How High Feed Milling Inserts Maximise Efficiency in Modern CNC Machining

Table of Contents

High feed milling has become the go-to strategy for CNC shops that have a need for more parts out of the door in record time. This process is used by industries such as aerospace, automotive, and mould making because material removal is much faster without straining machines or tooling to the maximum limits.

At the centre of this shift are high feed milling inserts. They use a shallow depth of cut but run with a much higher feed per tooth than traditional tools, allowing them to remove metal at great rates while maintaining very low cutting forces. Cycle times become even shorter, reducing vibration and providing a more consistent finish on hardened steels, stainless steel, or high-temperature alloys.

Shops that need to make fast deliveries without quality loss are seeing high feed milling inserts as a real way to raise output and gain cost-efficiency.

Understanding High Feed Milling

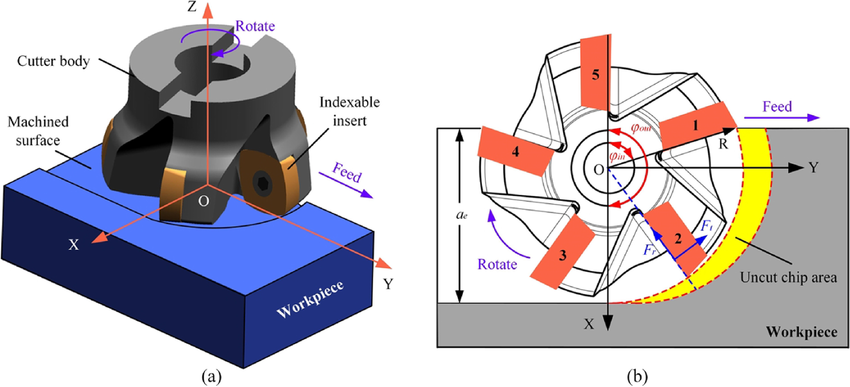

High feed milling is the type of milling that uses a shallow depth of cut with high feed per tooth to easily attain fast metal removal while maintaining good stability. In this method, cutting forces are directed axially, which reduces tool deflection and increases productivity.

Compared to conventional milling, it is based on speed and controlled engagement rather than on deep material removal in one pass. It is best suited for industries where throughput and consistent performance are major concerns.

High feed milling cutters are used across:

- Aerospace components: lightweight alloys, structural parts, and precision fittings

- Mould and die cavities: roughing hardened tool steels with minimal vibration

- Automotive components: engine blocks, transmission housings, and chassis parts

- Energy-sector parts: stainless steel turbine elements and high-strength alloy fittings

These applications explain how this method accommodates different materials and industries. This makes it practical when choosing between achieving productivity and reliable machining results.

Advantages of High Feed Milling Inserts

High feed milling inserts introduce tangible enhancements to CNC operations through speed, stability, and cost-effectiveness in the long run. The benefits accruing from their performance are more pronounced in production environments, wherein every minute saved has a bearing on the overall profitability.

Substantial Reduction in Machining Time

High feed milling cutters are engineered to remove material quickly without compromising stability. The insert geometry allows more feed per tooth than it does with traditional milling methods. More material is removed in a shorter time, resulting in significant time savings per component, particularly in large-scale production or when a project is under a tight delivery schedule.

When multiplied over hundreds or thousands of parts, it will add up to reducing machine time for other work that has to be performed, and this is very attractive in situations where throughput has a direct bearing on competitiveness, such as in the automotive, aerospace, or heavy equipment industries.

Lower Cutting Forces and Less Tool Deflection

The biggest challenge in machining is controlling cutting forces. If not properly controlled, it may lead to deflection, chatter or poor surface finish. High feed milling inserts attempt to solve the problem by employing a shallow depth of cut, aided by optimised edge geometry, which results in a chip-thinning effect. This subsequently means the cutting edge is not subject to the same force as before, and the workpiece also experiences lower force. Hence, the spindle and tooling receive less stress.

Smaller deflection means that parts can still be within a tighter tolerance range, even if the components are taller or slender, which are more vulnerable to vibration. This stability is vital in guaranteeing that repeatable quality is achieved in shops that are carrying out carbide insert end mill high speed operations.

Over time, the mechanical stress reduction leads to the prolonging of both tool and machine life, while the maintenance cost goes down, and the production remains consistent and predictable throughout the process.

