This article takes a deep, practical look at the most common spindle taper interfaces, explains how they differ in real-world performance, and helps you choose

This article takes a deep, practical look at the most common spindle taper interfaces, explains how they differ in real-world performance, and helps you choose

In this guide, we take a deep, engineering-focused look at modern drill tools — not from a catalog perspective, but from a real production and

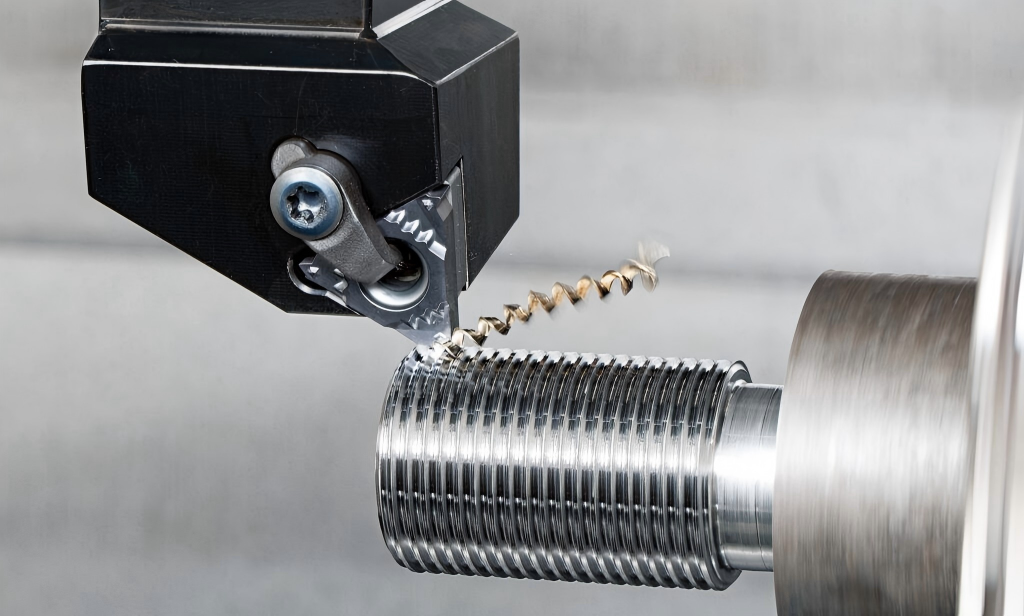

How to Turn Cleaner, Stronger, and More Reliable External Threads on a CNC Lathe

