Deep Hole Drilling: Challenges, Solutions, and the Role of Advanced 3D/5D Drills

Table of Contents

Introduction

Deep hole drilling is one of the most challenging areas in machining, especially when the depth-to-diameter ratio exceeds 8:1. Although no strict global standard defines a “deep hole,” machinists commonly use this ratio as a benchmark. For example, drilling a 2.4 mm hole with a depth of 115 mm yields a ratio close to 48:1—an operation that places enormous demands on tools, machines, and processes. Such extreme dimensions amplify problems related to chip evacuation, heat generation, tool stability, and hole accuracy.

This article explores the critical factors influencing deep hole machining: workpiece material, tool materials, geometry, coolant strategies, and cost efficiency. It also introduces HNCarbide’s 3D/5D internal- and external-coolant drills, designed to provide stable, high-quality performance in precisely these challenging applications.

Workpiece Material Considerations

One of the first variables in deep hole drilling is the workpiece itself. Simply describing the material as “steel” or “cast iron” is insufficient.

Steels vary widely: from low-carbon steels that are relatively soft and forgiving, to medium-carbon and alloy steels that harden significantly during machining. Heat treatment also plays a crucial role, making some grades extremely tough to drill without rapid tool wear.

Cast steels and cast irons present another challenge. Defects such as porosity and hard inclusions (often sand or carbides) can interrupt drilling and damage tools.

Accurately specifying the grade and hardness of the material is essential. This allows the selection of an appropriate drill design, geometry, and coating to maximize tool life and maintain dimensional accuracy.

Tool Materials: HSS vs. Carbide

Traditionally, many workshops rely on high-speed steel (HSS) drills for deep hole machining, often using a peck-drilling strategy: advance slightly, retract to evacuate chips, and repeat.

Feature | HSS Drill | Solid Carbide Drill |

Cost | Low (<$30) | Higher (custom often >$100) |

Tool Life | Short, requires frequent regrinding | Long, wear-resistant |

Efficiency | Low, requires pecking | High, continuous drilling |

Depth Capability | Up to ~8–12×D | Up to 30–50×D with coolant |

Surface Finish | Fair | Excellent |

Best Use | Low-cost, low-volume jobs | Precision, high-volume or hard materials |

By contrast, carbide drills are often the only viable solution when hole ratios exceed 15:1.

Hole Quality Requirements

The definition of “quality” in hole drilling is not always straightforward. Depending on the application, the priorities may differ:

Dimensional tolerance – meeting diameter specifications.

Surface finish – ensuring smooth walls free of scratches or feed marks.

Concentricity and straightness – preventing deviation along the depth.

In high-value industries such as aerospace or automotive, hole quality directly impacts part performance. Excessive heat during drilling, for instance, can cause work hardening, making subsequent tapping or reaming nearly impossible.

In low-volume jobs (e.g., drilling only two holes), machinists may prioritize surface finish and accuracy over speed. In high-volume production (hundreds of holes), efficiency and cycle time often take precedence.

Drill Geometry and Coating Design

The geometry of the drill is fundamental to deep hole performance. Key elements include:

Helix angle:

Low helix (20–30°) is effective for brittle, short-chipping materials such as cast iron.

High helix (>35°) is preferred for ductile materials like aluminum or copper, where chip evacuation is critical.

Margins:

Single-margin drills minimize contact and are ideal for long-chipping materials like stainless steel.

Double-margin drills stabilize the tool, guiding it in deep holes and leaving smoother finishes—especially in short-chipping materials.

Web thickness and chisel edge: Proper balance prevents excessive thrust force and reduces deviation during entry.

Coatings also play a decisive role. Advanced multi-layer coatings (e.g., TiAlN with silicon-enriched layers) provide high lubricity, reduce built-up edge formation, and withstand cutting temperatures above 1000°C. Such coatings extend tool life, particularly in high-speed drilling applications.

Coolant Management in Deep Hole Drilling

Coolant is as important as the tool itself in deep hole operations.

Internal coolant delivery provides pressurized flow directly to the cutting edge, ensuring effective chip evacuation and heat dissipation.

External coolant may suffice for shallow or less demanding holes, but is usually inadequate for ratios beyond 8:1.

Coolant concentration and filtration are also critical: optimal mixture increases lubricity, while fine filtration prevents chip recirculation and clogging of through-holes.

Proper chip control ensures that the chips form short, shiny curls. Dull, tangled chips can scratch the bore surface, increase friction, and accelerate tool wear.

Cost Analysis and Efficiency

Many shops focus heavily on the upfront cost of drills, neglecting the larger picture of total machining cost. A typical breakdown looks like this:

Tooling: 3%

Machining time: 30%

Downtime: 7%

Coolant: 16%

Tool changes: 25%

Other overhead: 19%

Although carbide drills are more expensive, they reduce cycle time, minimize tool changes, and improve hole quality—significantly lowering total costs in volume production.

