be more flexible in meeting production goals without the risk of having tool shortages.

Changing the supplier status from trial to trusted means gaining the confidence of every shipment.

Providing Documentation for Procurement Compliance

European buyers expect full traceability. The procurement compliance team may require the origin of the goods, material certificates, and inspection reports as proof. HNCarbide is always ready to supply all the necessary documentation to meet these requirements in any shipment of bulk cargo.

Each delivery includes:

- Certificates of origin

- Material composition reports

- Dimensional inspection sheets

- Batch identification numbers

This paperwork can be used to prove that customs have been complied with and that internal quality audits have been carried out. It also supports buyers in meeting ISO or DIN purchasing requirements, thereby easing supplier access across departments.

Reliable documentation reduces procurement friction and increases confidence that the four flute end mill, chamfer end mill, or 1 2 carbide drill bit you tested is exactly what you’ll receive in every future order. HNCarbide makes compliance part of the process, not an afterthought.

Supporting Customers with Procurement Guidance

Procurement is essentially about adjusting tool supply to align with production needs, timelines, and budget constraints. HNCarbide supports buyers throughout this process by giving hands-on advice that is beyond product specs to simplify it.

The support includes:

- MOQ planning based on forecasted usage

- Batch scheduling tied to part programs or seasonal demand

- Guidance on tool standardisation across teams

Those who are looking for technical insights, such as information on center cutting end mills, four flute end mills, or specialty drills, can get great relief in selection and ordering. In case of a change to their teams, suppliers, or tooling systems, HNCarbide helps with the onboarding process by ensuring machine compatibility and mapping delivery intervals, supporting the teams.

This type of advisory relationship cuts down sourcing risk, leads to shorter lead times, and also helps engineers and purchasing departments stay on the same page. Rather than resolving problems during the process, buyers get support that is more proactive, which allows production to run smoothly from the trial to the reorder.

Technical Data Example

Cutting data in catalogues provides a helpful starting point, but every CNC machine, fixture, and batch of material introduces variables. That’s why sample testing is essential. It allows buyers to confirm that suggested parameters actually deliver the right surface finish, tool life, and part accuracy.

The following table shows cutting speeds and feed per tooth values recommended for end mill machining aluminum and stainless steel. Testing these values in-house helps engineers validate how each tool performs under their unique spindle load, coolant setup, and workholding conditions.

Metric | Aluminum (6061) | Stainless Steel (304) |

Tool Type | Center Cutting End Mill | Four Flute End Mill |

Recommended Speed (m/min) | 250–450 | 60–100 |

Recommended Feed (mm/z) | 0.10–0.18 | 0.03–0.08 |

Surface Finish (Ra µm) | 0.4–0.6 | 0.8–1.2 |

Tool Life (slots or holes) | 1200–1500 | 300–500 |

Adjustment During Testing | Minor (5–10%) | Moderate (10–15%) |

Numbers like these illustrate what engineers typically see during sample testing across CNC shops in Germany. Aluminum can handle much higher feed rates without sacrificing a smooth surface finish. On the contrary, stainless steel requires a more challenging approach, including lower cutting speeds and coatings for heat dissipation and tool life, among other considerations.

This sample-driven data approach enables machinists and the purchasing department to leave behind the reliance on vendor catalogues and better match their production setup with the expected performance of the tool. It further assists them in verifying tool stability, surface finish, and tool life, before taking the step to purchase in bulk

Conclusion

Sample testing gives clear proof of the right tools to be used. It not only checks the performance but also confirms the compatibility of the machines and provides confidence prior to scaling production. The decision to select cutting tools is based on measured results rather than assumptions.

Customers who prioritize testing receive more than just technical confirmation. They obtain a reliable process. Along with tool life, surface finish, and accuracy, it is possible to make changes to ensure the smoothest rollout of the scheme and avoid surprises on the shop floor.

Request a sample from HNCarbide today and experience precision that earns long-term trust, not just short-term output.