Choosing the Right DIN Standard Drill Bits for Precision Manufacturing

Table of Contents

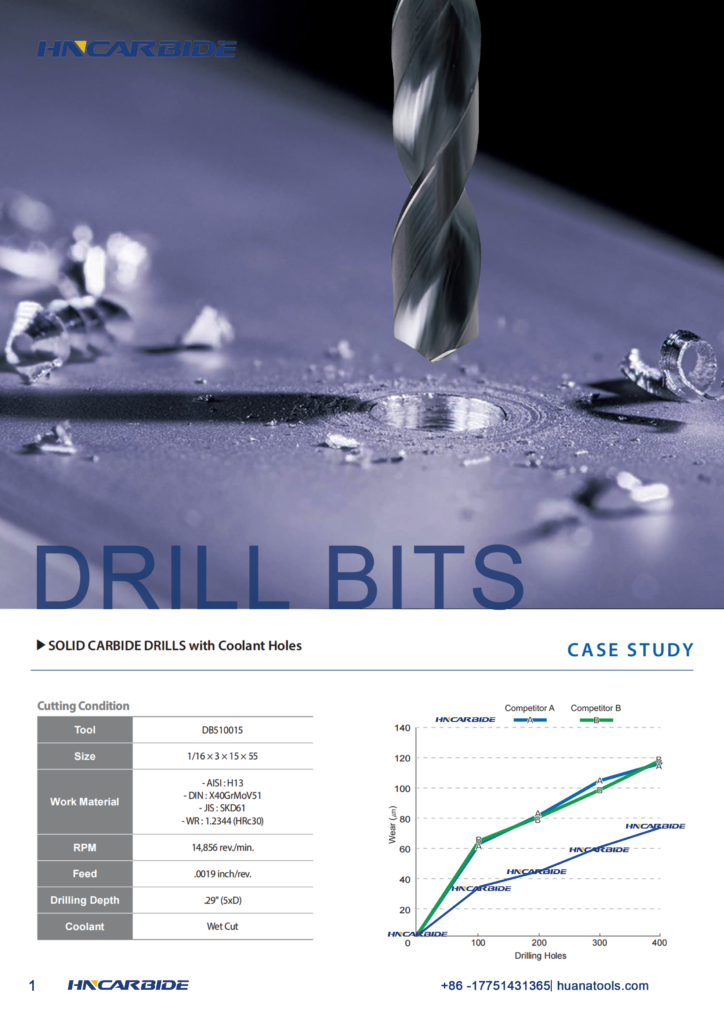

Precision in CNC manufacturing depends on every stage of the process, and drilling is one of the most critical. Even with advanced machining centres, poor drill bit performance can lead to tolerance issues, surface defects, and costly downtime.

German high-precision industries, which include aerospace, automotive, and medical manufacturing, consistently adopt DIN standard drill bits so as to ensure quality remains on a repeatable level.

One misdrilled hole can throw off alignment, reduce structural strength, and ruin an entire production run. Choosing the right DIN-standard drill bit involves matching the tool’s abilities to what the material needs, how it will be used, and what checks must be done to keep up long-term performance and reliability.

Common DIN Standards Explained

DIN standards provide a uniform structure concerning the dimensions, tolerances, and performance characteristics of drill bits so that tools can satisfy the demanding requirements for precision manufacturing.

Different DIN numbers relate to different geometries and uses of drills. Some common standards include:

DIN Standard | Description | Application |

DIN 338 | Straight shank twist drills, jobber length | General-purpose drilling in steel, aluminium, and plastics |

DIN 340 | Long series twist drills | Deep hole drilling in softer metals and plastics |

DIN 1897 | Short length twist drills | High-rigidity drilling in sheet metal and thin materials |

