Application of HRC 55–58 Aluminum Spiral End Mills in Automotive Lightweight Components

Table of Contents

A defining direction in automotive manufacturing has become weight reduction as manufacturers strive to reduce vehicle mass without compromising strength and integrity. The main thrust of this effort is centered on aluminum since it provides excellent strength-to-weight ratio possibilities and broad design potential. However, challenges are brought to light in machining aluminum components for structural and precision applications.

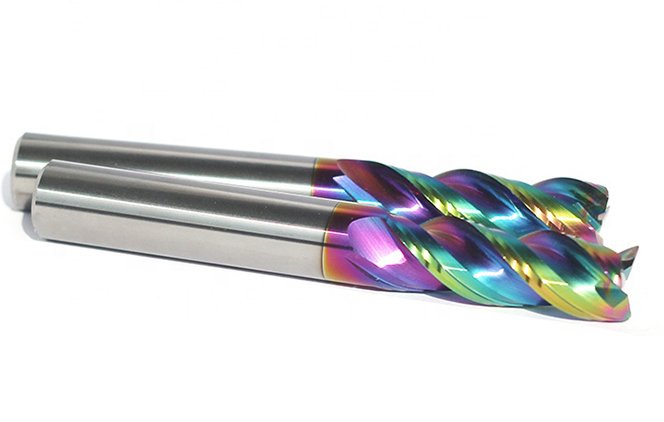

Surface finish, dimensional accuracy, and machining speed are factors highly dependent on the cutting tool. The hardness range is at HRC 55–58 with a spiral flute design and modern coatings, such that end mills can perform with stability under demanding conditions. These are tools designed not only for efficiency but for the consistency of quality that is a requirement of Germany’s competitive automotive supply chain.

In this blog, we will discuss the characteristics, uses, and factors of machining that lead manufacturers to greater productivity and reliability when conducting aluminum part machining.

DIN Milling Cutters Catalog

Click the button below to view our DIN milling cutters catalog and explore detailed product specifications to make the best choice.

Tool Features

The choice of end mill design for aluminum machining involves much more than just the hardness of the material. Geometry, coating, and flute structure play an integral role in striking a balance between cutting efficiency and surface quality.

HRC 55–58 Hardness for Stability

End mills made from material rated at HRC 55–58 hardness offer an excellent combination of strength and toughness for the machining of aluminum. This range will not wear out too quickly; neither will it be brittle, so that it can retain a sharp cutting edge through extended production runs.

This is the hardness window preferred by automotive suppliers in Germany, who are often high-volume series producers because of its consistency and predictable performance.

Common benefits include:

- Maintains edge sharpness under high spindle speeds

- Reduces deformation in long production runs

- Provides reliable wear resistance without brittleness

- Supports stable machining in lightweight automotive parts

This combination of properties makes HRC 55–58 spiral end mills an efficient choice for balancing productivity, tool life, and surface finish quality.

Spiral Flute Design for Chip Evacuation

Spiral flute geometry is important in machining aluminum, particularly when automotive lightweight parts are concerned. It is actually the open flute that allows for smooth chip evacuation from the cutting zone. Hence, there will be no clogging, which may otherwise result in workpiece surface damage or reduced tool life.

Quick chip removal for fast work, mostly in thin walls, lowers the cutting force and the amount of heat generated. This helps both size accuracy and surface quality.

Advantages of spiral flute design include:

- Faster chip removal at high spindle speeds

- Lower cutting force for improved stability

- Reduced risk of aluminum adhesion to the cutting edge

- Better surface quality on structural and thin-walled parts

By combining geometry with even hardness, spiral end mills provide consistent performance across automotive aluminum cutting jobs.