Improved Productivity in Tough Materials

Working with hardened steels, stainless steel, or high-temperature alloys typically calls for slower feeds and speeds in order to avoid rapid tool wear. High feed milling inserts that are outfitted with coated carbide inserts, like AlTiN or TiCN, are able to endure harsh cutting situations even in these hard materials.

The immutable velocity of the cutting passes, the rapid rate of feed, and the efficient coating work in harmony to suppress the heat generated at the cutting edge. In addition, it serves as a shield to the cutting edge. Consequently, shops can operate at higher metal removal rates while not having to worry about the tool being worn out prematurely.

The level of flexibility these inserts can offer to a company gives it a leading edge over its competitors in a production set-up where the hardness of the materials can change from time to time. In particular, this is true for the aerospace, mould-making, and energy sectors where the part materials are normally hard, but the throughput requirement is very high.

Insert Design Features

High feed milling inserts take their performance advantages from precise engineering. Each design element is a part that fits and works to control the chip formation, heat, and the cost of the energy. These characteristics guarantee stable and reliable results across very harsh CNC applications in Germany’s automotive, aerospace, and heavy machinery sectors.

Unique Edge Geometry for Chip Thinning

High feed milling inserts are constructed with edge profiles that make chips thinner and more easily handled during the cutting process. This chip-thinning effect not only cools the cutting area but also reduces the amount of heat generated and alleviates friction both on the insert and the workpiece. Lower cutting forces also mean less vibration, which helps maintain dimensional accuracy and extends tool life.

When paired with high feed milling cutters, this geometry allows for faster feed rates without compromising surface finish. The consistent chip shape improves evacuation, preventing built-up edges and reducing the risk of tool failure. The design ensures stable performance across long production runs while supporting higher throughput in demanding operations such as machining hardened steels or titanium alloys.

Multi-Edge Capability for Cost Efficiency

High feed milling inserts often feature multiple cutting edges, allowing the tool to be rotated or indexed to a fresh edge when one becomes worn. This significantly extends the insert’s usable life and reduces the frequency of replacements. The result is lower tooling costs over time and better resource utilisation for CNC operations.

Multi-edge designs also help maintain consistent performance across cycles, as each new edge offers the same geometry and cutting quality. This predictability is essential in high-volume production, where downtime from tool changes can quickly add up.

Heat-Resistant Coatings for Extended Life

High feed milling inserts are frequently coated with modern materials that greatly aid in heat dissipation during very aggressive cutting. Coatings like AlTiN (Aluminium Titanium Nitride) and TiCN (Titanium Carbonitride) reduce the heat generated at the cutting surface, offer thermal protection, oxidation prevention, and impede the creation of a built-up edge.

Besides these protective measures, the cutting temperature is also kept in control, which is especially important in the case of machining of hardened steels, stainless steel, and heat-resistant alloys, where the cutting temperature rises abruptly.

Comparison of Common Heat-Resistant Coatings

Feature / Property | AlTiN Coating | TiCN Coating |

Oxidation Resistance | Excellent at high temperatures | Good, but less than AlTiN |

Wear Resistance | High | Very high in abrasive conditions |

Best Use Materials | Hardened steel, stainless steel, heat-resistant alloys | Cast iron, non-ferrous metals, abrasive composites |

Ideal Cutting Conditions | Dry or minimal coolant | Wet machining preferred |

Heat Management | Exceptional thermal barrier | Moderate thermal protection |

Practical Application Examples

Real-world data proves theory, and high feed milling delivers. Case studies and machining trials have been conducted, consistently showing that cycle time reductions of 30% to 50% can be achieved compared to conventional milling, even for hard materials such as tool steels and Inconel.

Wear analysis points out that the tool life is the main issue that can be addressed if forces and temperature are kept under control. In the case where edge wear is approximately 0.3 mm, the tool life curve clearly shows that insert performance is continuously decreasing, which can be best addressed by selecting a suitable geometry and coatings.

Here’s how this plays out in testing:

- Cycle time reduction:High feed inserts cut machining times by up to 30%, improving throughput on critical parts.

- Wear pattern observations:Flank wear tends to remain steady until failure thresholds are reached. Testing helps catch wear before surface quality suffers.

- Sample policy:HNCarbide offers initial sample inserts for under $10, allowing shops to test performance firsthand without a major investment.

