Why the HM Series End Mills Are the Ultimate Choice for High-Hardness Materials

Machine hardened steels up to 70HRC with HM Series end mills, featuring ultra-fine carbide, advanced coatings, and precision flute design for lasting performance.

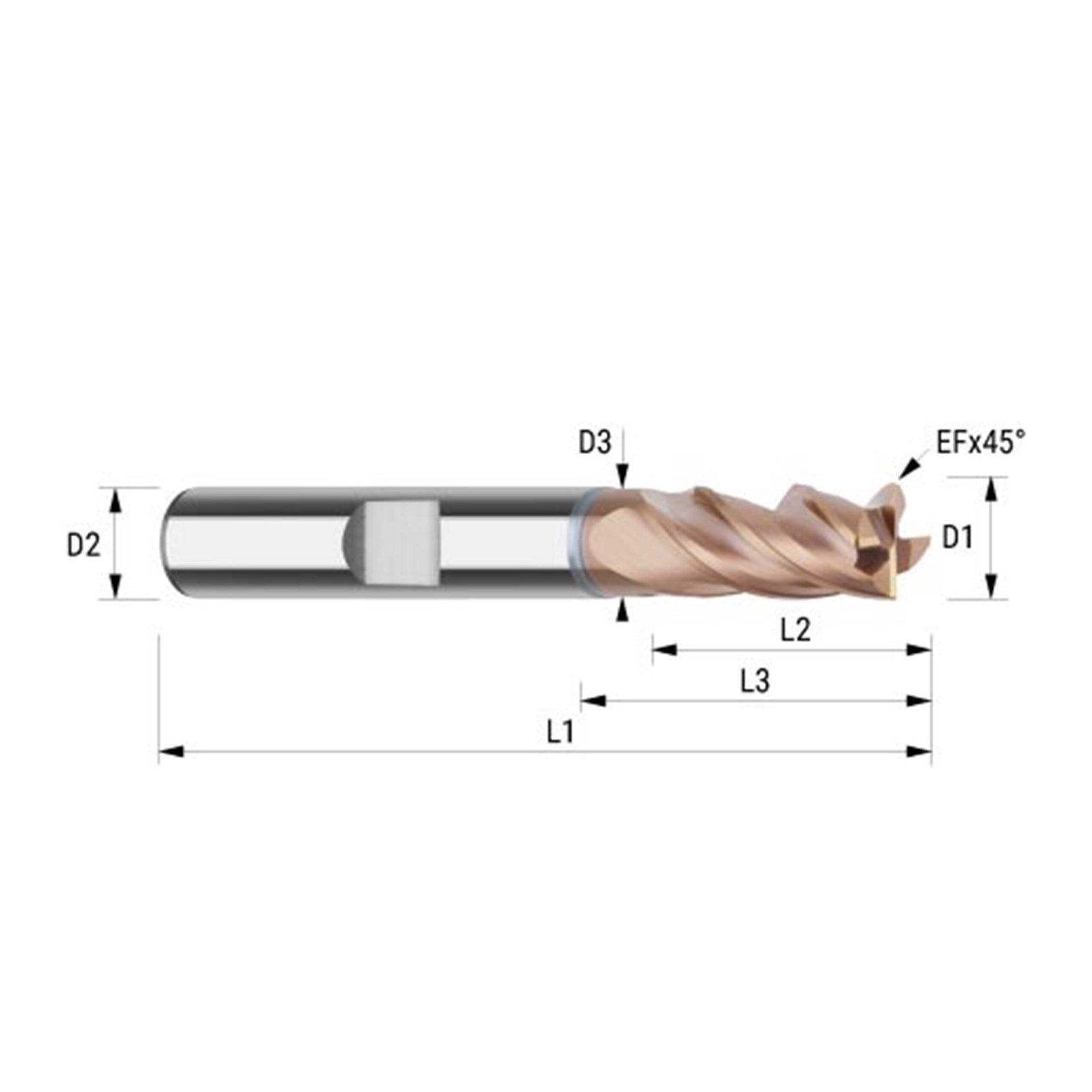

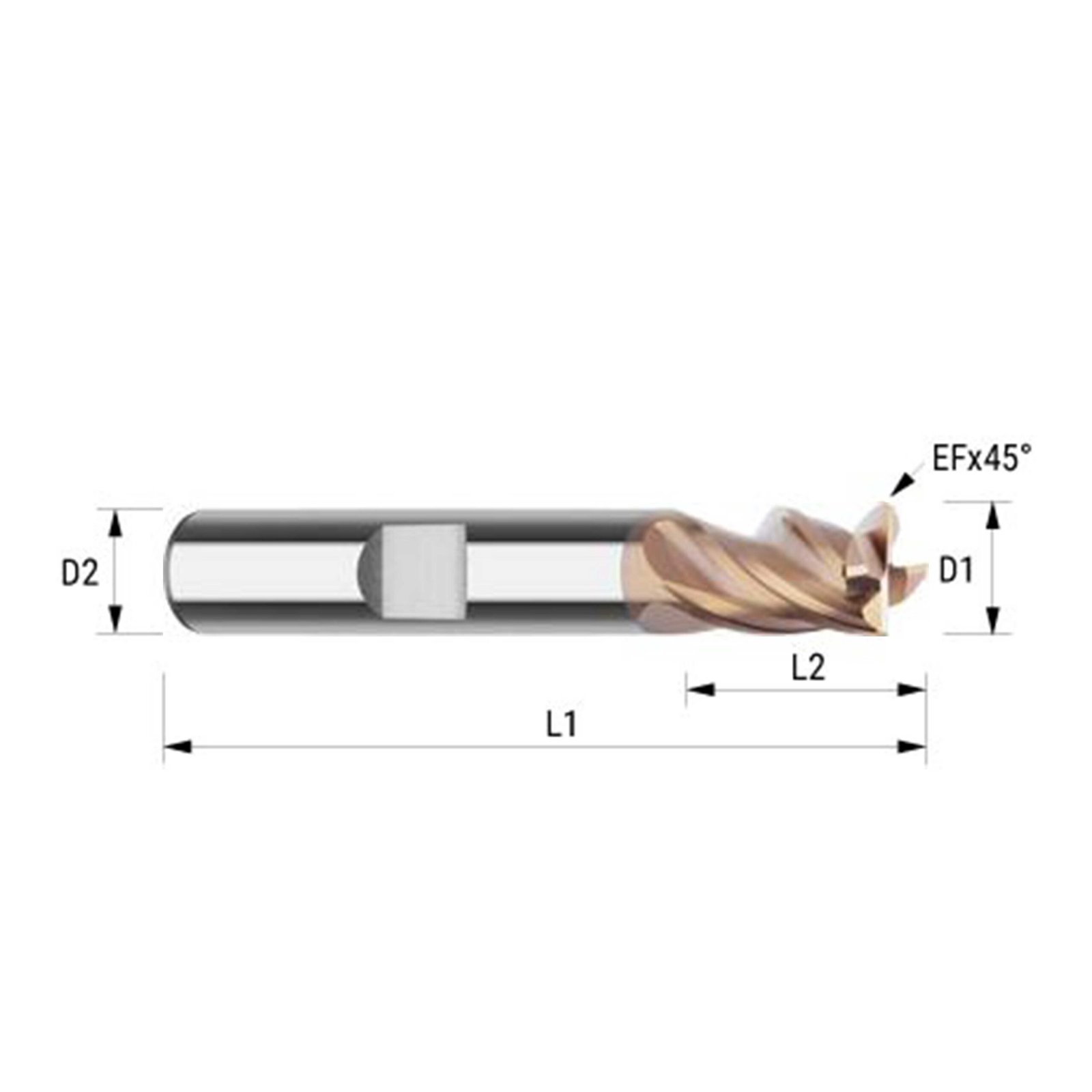

Unequal helix design reduces chatter and vibration

4-flute geometry for smooth cutting and stable chip evacuation

2xD cutting length for versatile milling applications

Square-end profile for precise slotting and contouring

HB shank (Weldon flat) for strong clamping and torque resistance

Solid carbide construction for high wear resistance and tool life

Conforms to DIN standard tolerances

Tool data

Description

This DIN Series GP square end mill is designed with an unequal helix geometry to reduce vibration and chatter, ensuring excellent surface finish and accuracy when machining stainless steel and other tough alloys. With a cutting length of 2xD, it provides versatile performance for standard milling operations.

The 4-flute configuration offers a balance of strength and chip evacuation, making it suitable for both semi-finishing and finishing tasks. The HB shank (Weldon flat) guarantees secure clamping and high torque stability in demanding CNC operations. Manufactured from premium solid carbide and compliant with DIN standards, this tool ensures durability and reliability.

