Application of 55 HRC Deep Groove End Mills in Dental Prosthetics

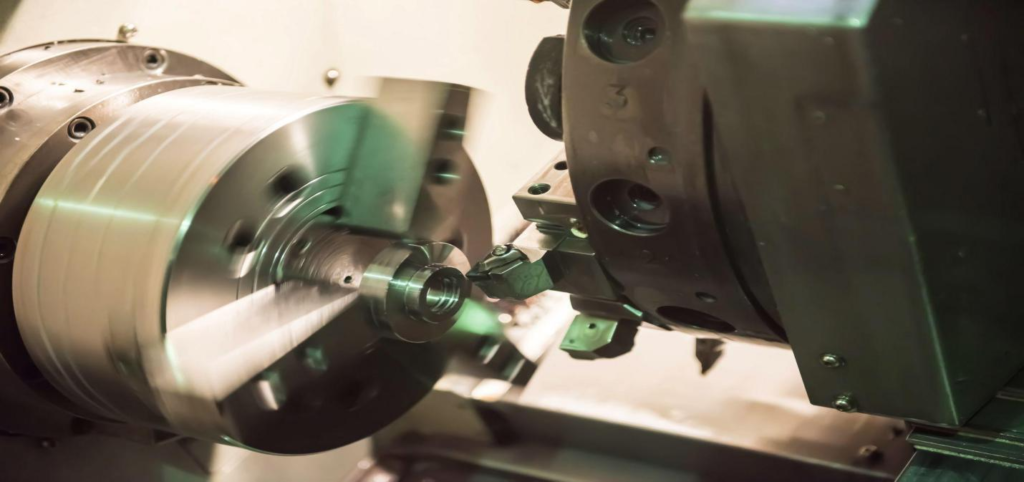

Dental prosthetics need high accuracy, long-term performance, and a smooth, uniform surface finish. All crowns, bridges, or implant parts must have very close tolerances to fit correctly and function properly over the long term within the mouth. This makes the selection of cutting tools an important consideration in dental machining.

Among the options presented, 55 HRC Deep Groove End Mills are especially suitable for hard dental alloys machining. They are designed to keep sharp cutting edges, dimensional stability, and wear resistance, ideal for contouring intricate details such as crown cavities and occlusal surfaces.

To German dental labs and medical device manufacturers, who have a reputation for precision engineering and state-of-the-art CNC procedures, these instruments provide a consistent blend of performance and reliability that maximizes both the quality of the prosthetics and productivity.

Role of Precision and Wear Resistance in Dental Prosthetics

The oral health sector is special in that instruments are required to achieve a micro level of precision while operating on extremely demanding material. Cobalt-chrome alloys, titanium, and hybrid ceramics require instruments that resist intense wear, heat, and vibration, yet still deliver smooth accurate surfaces.

Accuracy is highly important as a 10 µm variation can affect crown or bridge fit and comfort. Firm wear resistance maintains the cutting edge sharp throughout extended production runs, minimizing the number of tool changes and downtime. Uniform surface quality also decreases polishing and post-processing time, directly slashing overall costs.

Tool geometry and hardness are central to the accomplishment of these outcomes. 55 HRC hardness deep groove end mills are stable under cutting forces and feature a bespoke flute design for the removal of chips efficiently, an important consideration when machining the thin walls of dental prosthetics.

Tool Features

Emphasizing the material and design aspects that enhance performance in dental milling:

1. Benefits of 55 HRC Hardness for Dental Crowns

Deep groove end mills in the 55 HRC range offer an optimal combination of toughness and wear resistance. This level of hardness for tools performs well when machining cobalt-chrome or titanium, which is used extensively in dental crowns.

- Improved tool stability and increased edge retention.

- Longer tool life versus tools with hardness levels below 50 HRC.

- Fine for roughing as well as finishing applications in dental labs.

2. Deep Groove Design for Effective Chip Evacuation

The long, shallow flutes of these Deep groove end mills enable chips to flow out readily, even in narrow crown cavities or deep occlusal grooves. This reduces the chances of chip recutting, which would otherwise result in surface burns, inaccuracies, or tool breakage.

3. Advanced Coatings: TiN, ZrN and AlCrN

- TiN (Titanium Nitride):Friction-reducing and ideal for general dental milling.

- ZrN (Zirconium Nitride):Prevents built up edge, especially when machining non-ferrous alloys.

- AlCrN (Aluminum Chromium Nitride):Provides superior thermal resistance, best suited for dry or high-speed machining of cobalt-chrome materials.