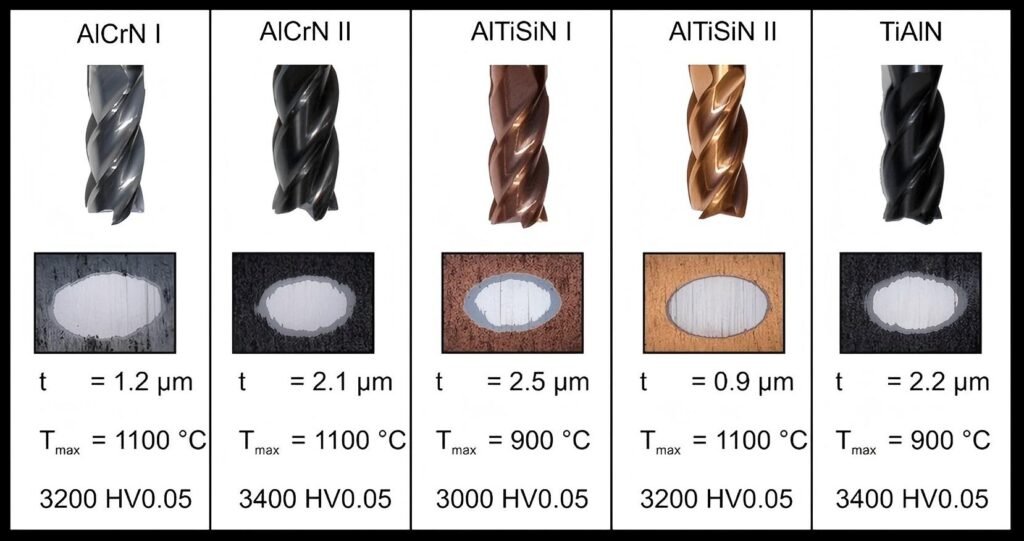

Coatings to Improve Wear Resistance and Prevent Aluminum Adhesion

When milling aluminum, coatings applied on spiral end mills become a vital factor towards tool life and sustaining the process. The propensity of aluminum to stick on cutting edges tremendously reduces tool life, creates visible marks with which the tools can be identified, and degrades surface finish.

Coating spiral end mills of hardness HRC 55–58 with the appropriate coat helps in retaining the efficiency of cutting and preventing adhesion, thereby increasing general productivity in a precision machining environment.

Coating Type | Benefits | Best Applications |

DLC (Diamond-Like Carbon) | Extremely low friction and excellent adherence prevention | High-speed finishing, thin-wall, and mirror surfaces |

TiB₂ (Titanium Diboride) | Reduces aluminum buildup and increases wear resistance | General aluminum machining with moderate speeds |

AlTiN / TiAlN | Good wear resistance and heat stability | Mixed-material operations, including harder sections |

CrN (Chromium Nitride) | Corrosion resistance, moderate adhesion control | Coated aluminum or mixed non-ferrous environments |

Note: DLC and TiB₂ excel at preventing aluminum sticking, while AlTiN/TiAlN and CrN offer extra protection where higher machining speeds or mixed components are involved.

German automotive manufacturers put minimal interruptions and high repeatability at the top of their list. Surface finish and subsequent polishing or reworking that is much lower add to tool life directly from the right coating selection, making an application more efficient and cost-effective.

Practical Applications

Machining techniques are important in maintaining dimensional accuracy while facilitating production time savings. HRC 55–58 spiral end mills serve as a critical determinant for aluminum component machining, where precision and repeatability must be ensured, together with cost-effectiveness. Geometry and coating combinations make them suitable to respond to the various needs required by structural and finishing operations.

Slotting Aluminum Structural Components

Structural parts in vehicles, such as engine brackets, transmission housings, and suspension supports, require precise slotting for both assembly and the functionality of load-bearing components. Spiral end mills with a hardness of 55–58 HRC produce stable cutting edges that suppress chatter, even if larger slots are being machined.

Besides their sharp cutting profiles, polished flutes also help to evacuate aluminum chips quickly, so that there is no tool clogging and thermal distortion.

