How Does Helix Angle Really Affect Solid Carbide End Mill Performance?

Table of Contents

When selecting a solid carbide end mill, many users focus on coating, flute count, or diameter. But there is one geometric parameter that often decides whether a tool runs smoothly or chatters itself to failure:

The helix angle.

Why do some end mills cut quietly while others vibrate under the same conditions?

Why do high-helix tools excel in aluminum but struggle in heavy roughing?

And how should engineers really choose helix angles for steel, stainless steel, or composites?

This article answers those questions from a cutting mechanics and product design perspective, not marketing slogans.

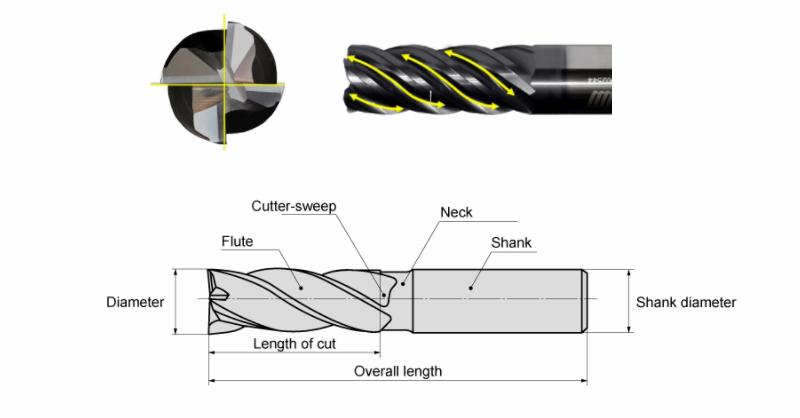

What Exactly Is the Helix Angle of an End Mill?

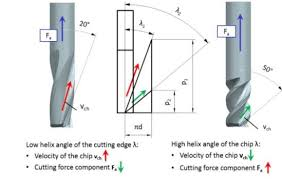

The helix angle (β) is defined as the angle between the tangent of the helical cutting edge and the axis of the end mill.

From cutting theory, the helix angle at the outer diameter is equivalent to the tool’s axial rake angle.

This means the helix angle does far more than shape the flute—it directly controls:

- Direction and magnitude of cutting forces

- Tool stiffness utilization

- Chip flow behavior

- Vibration resistance

- Heat generation and evacuation

In short, helix angle determines how “friendly” the cutting process is.

Why Do Straight Flute End Mills Vibrate So Easily?

Let’s start with the extreme case.

Straight flute end mills (β = 0°):

- Axial rake angle ≈ 0

- Axial cutting force ≈ 0

- Nearly 100% of cutting force acts radially

This is a problem because:

- The radial direction is the weakest stiffness directionof an end mill

- Any fluctuation in cutting force directly excites vibration

- Chips flow sideways and often re-enter the cutting zone

- Secondary cutting increases heat and accelerates wear

Result:

Straight flute tools are extremely sensitive to chatter and are rarely suitable for modern high-efficiency machining.

How Do Helical Flutes Improve Stability and Chip Evacuation?

Once the helix angle increases above zero, everything changes.

Helical flute end mills:

- Cutting force splits into radial + axial components

- A portion of force is redirected along the tool axis

- The axial direction has the highest tool stiffness

- Radial load per tooth is reduced

- Chips are guided smoothly out of the cutting zone

This is why almost all modern solid carbide end mills use helical flutes.

But how much helix is enough—and when is too much?

Does a Larger Helix Angle Always Mean Better Performance?

Not necessarily.

To understand why, we need to look at engaged cutting edge length.

How Do Flute Count and Helix Angle Work Together?

When an end mill cuts, only part of each flute is engaged. What matters is the total axial projection of all engaged cutting edges.