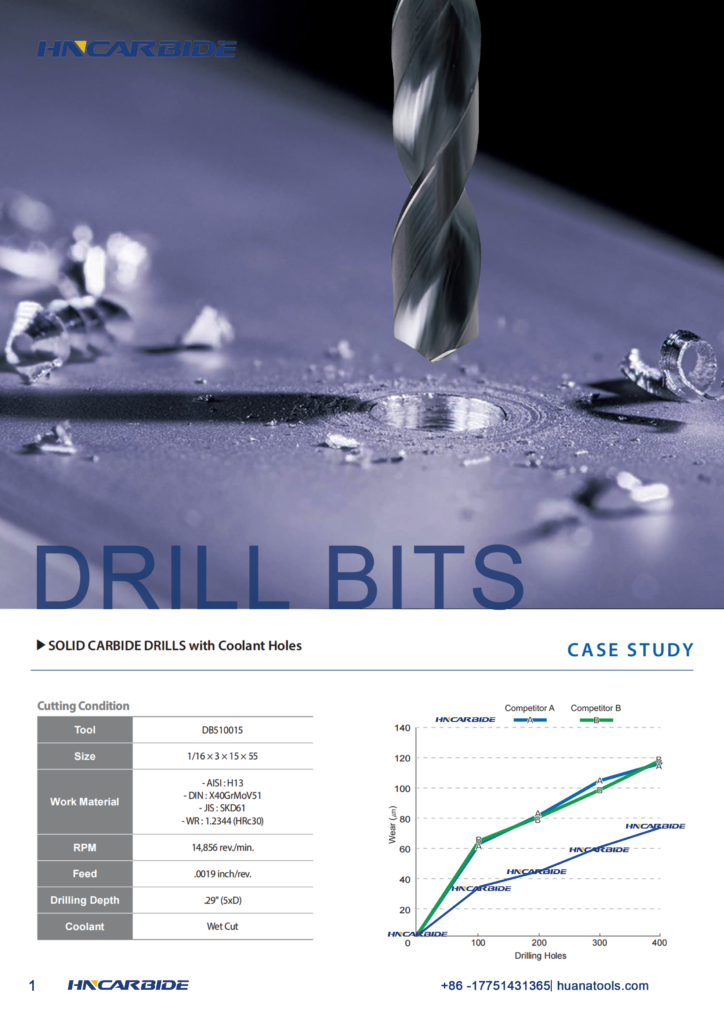

Drill Bit Product

Catalog

Click the button below to view our DIN milling cutters catalog and explore detailed product specifications to make the best choice.

HNCarbide 3D/5D Drill Solutions

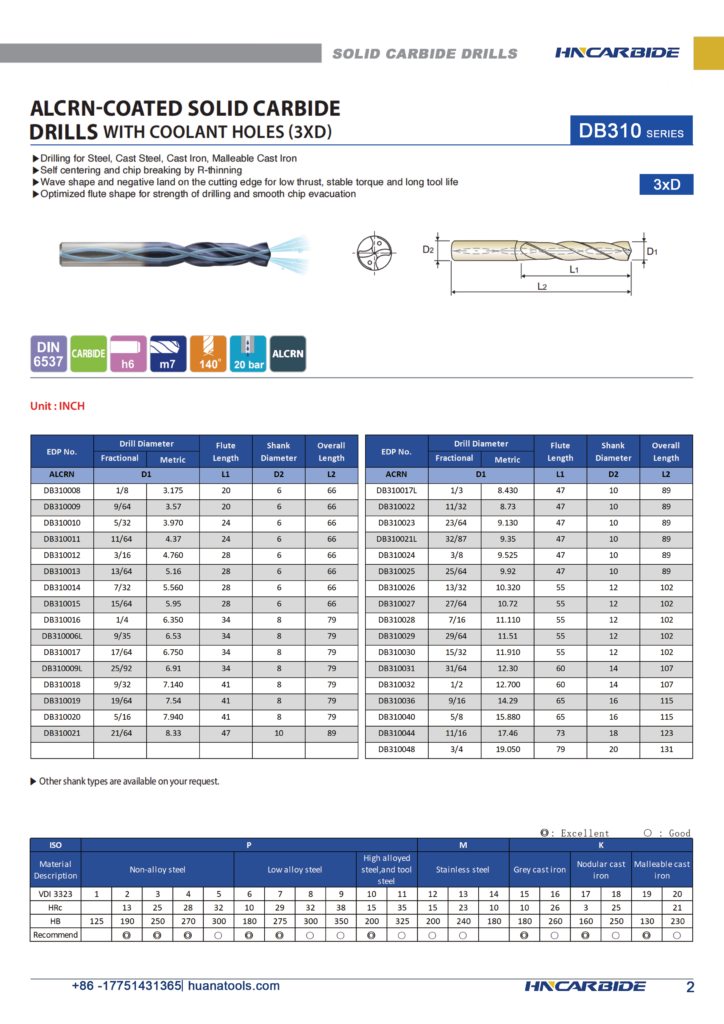

To address the demands of modern machining, HNCarbide offers advanced 3D and 5D solid carbide drills with both internal- and external-coolant options.

Parameter | Specification |

Substrate | Ultrafine-grain WC-Co carbide (0.6 µm) |

Helix Angle | 30–40° |

Diameter Range | Ø3–Ø20 mm |

Lengths | 3×D and 5×D |

Coolant Channels | Dual internal coolant holes (up to 80 bar) |

Coating | TiAlN + Si-based nanolayer, oxidation resistant to >1200°C |

Advantages:

Superior tool life compared to HSS and standard carbide drills.

Stable chip evacuation in deep holes.

Excellent surface finish and dimensional accuracy.

Reduced cycle time and lower overall machining cost.

Applications:

Automotive engine blocks and transmission housings.

Aerospace structural parts requiring tight tolerances.

Mold and die manufacturing for precision holes.

By combining robust substrate materials, optimized geometry, and advanced coatings, HNCarbide drills provide reliable performance in operations where failure is not an option.

Conclusion

Deep hole drilling is a complex process shaped by many interacting factors: material properties, tool design, coolant management, and economic considerations. While HSS drills may suffice for low-cost, shallow jobs, carbide tools are indispensable for demanding applications.

Choosing the right tool is not just about purchase price—it is about ensuring consistent performance, reducing downtime, and delivering the required hole quality.

With its 3D/5D internal- and external-coolant drills, HNCarbide provides a proven solution for manufacturers seeking both precision and productivity in deep hole machining. These drills represent not just a tool, but a complete approach to efficiency, reliability, and long-term cost savings.