Automotive plants in Germany use these properties for the benefit of a high number of pieces, where the tight tolerance and surface integrity result in less rework in the downstream process. In reality, the slotting operations can accomplish both feed rate speed and coolant-assisted strategies for stability, thus a contribution is made to the reduction of cycle times without compromising the reliability of the component.

Surface Finishing on Thin-Walled Parts

Thin-walled aluminum parts, such as body panels, battery housings, or electronic casings, are the ones that need delicate finishing for the surface that directly impacts the quality of the performance and aesthetics. Spiral end mills within this hardness range support stable engagement and prevent deflection, which is a common problem in thin-wall machining.

Coatings such as DLC or TiB₂ make it less likely for aluminum to stick to the surface, thereby enabling smoother finishing and lower polishing requirements. Vibration control is an indispensable element in the high-speed finishing operations that are typical for German automotive suppliers.

By using precision tool holders and a coolant-through design, spiral end mills deliver a controlled cutting action with very little heat generation. The outcome is surface finishing that constantly achieves Ra < 0.4 µm specification, diminishing the amount of manual finishing labor and the level of repeatability of production batches.

Complex Contour Machining

One way car manufacturers can reduce a vehicle’s weight is by using intricate aluminum structures, which may involve three-dimensional contours of cylinder heads, frame ribs, or air flow housings. Among different cutting tools, spiral end mills that have been prepared for a hardness of HRC 55-58 are most suited for such cases, as they have both the required strength and the necessary sharpness.

The spiral flute geometry allows the chips to be removed in a curved path in a very smooth way, while the optimized coatings prevent the built-up edge from forming during long tool paths. German manufacturers make use of this benefit in 5-axis machining centers, where the dynamic tool paths are the reason for such high stress on the tool edge.

Spiral end mills enable contour machining with minimal tool wear when combined with appropriate cutting parameters and a stable tool holding system, ensuring tool life meets demanding production schedules.

Recommended Machining Parameters

Machining aluminum lightweight components with properly balanced parameters is a challenge that results in both high productivity and stable surface finishes. The softness and ductility of the aluminum are the reasons for chip adhesion, tool clogging, and vibration if the cutting values are not optimized.

Tools in the HRC 55–58 range, when combined with the correct cutting speed, feed rate, and depth of cut, are capable of removing the metal in an efficient way while maintaining the stability of the tool. In German automotive production environments, even the smallest changes in the spindle speed or the delivery of the coolant can have a considerable effect on the surface quality and the tool life.

Cutting Speed

Lightweight automotive components in aluminum are best machined with a spiral end mill that have HRC 55–58 hardness and are able to balance cutting speed, tool life, and surface consistency. The tools will be at their most efficient when used at specific speed ranges, which makes it possible to achieve high productivity without sacrificing edge integrity.

When using HSS tools, try to attain cutting speeds of about 300–500 SFM (surface feet per minute), or roughly 90–150 m/min if you are working in metric.

Such a choice of speeds allows the best possible removal of the metal without the occurrence of tool clogging, which is usually caused when aluminum is machined at high speeds.

Speed Recommendations: Cutting Speed vs. RPM

Cutting Speed (SFM) | Cutting Speed (m/min) | Recommended RPM for 8 mm End Mill |

400 SFM | ~122 m/min | ~4,900 RPM |

600 SFM | ~183 m/min | ~7,400 RPM |

Calculation formula: RPM = (Cutting speed × 3,820) / Cutter diameter (mm)

By using the right cutting speed for aluminum, cutting heat and material smearing can be avoided. “Alu-power” or “ALU-POWER HPC” is part of a high-performance series that can operate at speeds up to 35,000 rpm, thus providing a great result for German sophisticated set-ups. The method stabilizes the life of the tool, cutting profiles, and the cleaning of chips. It gives smaller production margins for complicated automotive parts.