The application of coated tools extends tool life and yields smoother surfaces, reducing the necessity for additional polishing or rework.

Practical Applications

Some of the ways in which these end mills are applied to precise dental prosthetic machining:

1. Rough Machining of Crown Inner Walls

Dental crowns have their inner cavities to be shaped highly accurately. The 55 HRC hardness deep groove end mills are capable of performing aggressive material removal while maintaining their sharp edges, so they are well suited for roughing such areas effectively.

2. Deep Groove Cutting for Occlusal Surfaces

Occlusal molars possess intricate grooves and fissures. Deep groove milling cutters make it possible to accurately mill these details without compromising chip removal. German dental laboratories tend to use 4-flute or coated tools for consistent cutting at higher feed speeds.

3. Fine Trimming at Dental Bridge Connection Areas

Bridge connectors need extremely fine milling to achieve close tolerances. In tight locations, a 2-flute or long reach end mill is typically utilized for finishing. Coatings such as AlCrN assist in maintaining the cutting edge sharp and retaining a smooth surface finish on the workpiece.

Recommended Machining Parameters

With 55 HRC deep groove end mills in dental alloys, machining parameters are to be set correctly:

Tool Diameter (mm) | Cutting Speed (m/min) | Feed per Tooth (mm) | Depth of Cut (mm) | Coating |

1.0 | 90 | 0.01 | 0.2 | ZrN |

2.0 | 100 | 0.015 | 0.3 | TiN |

3.0 | 80 | 0.02 | 0.4 | AlCrN |

6.0 | 60 | 0.03 | 0.5 | AlCrN |

Common Problems & Solutions

Knowledge of the main problems in dental milling and real-life solutions for overcoming them:

Prevention of Tool Wear

Tool wear is among the biggest worries when machining hard dental alloys such as cobalt-chrome or titanium. Excessive wear can cause poor surface finish, dimension errors, and high tool replacement. To avoid wearing out tools to a minimum:

- Use coated tools (AlCrN, ZrN):AlCrN and ZrN coatings provide resistance to heat and lower the friction between the tool and the material. AlCrN coatings have a temperature strength above 900°C and are suitable for finishing dental crowns at high speeds. ZrN coatings avoid the sticking of material to the cutting edge and the formation of built-up edge when machining sticky alloys.

- Conservative feed rates for finishing:Aggressive feeds during roughing passes may be used, but finishing is best achieved with slower, controlled feeds. This minimizes heat buildup, avoids micro-chipping of the cutting edge, and gives a smooth surface in sensitive crown cavities.

- Replace tools at predetermined intervals:Developing a scheduled replacement by piece count or material hardness prevents sudden tool failure that can destroy expensive dental components. Tool life predictability is ensured by monitoring tool wear through spindle load and surface quality measurements.

- Flute and tip inspection:Routine inspection under magnification or optical measurement detects initial edge rounding, chipping, or coating wear to ensure precise cuts.

Chip Evacuation Optimization

Efficient removal of chips is important in dental CNC machining since chips can fill up deep cavities, scratch surfaces, or cause heat buildup. To improve chip flow:

- Use deep groove end mills or long reach end mills:Deep flute cutters provide sufficient room in which the chips can escape, something that is especially required of long reach end mills for narrow crown or bridge cavities. Well-designed flutes reduce recutting and reduce tool deflection.

- Through-coolant geometries:Through-coolant end mills incorporate internal coolant passages that deliver cutting fluid directly to the cutting edge. Chips are evacuated efficiently and the workpiece and tool are cooled, minimizing heat-induced deformation risk. Dimensions remain accurate and surface finish excellent in dental alloys.

- Trochoidal or spiral toolpaths:Trochoidal milling reduces the tool and material interaction area to a minimum, decreases cutting forces and prevents chip congestion. Spiral or helical paths provide constant chip thickness, which is important for the use of hard dental metals.

- Air blow or high-pressure mist:Where very tight spaces are present, compressed air or mist added helps eliminate very small chips that the coolant cannot flush out.

- Adjust tool step-over and depth of cut:Reducing step-overs on finish passes reduces chip buildup in deep grooves, allowing for smooth surfaces and extending tool life.

Other Considerations

❖ Reduction of vibration and chatter

Deep groove end mills with high rigidity and correct clamping reduce vibration, otherwise resulting in excess tool wear and inferior surface finish.

❖ Material-specific strategies

Titanium alloys give stringy, long chips while cobalt-chrome gives abrading hard chips. Knowing how each one behaves allows you to make feed, speed and flute design changes for better performance.