DIN 1869 | Core drills | Pre-drilling before reaming or boring |

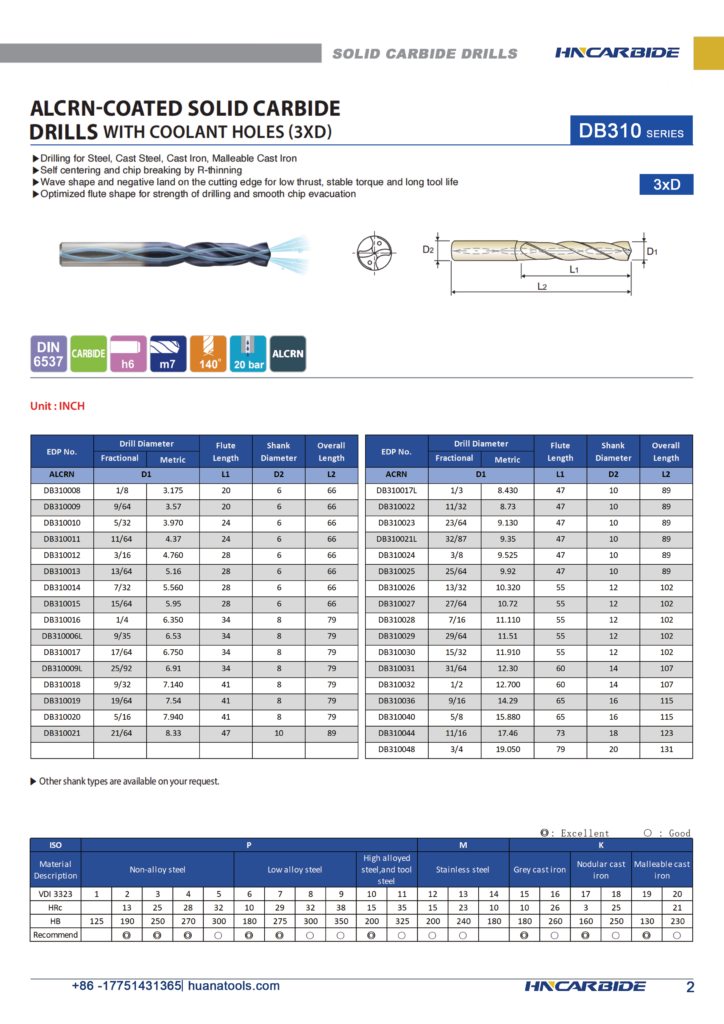

DIN 6537 | Solid carbide drills, short and long types | High-speed drilling in hardened steel and alloys |

Material and Coating Options

Selection of the proper drill bit material is critical to achieving the performance and cost objectives of precision manufacturing. DIN-standard drill bits come in a variety of materials engineered for specific applications.

Carbide for Hard Metals

Solid carbide drill bits continue to be preferred where the job requires maximum hardness, rigidity, and wear resistance. Made from fine-grain or ultra-fine-grain tungsten carbide, these tools perform drilling operations on hardened steels, titanium alloys, nickel-based superalloys, and other high-strength materials.

Carbide can maintain the sharpness of its edge at very high spindle speeds without getting deformed by heat. This translates to reduced cycle times, minimal tool changes, and consistent bore quality even at aggressive feed rates.

Carbide drill bits, a product of tools that come with advanced coatings such as AlCrN or TiAlN work well under dry or semi-dry conditions and hence eliminate the requirement of flood coolant in most setups.

Carbide tools may be more expensive than HSS variants upfront, but due to their durability and predictable performance, the cost per hole becomes lower when using them in high-volume production runs.

HSS with Cobalt for Stainless Steel

High-speed steel cobalt drill bits were intended for use on work-hardening materials such as stainless steel, Inconel, and certain tool steels. The addition of cobalt increases hot hardness, the ability to maintain its hardness at elevated cutting temperatures, thus increasing wear resistance and retaining a sharp edge.

Cobalt HSS drills are well known for their toughness and performance in cutting for manufacturers who are drilling stainless steel in DIN-compliant production environments. The drills provide more resilience against chipping and breakage in manual machines because they are more flexible and are suitable for older CNCs or applications where there is a possibility of vibration.

In combination with a TiN or TiAlN coating, cobalt HSS drills can go a long way in increasing tool life, thus resulting in fewer interruptions from regrinding or replacing tools. This makes them the dependable option for either medium-volume production runs or where part geometry presents the need for flexible feed and speed adjustments.

Coating Comparison

Deciding on the right coating can be of equal importance as choosing the base material for a DIN standard drill bit. Coatings directly influence parameters such as the temperature of cutting, the evacuation of chips, the tool life, and the surface finish quality.

