Beyond Basics: A Practical Guide to Grinding Wheel Types and Uses in Cutting Tool Manufacturing

Table of Contents

In modern cutting tool manufacturing, grinding is no longer a simple finishing process. It is a precision-driven operation that directly determines tool performance, tool life, and machining stability. Whether producing solid carbide end mills, ball nose cutters, or radius tools, the selection of grinding wheel types plays a decisive role.

While many articles discuss grinding wheel types at a general level, few focus on how specific wheel shapes such as 1A1, 1V1, 11V9, 12V9, and 6V5 are actually used in CNC tool grinding. This article aims to close that gap.

In this guide, we will explore grinding wheel types and uses specifically for cutting tool manufacturing, with practical insights into flute grinding, gash grinding, relief angles, and profile forming. You will also find comparison tables and selection charts that can be verified and applied directly on the shop floor.

How Grinding Wheel Types Are Classified in Tool Manufacturing

In industrial practice, grinding wheel classification goes far beyond basic abrasive categories.

For CNC cutting tool production, grinding wheels are typically classified by:

- Wheel shape and geometry

- Grinding operation (flutes, gashes, relief angles, profiles)

- Tool type (end mills, ball nose tools, radius cutters)

- Abrasive material (diamond, CBN)

From an SEO and engineering standpoint, this article focuses on abrasive grinding wheel types used for carbide cutting tools, not general-purpose bench or angle grinder wheels.

Grinding Wheel Types Used in Cutting Tools

Before diving into each wheel type, the following chart provides a structured overview.

Grinding Wheel Types Chart for Cutting Tool Manufacturing

Grinding Wheel Type | Common Name | Primary Applications | Typical Tool Types |

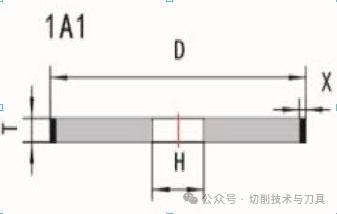

1A1 | Flat grinding wheel | Flute grinding, back grinding, polishing | End mills, 2-flute tools |

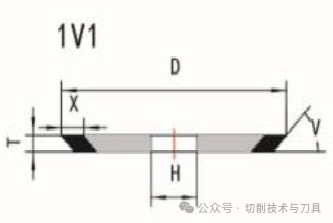

1V1 | Angled grinding wheel | Gash grinding, flute grinding, profile relief | Small & standard end mills |

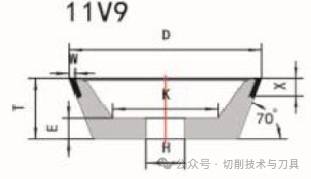

11V9 | Cup grinding wheel | Peripheral relief, end relief, form relief | End mills, form tools |

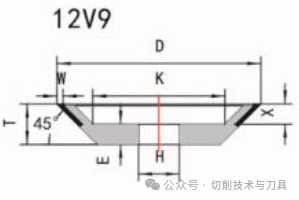

12V9 | Modified cup wheel | Standard gash grinding, profile relief | Standard end mills |

6V5 | Radius grinding wheel | Ball nose & radius forming | Ball nose, R end mills |

This grinding wheel types chart reflects configurations commonly used on modern CNC tool grinders from Europe and Asia.

1A1 Grinding Wheel – The Foundation of Tool Grinding

The 1A1 grinding wheel, often referred to as a flat grinding wheel, is one of the most widely used shapes in tool manufacturing.

Typical Uses

- Flute grinding on end mills

- Back grinding and clearance preparation

- Removing high points on ball nose tools

- Tooth grinding for 2-flute cutters

When equipped with fine grit diamond abrasives, 1A1 wheels are also used for:

- Polishing operations

- Arc relief grinding

- Smooth surface finishing on carbide tools

Practical Insight

In high-volume end mill production, 1A1 wheels are often paired with roughing + finishing strategies, where a coarser grit removes material quickly and a finer grit improves surface integrity.

1V1 Grinding Wheel – Precision for Gashes and Small Diameters

Among all angle grinding wheel types, the 1V1 grinding wheel is arguably the most versatile in CNC tool grinding.