❖ Maintenance of machine tools

The most critical factor in the prevention of abrupt tool wear or breakage in dental milling is maintaining proper spindle alignment, tight fixturing and uniform coolant flow.

Key Tool Highlights

A brief overview of the main features that make 55HRC deep groove end mills especially ideal for dental prosthetics.

Hardness: 55 HRC for cobalt-chrome and titanium optimized

55 HRC hardness end mills provide a well-balanced combination of hardness and toughness. This keeps the cutting edges sharp when machining hard dental alloys, minimizing the likelihood of chipping and maintaining consistent accuracy for crowns and bridges.

Geometry: Deep flutes for efficient chip removal

Deep groove design makes it possible to remove chips quickly and effectively from thin crown cavities, occlusal surfaces, and bridge connectors. Preventing chips from being recut, these flutes reduce heat generation, enhance surface finish, and minimize the chance of tool breakage when making deep or high-speed cuts.

Coatings: TiN, ZrN, and AlCrN for heat resistance and surface finish

- TiN Titanium Nitride: Lowers friction and the working life of the tool in common dental machining operations.

- ZrN Zirconium Nitride: Prevents built-up edge during cutting sticky materials, particularly cobalt-chrome.

- AlCrN Aluminum Chromium Nitride:Provides superior thermal resistance and is therefore well suited to high-speed or dry machining, retaining sharp edges during extended runs. The coatings also minimize polishing needs, reducing cost and time.

Applications: Crowns, bridges, occlusal surfaces, and fine trimming

These end mills are designed to execute a number of jobs in dental milling:

- Crowns:For roughing and finishing inner cavities with high precision.

- Bridges: Suitable for finishing sensitive connectors and tooth surfaces.

- Occlusal surfaces: Facilitate exact groove milling to design functional tooth morphology.

- Fine trimming: Ideal for small trim adjustments in areas that require a smooth finish.

Tool Types: Long reach end mills and 2 vs 4 flute end mill designs to choose from

Long reach end mills: Used for deep cavities or multi-layer dental components, providing access without sacrificing rigidity.

2 vs 4 Flute End Mill

- 2-flute end mills:Excellent for chip evacuation in confined or intricate forms.

- 4-flute end mills:Give smoother surfaces and minimal scallop marks for high-accuracy applications. Selecting the proper type of flute reconciles cutting efficiency with surface quality.

Further Notables:

- Rigid core design:Resists tool bending and maintains dimensional precision when cutting deep features.

- Feed stability: Enables more aggressive roughing without compromising tool life.

- CNC compatibility with dental machines:Designed for use with contemporary milling centers found in German dental laboratories for consistent, reproducible results.

- Green manufacturing: Several tools are manufactured with environmentally friendly coatings and methods to conserve waste and minimize environmental impact.

Conclusion & Buying Guide

The right deep groove end mills are an investment when it comes to dental prosthetic work. A 55 HRC tool with optimal flute design and coating provides consistent durability, sharp cutting, and always a smooth finish.

Selecting the Best Tool for Dental Material

- Cobalt-Chrome:AlCrN-coated cutters exhibit high heat resistance.

- Titanium:ZrN-coated tools prevent friction and built-up edge.

- Alloys & Soft Ceramics:2-flute TiN-coated tools provide smooth finishing.

Tool Selection Tips and Application

- Use 4-flute tools for high-quality finishing, and 2-flute end mills for improved evacuation of chips.

- Long reach end mills work well in deep crown cavities and dental bridges.

- Choose cutting speed, feed, and depth based on the material to be machined.

- Provide appropriate coolant delivery to prevent overheating and premature tool wear.

Conclusion

The application of 55 HRC deep groove end mills in dental prosthetics demonstrates the direct effect of precision tooling on both quality and efficiency. With the correct hardness, coatings and flute geometry, these tools meet rigorous crown, bridge, and implant requirements with minimal rework and tool change.

By selecting tools based on the dental material involved such as cobalt-chrome, titanium or hybrid ceramics and by applying the correct machining parameters, German medical appliance manufacturers and dental labs can attain repeatable results, long tool life and smooth surface.

For manufacturers who are interested in incorporating these advantages into their operations, HNCarbide provides a reliable source of deep groove end mills, long reach end mills, and precision coated tools tailored for the dental sector. Its product line specializes in the fusion of durability and precision, making it a reliable partner for German manufacturers who emphasize performance, consistency and cost-effectiveness in dental machining.