Coatings like TiN, TiAlN, and AlCrN compete for the choice of a precision CNC manufacturing platform, each one having distinct advantages. The correct decision relies on the machining material, speeds of operation, and expected conditions during the process.

Property | TiN (Titanium Nitride) | TiAlN (Titanium Aluminium Nitride) | AlCrN (Aluminium Chromium Nitride |

Properties | Low friction, moderate hardness, gold finish | High oxidation resistance, retains hardness at elevated temperatures | Exceptional heat resistance, high wear protection |

Best Applications | General-purpose drilling in steel, aluminium, plastics | Hardened steels, stainless steel, high-speed dry/wet cutting | Heat-resistant alloys, aerospace materials, dry machining |

Relative Tool Life | Medium | High | Very High |

Heat Resistance | Up to 600 °C | Up to 800 °C | Up to 1,100 °C |

Surface Finish Quality | Good in softer materials | Excellent for harder metals | Excellent in high-temp environments |

The utmost efficiency and prolonged tool life can be achieved when the coating selected is matched with the workpiece material. Steel drill bits are best served with TiAlN, while stainless steel drill bits would benefit the most from AlCrN.

Furthermore, a 6mm drill bit will have a longer life span, and the holes will be cleaner if a proper coating is applied. In short, coating selection is an imperative step in the process of precision manufacturing.

Application-Based Recommendations

Choosing a DIN standard drill bit that is appropriate for the application involves more than just finding one with a diameter that matches the drawing. A large part of productivity in manufacturing is finding a tool whose substrate, geometry, and finish are compatible with the requirements of the application.

A drill bit designed for aluminium will not be at its best in heat-resistant alloys, and a coating that is suitable for stainless steel might be too much for materials that are softer.

Aerospace

Drilling aerospace-grade materials such as Inconel, titanium, and heat-treated stainless steels requires tooling that can handle extreme thermal and mechanical stress.

These alloys:

- Generate high cutting temperatures

- Resist deformation under load

- Rapidly wear down standard drill bits

DIN-standard carbide drill bits are good on this occasion. Moreover, those drill bits with AlCrN or TiAlN are even better. Both of these coatings have high heat resistance and maintain their hardness even under harsh conditions.

Optimised drill geometries enable operations without the work hardening effect, improve chip evacuation, and keep the hole quality consistent

In aerospace manufacturing, the tolerated deviations are as small as microns, so there is no place for a dimensional error. Choosing the best combination of material and coating will increase the tool life, reduce the scrap rate, and guarantee that the parts comply with the most rigorous certification requirements.

Automotive

Automotive production makes use of a great variety of materials, for example, light aluminum engine parts and hardware, which are made of hardened steel. These steels are used for the production of transmission gears and chassis parts. Each material brings its own difficulties to machining.

Aluminum requires drill bits that have sharp cutting edges and polished flutes for non-sticking of the material and fast chip evacuation. Hardened steels necessitate the use of tools that ensure the edge integrity even in case of high cutting pressures, and hence, they have to be resistant against abrasive wear.

DIN-standard carbide drill bits deliver consistent results for high rigidity and precision. For aluminium applications, uncoated or TiN-coated drills can achieve a very good surface finish. For hardened steels, TiAlN or AlCrN coatings that can withstand increased temperatures are recommended. The right drill geometry for each material type ensures cleaner holes, reduced cycle times, and extended tool life.

Drill Bit Product

Catalog

Click the button below to view our DIN milling cutters catalog and explore detailed product specifications to make the best choice.

General Manufacturing

Stainless steel is a staple across general manufacturing, from food processing equipment to medical devices, yet it is notoriously challenging to drill. Its tendency to work-harden and generate high cutting temperatures means that tool selection has an impact on productivity and finish quality.

