Why DIN Standard End Mills Are the Benchmark for European CNC Machining

Explore why DIN standard & ball carbide end mills deliver precision, durability & CNC compatibility for aerospace, automotive, mold and medical manufacturing.

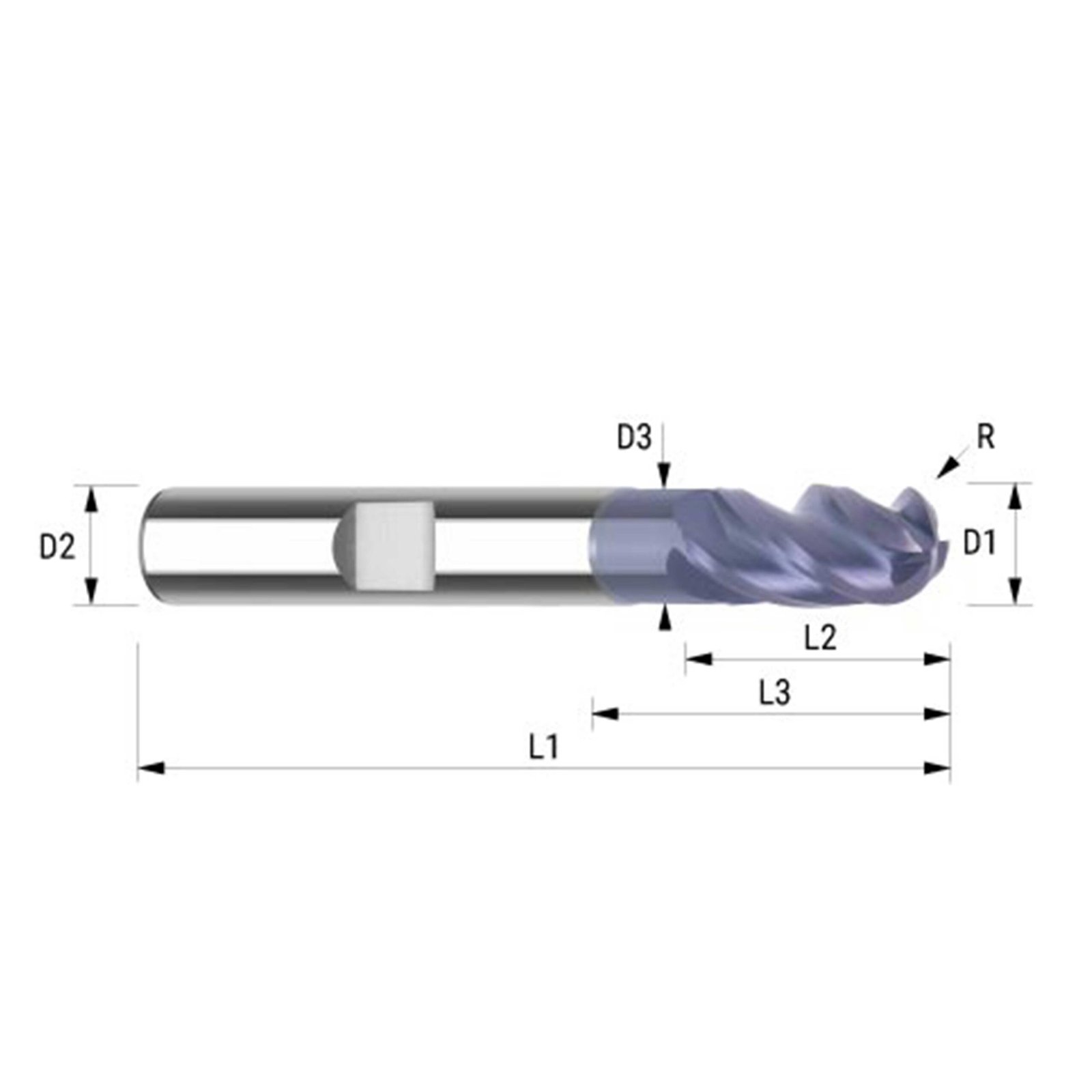

Ball nose geometry for 3D contouring and curved surfaces

2-flute design for efficient chip evacuation

HB shank (Weldon flat) for secure clamping

Made from high-performance solid carbide

Compliant with DIN standard dimensions

Suitable for semi-finishing to finishing operations

Tool data

Description

This 2-flute GP ball nose milling cutter from the DIN series is designed for high-precision profiling and contouring. With a hemispherical cutting edge, it is ideal for 3D surface machining in dies, molds, and complex components.

Manufactured with HB shank (Weldon flat) and optimized flute geometry, it offers excellent chip evacuation and surface finish, especially in softer steels, alloyed materials, and non-ferrous metals. Designed according to DIN standards for compatibility and reliability in general-purpose (GP) CNC milling.