Optimized for stainless steel, alloy steels, and nickel-based alloys

Commonly used in aerospace, medical, automotive, and precision engineering

Ideal for slotting, profiling, contour milling, and finishing

Suitable for high-speed CNC machining environments requiring stability

| Code | Order Number | Coating | Name | Material | Description(dxLcxDxLxT) |

|---|---|---|---|---|---|

| XD4666 | DGS4-2D-030HB | ALCRN | Square End Mill | GU20F | 3x8xH18x6x57xZ4xC0.13 |

| XD4678 | DGS4-2D-040HB | ALCRN | Square End Mill | GU20F | 4x11xH21x6x57xZ4xC0.2 |

| XD4679 | DGS4-2D-050HB | ALCRN | Square End Mill | GU20F | 5x13xH21x6x57xZ4xC0.2 |

| XD4680 | DGS4-2D-060HB | ALCRN | Square End Mill | GU20F | 6x13xH21x6x57xZ4xC0.2 |

| XD4681 | DGS4-2D-080HB | ALCRN | Square End Mill | GU20F | 8x19xH27x8x63xZ4xC0.3 |

| XD4682 | DGS4-2D-100HB | ALCRN | Square End Mill | GU20F | 10x22xH32x10x72xZ4xC0.3 |

| XD4683 | DGS4-2D-120HB | ALCRN | Square End Mill | GU20F | 12x26xH38x12x83xZ4xC0.3 |

| XD4684 | DGS4-2D-140HB | ALCRN | Square End Mill | GU20F | 14x26xH42x14x83xZ4xC0.3 |

| XD4685 | DGS4-2D-160HB | ALCRN | Square End Mill | GU20F | 16x32xH44x16x92xZ4xC0.3 |

| XD4686 | DGS4-2D-180HB | ALCRN | Square End Mill | GU20F | 18x32xH50x18x92xZ4xC0.4 |

| XD4687 | DGS4-2D-200HB | ALCRN | Square End Mill | GU20F | 20x38xH54x20x104xZ4xC0.4 |