Feed Rate

Choosing the right spindle speed and feed rate is equally important when using a spiral end mill for aluminum. The feed per tooth directly influences tool stability, chip evacuation, and final surface quality. A low feed could lead to the tool rubbing instead of cutting, while if the feed is too high, deflection or chatter are likely to occur.

A practical range for aluminum machining is:

- Finishing:025–0.035 mm per tooth (smoother surface finish, lower cutting force).

- General machining:04–0.06 mm per tooth (balanced productivity and finish).

- Roughing:up to 0.07–0.08 mm per tooth (faster material removal but higher load).

The variables that affect the correct feed rate are the diameter of the cutter, the number of flutes, and the rigidity of the tool holder and workpiece setup.

Vibrations are the source of most problems when dealing with thin-walled aluminum components in the automotive sector. Slightly lowered feeds can be used in that instance to both prevent vibration and maintain chip evacuation at a good rate.

A properly selected feed rate supports:

- Stable tool engagement across the cut

- Improved surface finish consistency

- Reduced wear on the cutting edges

- Longer tool life, lowering per-part cost

Depth of Cut

Depth of cut not only indicates the amount of material removed from a single pass but also has a direct bearing on machining efficiency and tool life. With a spiral end mill made for aluminum, the depth of cut has to be decided based on the tool diameter, rigidity of the setup, and the stage of the machining process.

Typically, the first stage of the 50-55 HRC steel part is achieved through righting operations, which involve performing a deep cut to remove as much material as possible, while also generating higher cutting forces. In the case of thin-walled aluminum automotive parts, the overuse of depth can lead to chatter or deflection. Finishing operations, however, provide the use of lighter depths; hence, obtaining the desired surface quality while also minimizing the tool’s stress.

As a rule, it is recommended to maintain the axial depth of cut with a value from 0.5 to 1.5 times the tool diameter for roughing. In contrast, the radial engagement is lowered to avoid an overloading of the cutting tool. When it comes to finishing, lower depths of 0.2–0.4 times the diameter are more appropriate, yielding a nice surface.

A balanced approach is essential: deeper cuts improve efficiency but shorten tool life, while lighter passes enhance surface finish but increase cycle time. Selecting the right depth of cut for the specific automotive component helps achieve both precision and cost efficiency.

Coolant Usage and Internal Cooling Strategies

Efficient coolant delivery is important when machining lightweight aluminum components. Proper cooling prevents built-up edge, maintains surface quality, and extends tool life. In high-speed operations, flood coolant helps flush chips from the cutting zone, reducing the risk of recutting.

Internal coolant-through spiral end mills are often preferred for deeper slotting or contouring. These deliver coolant directly to the cutting edge, improving chip evacuation and reducing thermal load. In thin-walled automotive parts, where vibration and deflection are concerns, steady coolant flow also stabilizes the cut.

Choosing between external flood coolant and internal cooling depends on tool design and component geometry, but both strategies significantly improve efficiency in aluminum machining.

Challenges & Optimization

Machining lightweight automotive components with aluminum presents unique challenges that can affect productivity and quality. While spiral end mills are designed to handle these tasks efficiently, consistent performance depends on addressing two recurring issues.

- Preventing Chip Clogging or Aluminum Adhesion

Aluminum tends to produce long, continuous chips that may clog the cutting zone. This increases cutting force and risks tool breakage. Optimized flute geometry, high-polish surfaces, and coatings like TiB₂ help reduce adhesion, keeping the cutting edge clean. - Extending Tool Life and Maintaining Machining Accuracy

High-speed machining of aluminum can accelerate edge wear, especially when cutting thin-walled parts. Balancing cutting speed with controlled feed rates, combined with effective coolant delivery, helps extend tool life. Precision tool holding also plays a role in sustaining dimensional accuracy over longer runs.

Addressing these challenges through proper tooling choices and machining strategies allows manufacturers to maintain stable processes, minimize downtime, and achieve the desired surface finish in aluminum automotive components.