1.Profiling and finishing in mold & die making, aerospace, and general machining

2.Ideal for 3D contour milling, slotting, and pocketing

3.Effective on tool steel, alloy steel, aluminum, and plastics

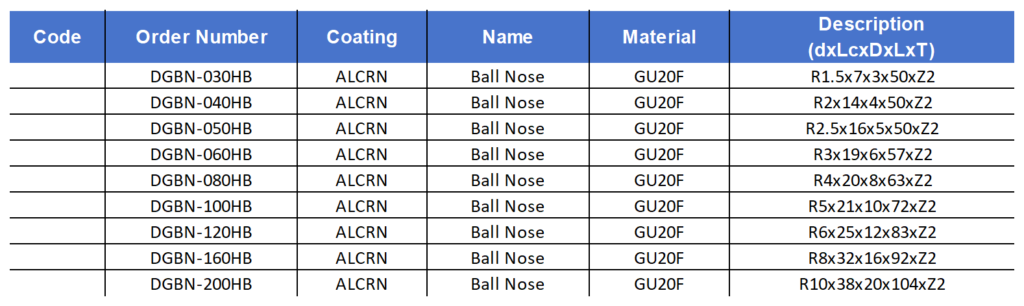

| Code | Order Number | Coating | Name | Material | Description(dxLcxDxLxT) |

|---|---|---|---|---|---|

| XD4857 | DGBN-030HB | ALCRN | Ball Nose | GU20F | R1.5x7x3x50xZ2 |

| XD4858 | DGBN-040HB | ALCRN | Ball Nose | GU20F | R2x14x4x50xZ2 |

| XD4859 | DGBN-050HB | ALCRN | Ball Nose | GU20F | R2.5x16x5x50xZ2 |

| XD4860 | DGBN-060HB | ALCRN | Ball Nose | GU20F | R3x19x6x57xZ2 |

| XD4861 | DGBN-080HB | ALCRN | Ball Nose | GU20F | R4x20x8x63xZ2 |

| XD4862 | DGBN-100HB | ALCRN | Ball Nose | GU20F | R5x21x10x72xZ2 |

| XD4863 | DGBN-120HB | ALCRN | Ball Nose | GU20F | R6x25x12x83xZ2 |

| XD4864 | DGBN-160HB | ALCRN | Ball Nose | GU20F | R8x32x16x92xZ2 |

| XD4865 | DGBN-200HB | ALCRN | Ball Nose | GU20F | R10x38x20x104xZ2 |

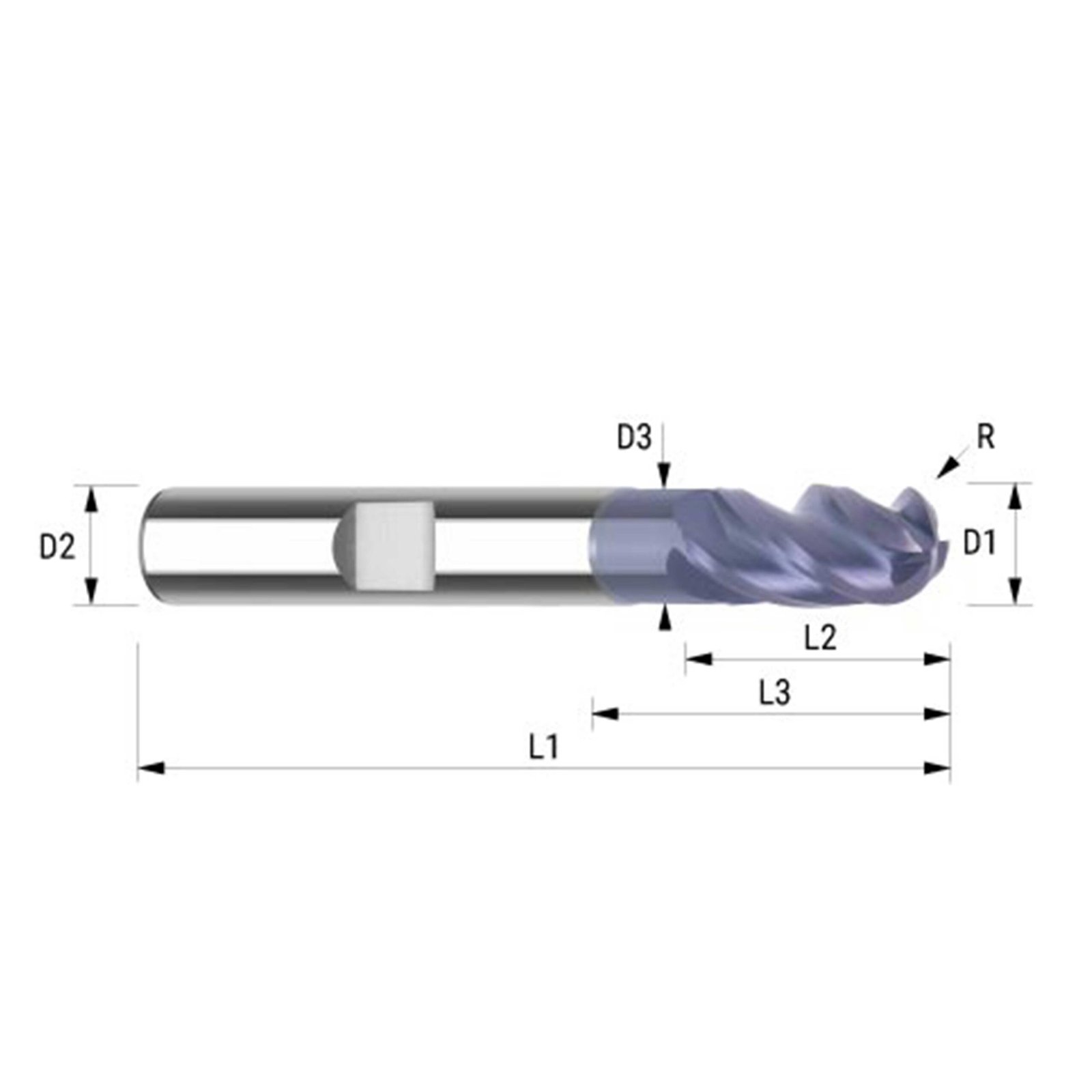

Ball nose design for contour milling and 3D shapes

2-flute geometry for clean chip flow and better surface finish

HA (straight) shank for precise tool holding

Solid carbide construction for wear resistance

Complies with DIN standard dimensions

Designed for semi-finishing and finishing work

Tool data

Description

This 2-flute ball nose milling cutter from the DIN GP series features a universal HA straight shank, providing high concentricity for precision milling. Designed for 3D profiling and curved surface machining, it delivers excellent surface finish and control in complex contours.

Crafted from solid carbide, the tool offers enhanced rigidity and durability. The 2-flute ball nose geometry ensures smooth chip evacuation and is especially suitable for softer materials and non-ferrous metals. Manufactured in compliance with DIN standards for general-purpose applications.