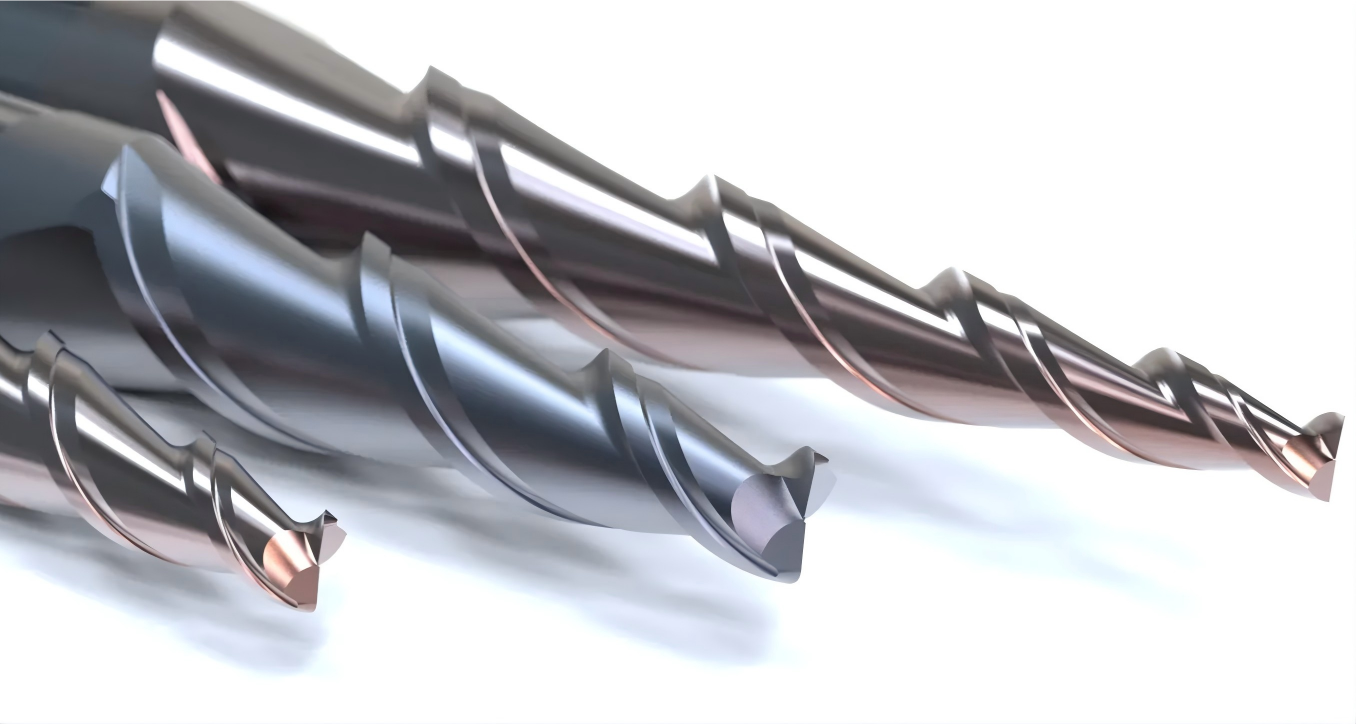

A Practical, Data-Driven Guide for Choosing the Right Geometry

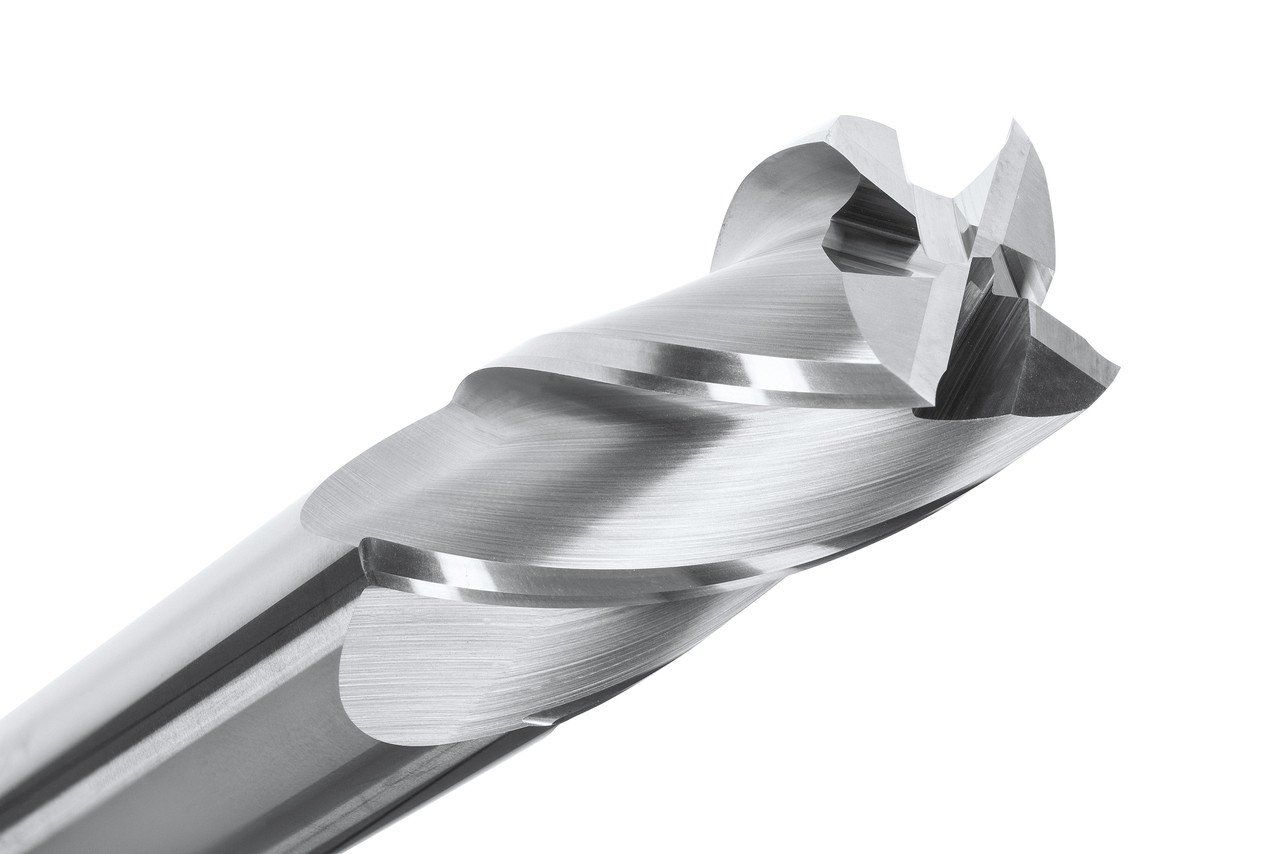

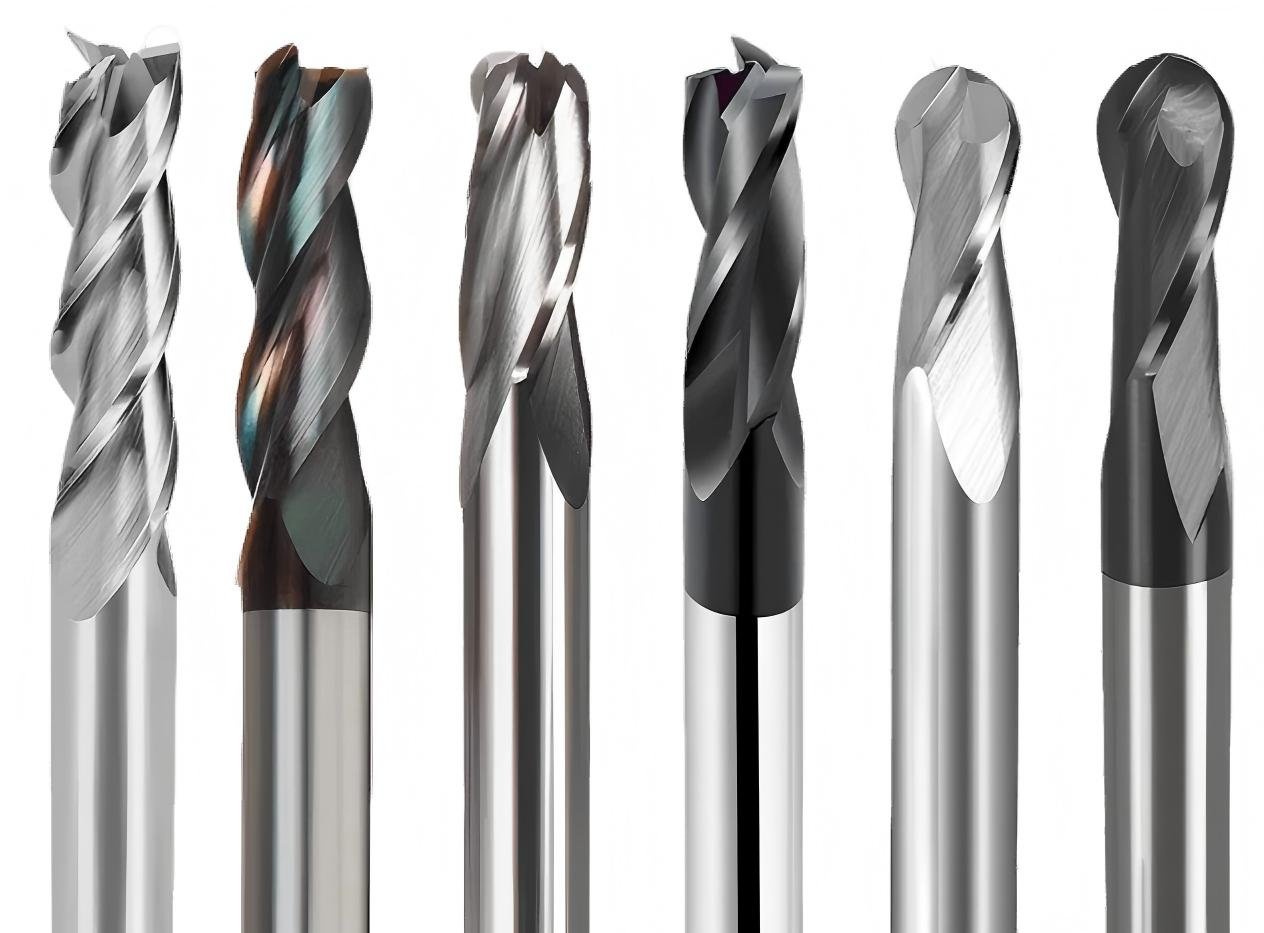

A Deep Technical Guide to Center-Cutting Design, End Geometry, and Real Machining Performance