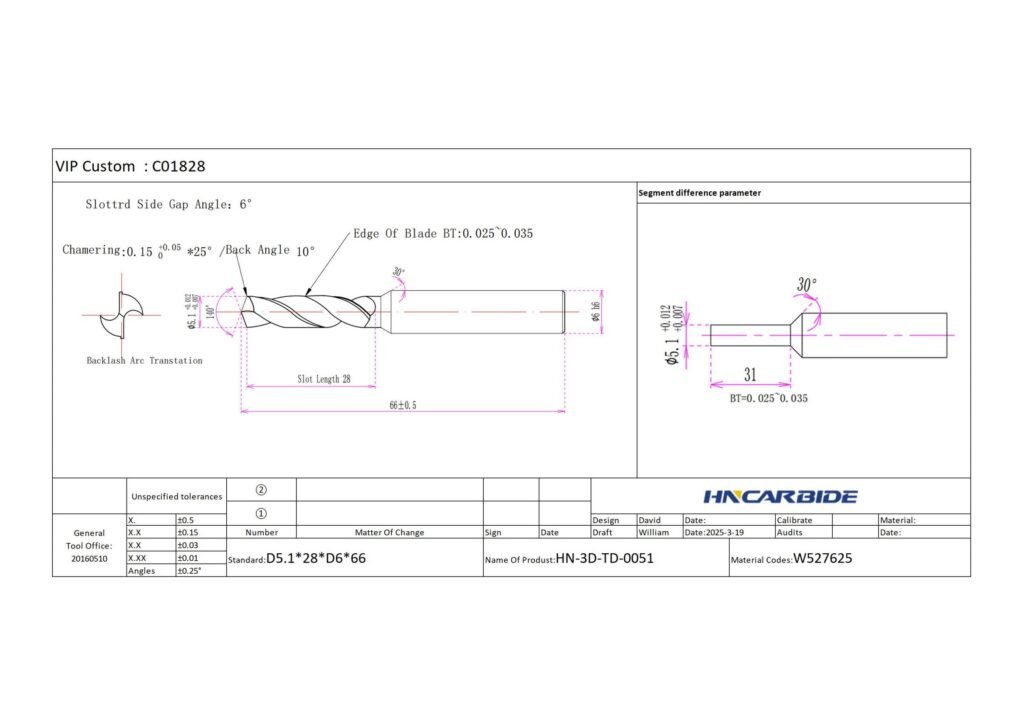

High-speed steel (HSS) drills with cobalt content remain a reliable choice for stainless steel, offering a balance of toughness and heat resistance. For higher-volume production, solid carbide drill bits excel, especially when paired with TiAlN or AlCrN coatings that dissipate heat and reduce friction. Selecting a drill bit with a hole for coolant delivery can further extend tool life and maintain consistent dimensional accuracy by keeping the cutting zone cool.

When combined with the precision of DIN-standard manufacturing, these drill bits maintain consistent diameter control and surface integrity, even in long production runs. This ensures manufacturers can meet tight tolerances while minimising downtime caused by premature tool wear.

Verification and Quality Control

Precision manufacturing depends on more than just selecting the correct drill bit. It requires verification that every tool meets strict dimensional and performance standards. For DIN-standard drill bits, inspection processes focus heavily on diameter accuracy and runout. Even minor deviations can cause oversized holes, poor surface finish, or tool breakage, leading to costly rework or scrap.

Quality control teams typically use optical comparators, coordinate measuring machines (CMMs), and runout testers to ensure that tools meet their specified tolerances. A 6mm drill bit, for example, must consistently measure within the DIN-defined range for both shank and cutting diameter, ensuring compatibility with automated CNC tool holders.

HNCarbide supports this process by providing certificates of origin for full traceability, allowing buyers to confirm material authenticity and compliance with procurement requirements. This documentation is especially valuable for industries such as aerospace, automotive, and medical manufacturing, where supplier verification is non-negotiable.

A well-documented inspection report, paired with verifiable supplier credentials, ensures confidence in every batch of drill bits, whether it’s a standard production run or a custom drill bit with hole design for coolant-fed applications.

Conclusion

DIN standard drill bits provide the precision and consistency that modern CNC manufacturing demands. Their adherence to defined specifications ensures accurate hole dimensions, reduced rework, and predictable tool life, critical factors for industries where tolerances are non-negotiable. When paired with the right material and coating combination, they perform reliably across a wide range of applications, from aerospace components to automotive assemblies.

HNCarbide supports manufacturers with DIN-compliant drill bits backed by complete documentation, including certificates of origin for full traceability. This commitment to verified quality makes it easier to meet procurement and compliance requirements without compromising performance.

Contact HNCarbide today to discuss your drilling needs or request a sample that meets your exact specifications.