1.Ideal for 3D machining in molds, dies, and complex profiles

2.Works effectively on alloy steels, aluminum, copper, and plastics

3.Compatible with high-speed CNC milling for finishing and light roughing

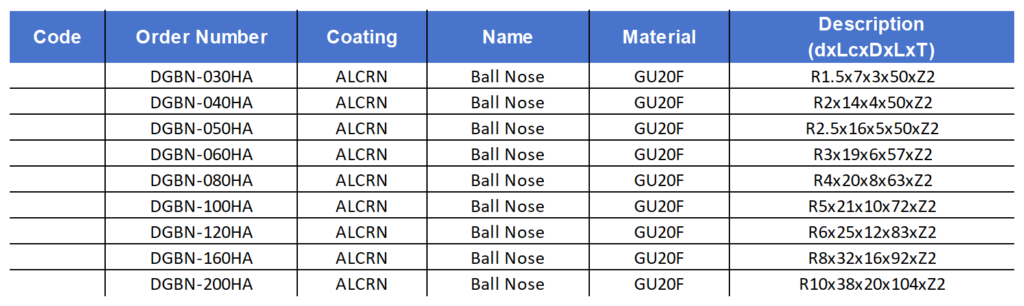

| Code | Order Number | Coating | Name | Material | Description(dxLcxDxLxT) |

|---|---|---|---|---|---|

| XD4866 | DGBN-030HA | ALCRN | Ball Nose | GU20F | R1.5x7x3x50xZ2 |

| XD4867 | DGBN-040HA | ALCRN | Ball Nose | GU20F | R2x14x4x50xZ2 |

| XD4868 | DGBN-050HA | ALCRN | Ball Nose | GU20F | R2.5x16x5x50xZ2 |

| XD4869 | DGBN-060HA | ALCRN | Ball Nose | GU20F | R3x19x6x57xZ2 |

| XD4870 | DGBN-080HA | ALCRN | Ball Nose | GU20F | R4x20x8x63xZ2 |

| XD4871 | DGBN-100HA | ALCRN | Ball Nose | GU20F | R5x21x10x72xZ2 |

| XD4872 | DGBN-120HA | ALCRN | Ball Nose | GU20F | R6x25x12x83xZ2 |

| XD4873 | DGBN-160HA | ALCRN | Ball Nose | GU20F | R8x32x16x92xZ2 |

| XD4874 | DGBN-200HA | ALCRN | Ball Nose | GU20F | R10x38x20x104xZ2 |

Explore why DIN standard & ball carbide end mills deliver precision, durability & CNC compatibility for aerospace, automotive, mold and medical manufacturing.

Discover Italy's top 5 end mill manufacturers known for precision, durability, and innovative design across automotive, mould, and energy industries.

Modern CNC machining doesn’t run on raw horsepower alone. Tool coatings have become just as critical as cutter geometry, especially in operations where speed, temperature, and precision need to be balanced with one another.

WhatsApp us

Before you go, please note that we offer the most up-to-date industry research reports and the most comprehensive product catalogs, so please contact us if you are interested!

Before you go, please note that we offer the most up-to-date industry research reports and the most comprehensive product catalogs, so please contact us if you are interested!