A Technical Guide to Tungsten Carbide Rod Manufacturing, Microstructure, Grades, and Coolant-Hole Rod Performance

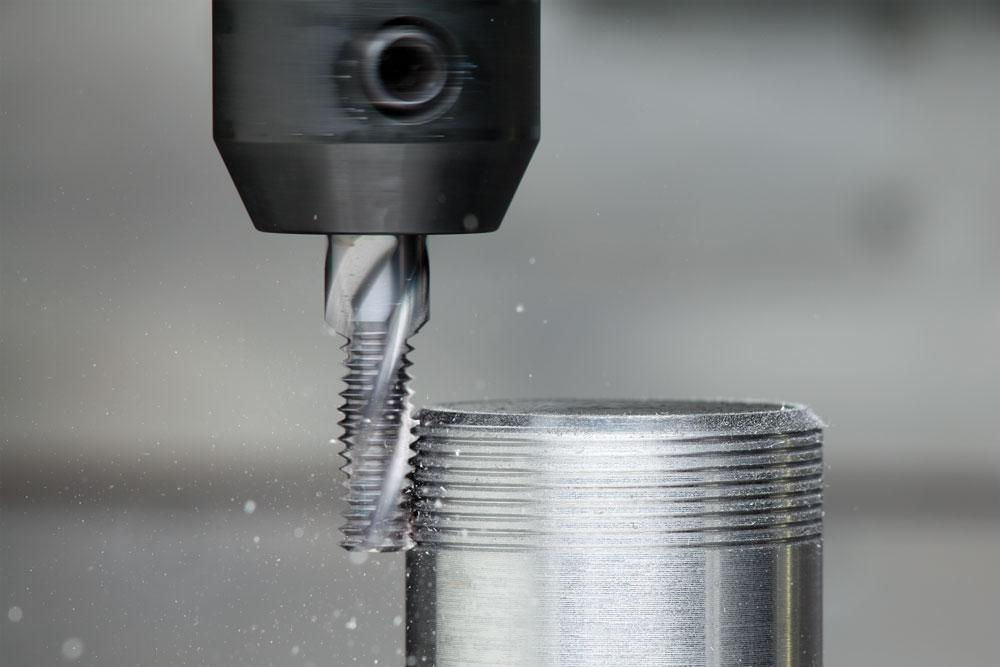

Learn how thread milling works in CNC machining. Compare thread mills vs taps, explore solid carbide thread mills, thread forms, speeds, feeds, and applications.