Example Cutting Conditions:

- Tool diameter: Ø10 mm

- Radial depth of cut (ae): 10 mm

- Axial depth of cut (ap): 15 mm

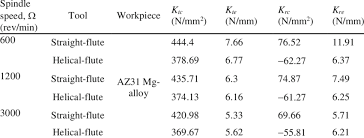

Tool Geometry | Helix Angle | Flutes | Axial Projection of Total Engaged Edge |

Solid carbide end mill | 30° | 2 | ~17 mm |

Solid carbide end mill | 30° | 3 | ~25 mm |

Solid carbide end mill | 30° | 4 | ~30 mm |

High-helix end mill | 60° | 6 | ~47 mm |

What Does This Tell Us?

As helix angle and flute count increase:

1.More cutting edges are engaged simultaneously

2.Total effective cutting edge length increases

3.Load per unit edge length decreases

4.Cutting becomes smoother and more stable

This is why high-helix, multi-flute tools excel in finishing and light-to-medium cutting loads.

So Why Aren’t All End Mills Made with 60° Helix Angles?

Because higher helix angles also introduce trade-offs.

What Are the Downsides of High Helix Angles?

Aspect | Low Helix (20°–30°) | Medium Helix (35°–45°) | High Helix (50°–60°) |

Radial force | Higher | Balanced | Low |

Axial force | Low | Medium | High |

Tool core strength | Strong | Balanced | Reduced |

Chip evacuation | Average | Good | Excellent |

Best use | Heavy roughing | General purpose | Finishing / aluminum |

High helix tools:

- Generate larger axial forces

- Require strong tool holding and machine rigidity

- Have smaller core diameter, reducing torsional strength

That’s why roughing tools for steel often stay around 30°–35°, while aluminum tools go up to 55°–60°.

How Does Helix Angle Affect Different Workpiece Materials?

Steel and Alloy Steel

- Recommended helix: 30°–35°

- Balanced cutting forces

- Strong core for shock resistance

- Suitable for slotting and roughing

Stainless Steel

- Recommended helix: 35°–45°

- Reduces work hardening

- Improves surface finish

- Stabilizes cutting under high friction

Aluminum and Non-Ferrous Metals

- Recommended helix: 45°–60°

- Maximizes chip evacuation

- Prevents built-up edge

- Enables high feed rates

Hardened Materials

- Recommended helix: 40°–50°

- Smooth cutting action

- Lower vibration during finishing passes

How Do Cutting Direction and Helix Direction Interact?

Once the machine spindle direction is fixed, the helix direction determines the axial force direction.

Typical configuration:

- Right-hand helix + right-hand cutting

- Chips are pulled upward

- Suitable for most metal machining applications

However, in thin-walled parts or layered materials, axial force direction becomes critical.

Why Are Double Helix End Mills Essential for Composite Materials?

Composite materials such as CFRP or GFRP behave very differently from metals. They are layered, anisotropic, and prone to delamination.

Double helix (compression) end mills solve this by:

- Combining up-cut and down-cut helices

- Generating downward pressure at the top layer

- Neutralizing axial forces at the center

- Preventing fiber pull-out and delamination

Key advantages:

- Clean edges on both top and bottom surfaces

- Large chip space for abrasive dust

- Reduced cutting heat

- Pure shearing of fibers instead of tearing

These tools are indispensable for aerospace and automotive composite machining.

How Should Engineers Choose Helix Angle in Real Production?

Here is a practical selection guide used by many tool manufacturers:

Application | Recommended Helix Angle | Typical Tool Design |

Heavy steel roughing | 30° | 4-flute, strong core |

General-purpose machining | 35°–40° | 4–5 flutes |

Stainless steel | 40°–45° | Unequal flute spacing |

Aluminum machining | 50°–60° | 2–3 flutes, polished flutes |

High-precision finishing | 45°–50° | Multi-flute |

Composite materials | Double helix | Compression type |

Final Thoughts: Why Helix Angle Deserves More Attention

The helix angle is not a minor detail—it is a core design parameter that defines how an end mill behaves under load.

Choosing the right helix angle:

- Improves stability

- Extends tool life

- Increases machining efficiency

- Reduces scrap and rework

For manufacturers of solid carbide end mills, helix angle selection is where geometry, material science, and real-world machining experience truly intersect.