Such cases illustrate how high-feed milling inserts can revolutionise production speed and tool life, two essential components for precision-focused CNC operations in Germany.

Choosing the Right Holder and Setup

Choosing the proper holder and configuration bears the same weight as the quality of the high feed milling cutters themselves. The best carbide inserts, if installed in a holder that is not stable or compatible, can give a less-than-optimal performance. A compatible indexable holder not only allows the insert and the workpiece to have the best engagement but also reduces the vibration and keeps the chip load constant. The clamping stability directly affects the surface finish, tool life, and the overall machining accuracy.

Stores that spend time matching their carbide insert end mill high speed setups with the right holder geometry are frequently able to demonstrate gains in productivity. Such a method not only ensures the advantages of high feed milling speeds and feeds but also avoids insert wear or failure caused by the wrong decision.

Compatibility With Indexable Holders

High feed milling inserts require compatibility with holders to ensure the insert seats as designed, follows the intended cutting path, and maintains consistent chip evacuation. Any mismatched holders will allow the possibility of micro-movement during operation- this results in chatter and uneven wear that reduces tool life.

Choose indexable holders made by good brands that follow DIN and ISO rules to keep strength at high speeds and feeds for milling. This match between insert and holder is very important to get exact limits and make the life of both the insert and holder longer in areas like aerospace, mould making, and car work.

Tips on Clamping Stability To Avoid Vibration

High feed milling cutters allow for high feed rates, so even a small lack of stability can result in vibration that then affects the surface finish, dimensional accuracy, and tool life. Clamping stability starts with a sturdy machine setup and goes to every part in the toolholding chain.

The use of precision-balanced holders not only prevents the risk of imbalance at high spindle speeds but also ensures that the insert pocket is clean, which stops micro-gaps that are the main sources of chatter.

Reducing the tool overhangs increases the rigidity of the tool significantly, especially in the case of machining hardened steels or stainless steel, where the cutting forces are higher. Applying the right torque while tightening the screws or the clamping mechanism guarantees the pressure to be uniform without any distortion of the insert seat.

Checking the holder and the parts for clamping continuously is also very important. Problems like worn clamping screws, damaged seats, or a lack of a proper locking system, all of which can lead to the loss of stability, need to be dealt with. In aerospace and die mould manufacturing, sectors known for having very tight tolerances and materials that are difficult to work with, stable clamping is non-negotiable.

Last but not least, utilising coated carbide inserts together with holders that are specifically designed for high feed milling facilitates the optimal cutting conditions. This combination leads to minimisation of vibration, reduced heat generation, and steady chip formation, resulting in increased productivity and tool life in demanding CNC environments.

Feed and Speed Recommendations

When high feed milling end mill speeds and feeds are selected correctly, it can lead to the longest tool life and the most stable machining results. These parameters must be customised for the insert’s shape, coating, material of the workpiece, and the machine’s rigidity. High feed milling’s very shallow depth of cut is the reason why much higher feed per tooth values are allowed than in conventional milling, although the limit should not be exceeded for faster wear or insert chipping.

Typical suggestions for assigning spindle speed and feed:

- Start with manufacturer-recommended parameters for the specificcarbide insert end mill high speed

- Feed per tooth should be increased stepwise, while surface finish and spindle load are being observed.

- Cutting speed should be lowered for heat-sensitive alloys or hardened steels.

- Machining aluminium with uncoated or polished-edge inserts should always be done at high speeds.

- Besides ensuring the thermal stability of the tool with adequate coolant flow, make sure that the coolant also flushes the chips efficiently.

These parameter adjustments help fine-tune the performance for the actual machine and setup. Hence, many coated carbide inserts are able to deliver their best performance if they remain within the optimal temperature range.

Conclusion

High feed milling cutters are dependable for accomplishing faster throughput and saving on machining costs for various challenging applications. Their special shapes, multiple edges, and heat-resistant coatings are a necessity for those manufacturers who are planning to make the most of cycle times without losing accuracy or tool life.

Numerous CNC shops in Germany are extensively utilising these inserts to increase performance in hardened steels, stainless steel, and high-strength alloys, thus proving that the proper tooling can provide a measurable return on investment (ROI) in modern production lines.

HNCarbide offers technical data, application support, and free samples under $10 to help buyers validate performance before full-scale adoption. Contact our team today to discuss your requirements, review test results, and request a sample to see the benefits firsthand.