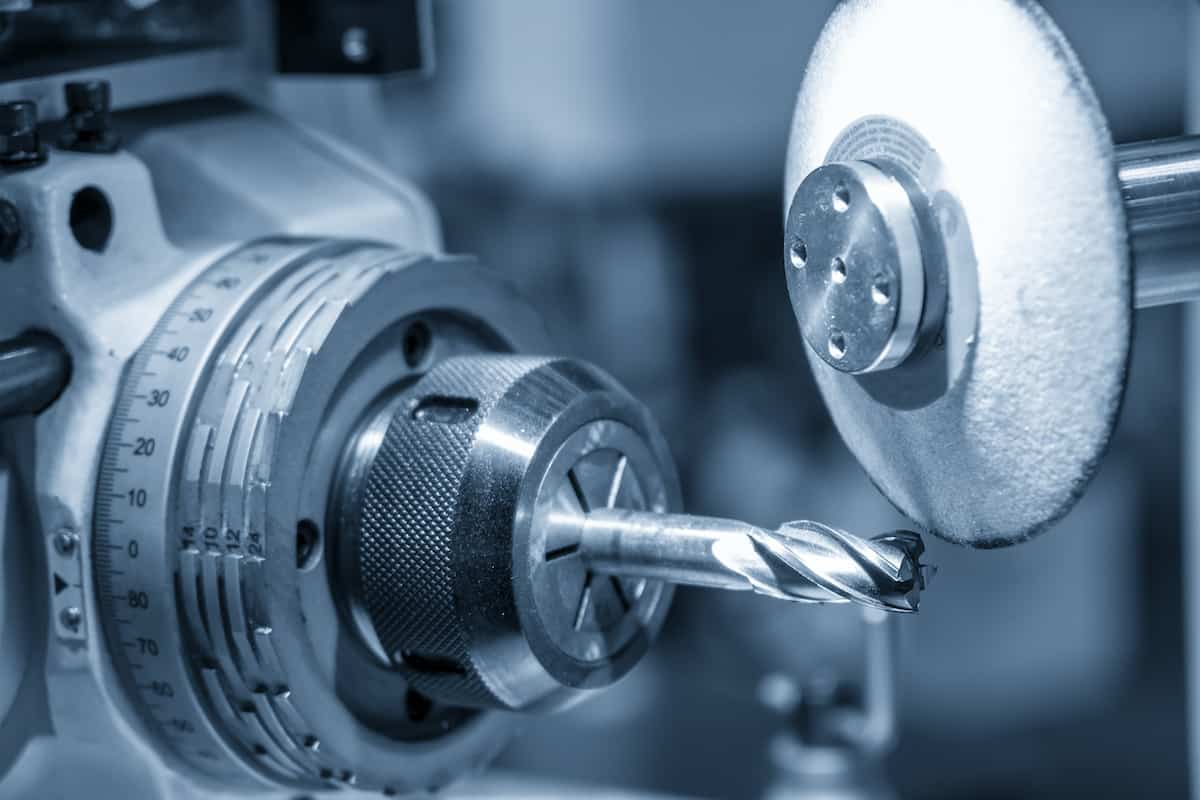

Learn how solid carbide end mill cutter geometry affects cutting performance. Explore rake angle, helix angle, flute design, and professional grinding principles.

Explore grinding wheel types and uses in cutting tool manufacturing, including 1A1, 1V1, 11V9, 12V9, and 6V5 diamond grinding wheels for carbide end mills.