Common Angles and Their Uses

10° / 20° / 30°

- Flute grinding

- Gash grinding

- Polishing operations

- Small-diameter end used for ball nose gashes

45°

- Gash grinding for end mills ≥ 4 mm

55°

- Gash grinding for micro end mills ≤ 4 mm

In addition, 1V1 wheels are frequently used for profile relief grinding, especially where controlled clearance angles are required.

Why 1V1 Wheels Matter

As cutting tools become smaller and more complex, angle grinder grinding wheel types for cutting tools must offer both accessibility and precision. The narrow profile of 1V1 wheels allows consistent chip space geometry without excessive wheel interference.

11V9 Cup Grinding Wheel – Mastering Relief Angles

The 11V9 grinding wheel, commonly known as a cup grinding wheel, is essential for relief angle operations.

Main Applications

- Peripheral (radial) relief grinding

- End relief grinding

- Form relief on profiled tools

Performance Advantage

Compared to flat wheels, cup grinding wheel types provide:

- Better angle stability

- Consistent contact geometry

- Improved surface finish on relief faces

For carbide end mills used in high-speed machining, accurate relief angles are critical to reduce cutting forces and heat generation.

12V9 Grinding Wheel – Efficiency for Standard End Mills

The 12V9 grinding wheel is widely applied in standard end mill production, particularly for gash grinding.

Key Uses

- Standard flute gashing

- Profile relief grinding

Why Manufacturers Choose 12V9

12V9 wheels strike a balance between:

- Material removal rate

- Wheel stability

- Ease of programming on CNC grinders

They are especially popular in mass production environments, where consistency and efficiency matter more than extreme customization.

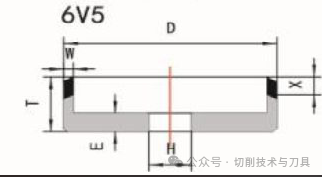

6V5 Grinding Wheel – For Ball Nose and Radius Tools

When it comes to complex geometries, the 6V5 grinding wheel becomes indispensable.

Typical Applications

- Ball nose end mill grinding

- Radius (R) end mill forming

- Arc and radius relief grinding

Technical Consideration

Ball nose tools demand smooth transitions and precise curvature. 6V5 wheels are designed to maintain stable arc geometry, minimizing mismatch between programmed and actual tool profiles.

Diamond Grinding Wheel Types vs CBN in Carbide Tools

For carbide tool manufacturing, diamond grinding wheel types dominate due to their superior hardness.

Diamond vs CBN Grinding Wheels in Tool Manufacturing

Property | Diamond Grinding Wheel | CBN Grinding Wheel |

Best for | Carbide tools | HSS tools |

Hardness | Extremely high | Very high |

Thermal stability | Moderate | Excellent |

Typical use | End mills, ball nose tools | Drills, taps (HSS) |

For solid carbide cutting tools, diamond abrasives remain the industry standard.

Grinding Wheel Selection by Tool Operation

Selecting the right grinding wheel is not only about shape—it is about matching wheel geometry to the grinding operation.

Grinding Wheel Selection Chart by Operation

Grinding Operation | Recommended Wheel Type | Notes |

Flute grinding | 1A1 / 1V1 | Choose grit by surface requirement |

Gash grinding | 1V1 / 12V9 | Angle depends on tool diameter |

Peripheral relief | 11V9 | Stable relief angles |

End relief | 11V9 | Common for end mills |

Ball nose forming | 6V5 | Radius accuracy critical |

This table can also serve as a grinding wheel types chart PDF reference for engineers and buyers.

Surface Grinding Wheel Types and Finish Quality

Although often overlooked, surface grinding wheel types influence:

- Cutting edge sharpness

- Coating adhesion

- Tool life in high-speed machining

Fine-grit diamond wheels combined with optimized coolant delivery significantly reduce micro-chipping on carbide edges.

Conclusion

Understanding grinding wheel types and uses is no longer optional in modern cutting tool manufacturing. From 1A1 flat wheels to 6V5 radius wheels, each shape serves a specific purpose that directly impacts tool quality and performance.

By selecting the right abrasive grinding wheel types, manufacturers can:

- Improve tool life

- Enhance machining stability

- Reduce scrap rates

- Achieve consistent, repeatable results

As cutting tools evolve toward smaller diameters and more complex geometries, grinding wheel selection will continue to be a key competitive advantage.