In 2025, the global tungsten market entered a new phase. Prices across the entire upstream chain—ranging from ore and intermediate compounds to tungsten powder and

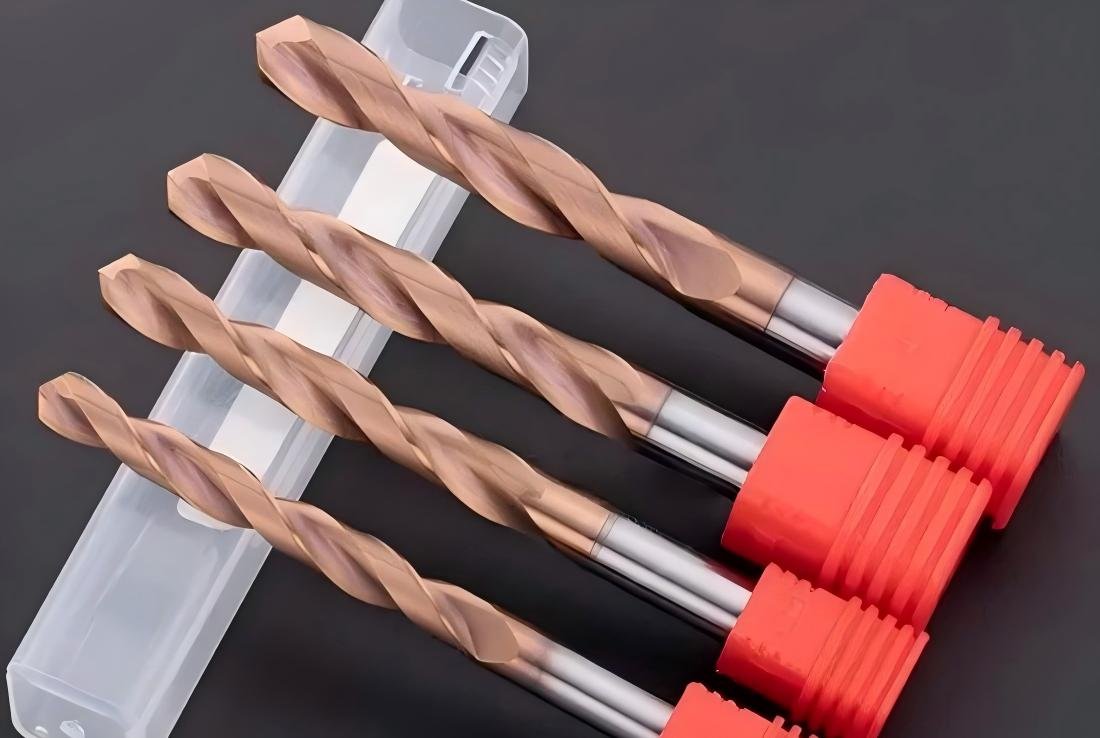

This guide breaks down the seven quality pillars that define industrial-grade solid carbide drill bits: substrate, grind consistency, edge prep, runout/straightness, coating control, inspection discipline,

Hardened steel is unforgiving. It doesn’t “warn you” the way mild steel does—one small setup mistake and the drill chips on entry, squeals, or snaps

This article gives you a practical, verifiable checklist to evaluate a China supplier (factory or trader) for solid carbide drill bits—with special focus on the

Bosch vs DeWalt vs Milwaukee “Carbide” Drill Bit Sets for Metal: What Actually Works Table of Contents Walk into any big-box store (or scroll an

Learn how to choose the best carbide drill bit set for metal—solid carbide vs carbide-tipped, key specs, and what matters for tool life.

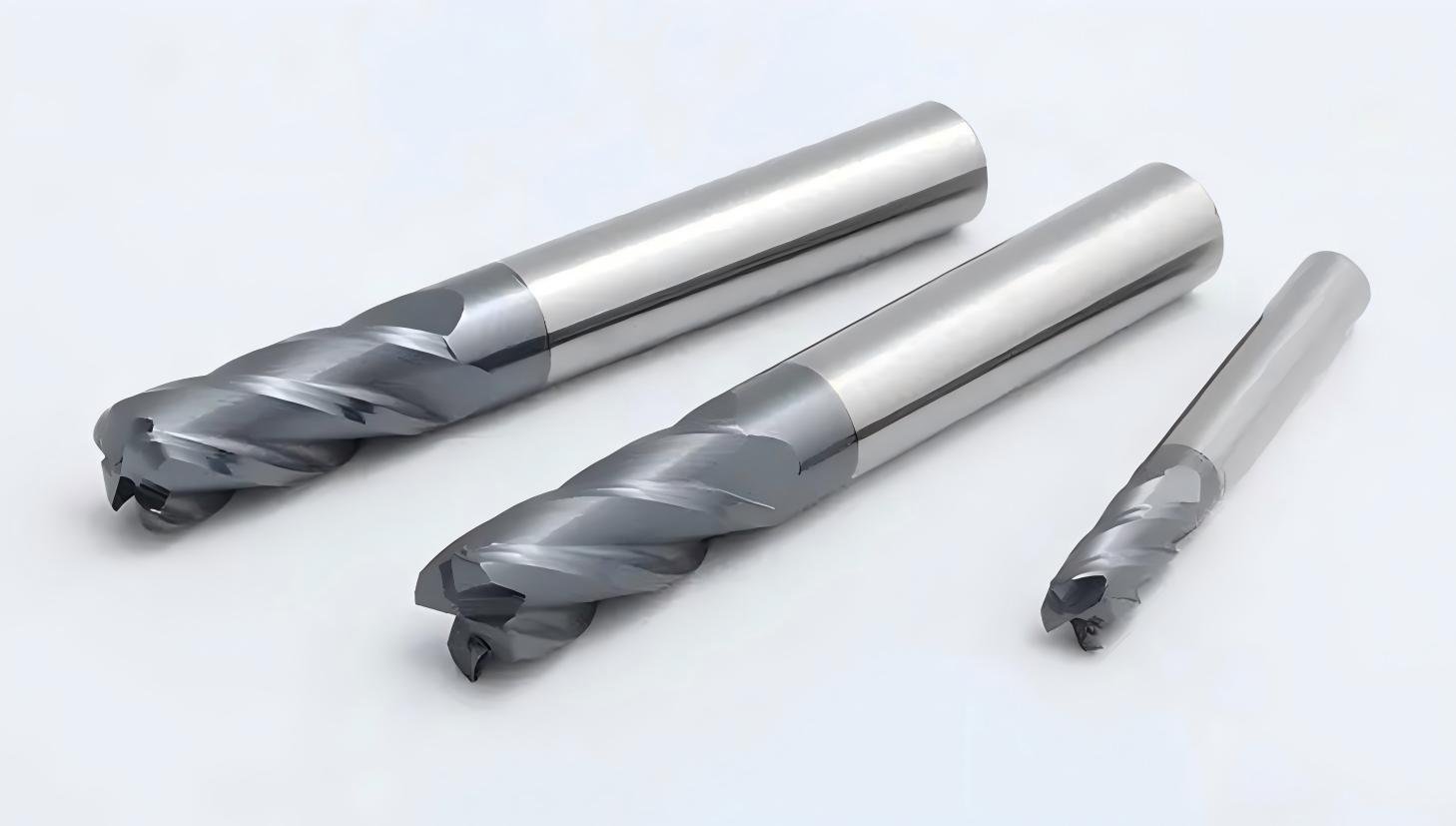

This guide is written for practical selection in steel, stainless steel, aluminum, and general machining—whether you call it an end milling cutter, a milling end

Choosing between an HSS milling cutter end mill and a solid carbide end milling cutter looks like a “tool material” decision. In practice, it’s usually

If you’ve ever swapped a “milling cutter end mill” from Brand A to Brand B—same diameter, same flute count, same program—and the cut suddenly felt

When an end mill milling cutter fails—chips early, leaves poor finish, or suddenly runs undersize—the first instinct is to blame the program: feeds, speeds, stepovers,

This guide is written for distributors, importers, and private-label brands who need a repeatable way to qualify a china end milling cutter supplier—especially for solid

WhatsApp us

Before you go, please note that we offer the most up-to-date industry research reports and the most comprehensive product catalogs, so please contact us if you are interested!

Before you go, please note that we offer the most up-to-date industry research reports and the most comprehensive product catalogs, so please contact us if you are interested!