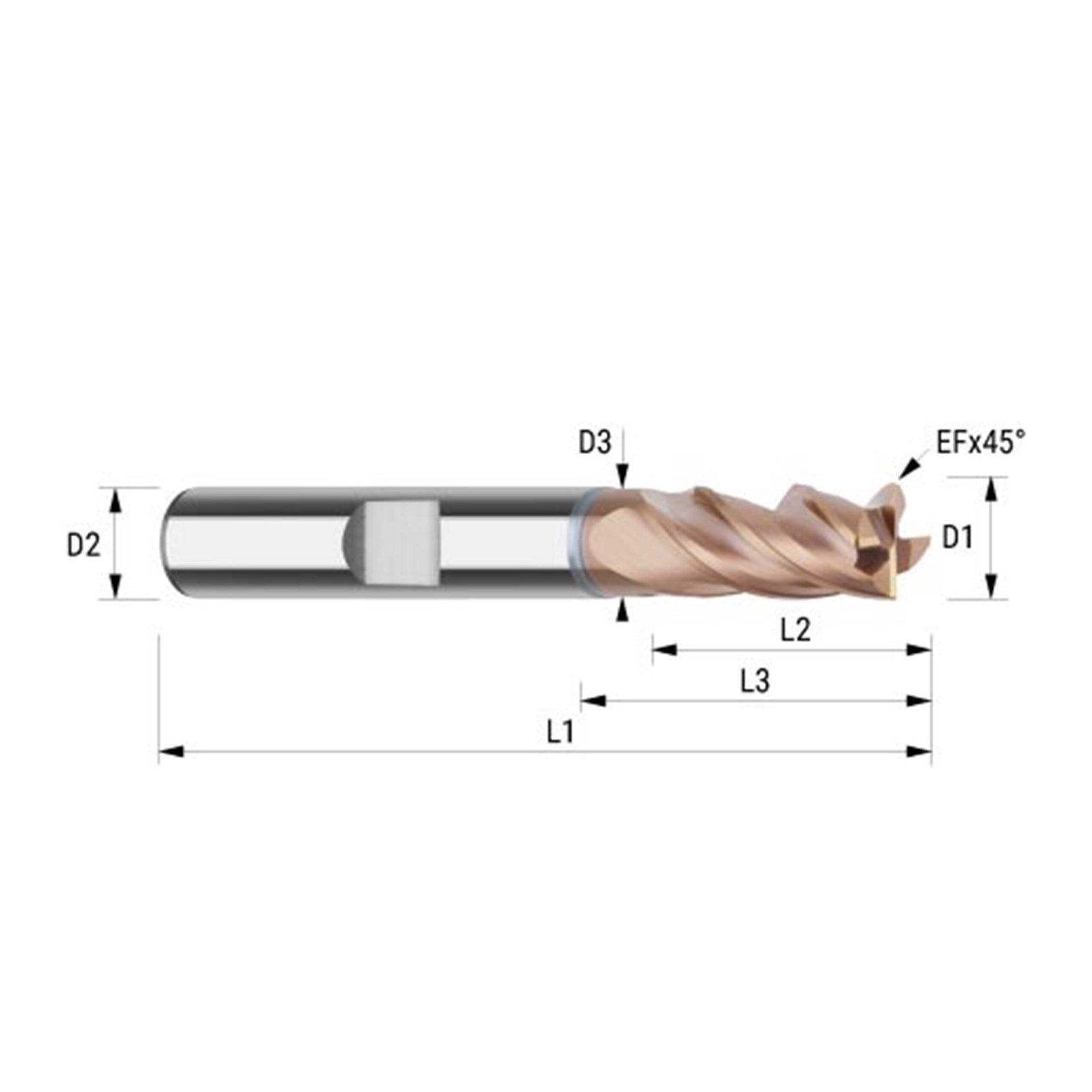

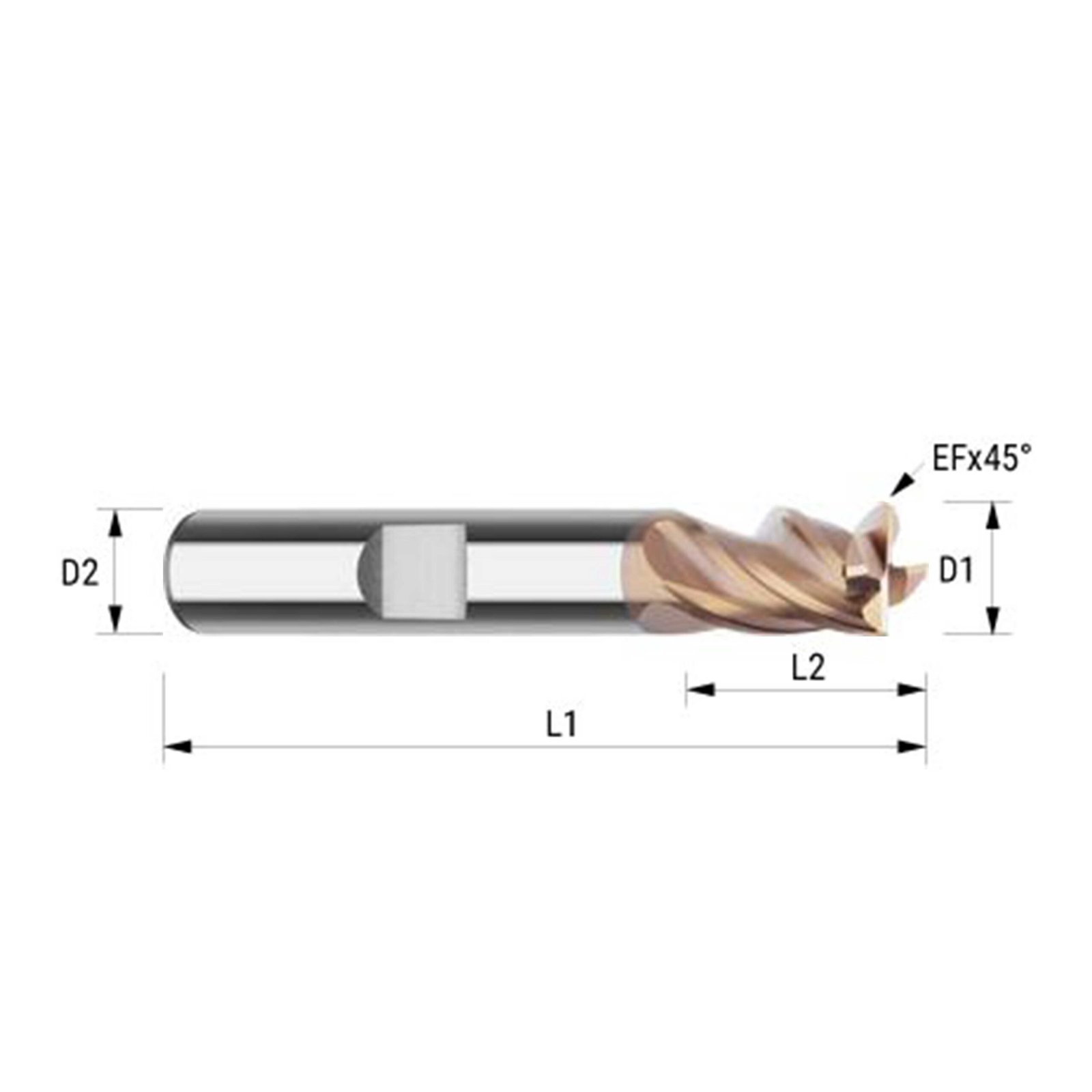

Unequal helix geometry reduces chatter and vibration for smoother cutting

4-flute design offers reliable chip removal and enhanced stability

2xD cutting length for versatile milling tasks

Square-end profile for precise slots, shoulders, and contours

HA shank (straight shank) ensures high concentricity in precision holders

Solid carbide construction for long tool life and wear resistance

Manufactured to DIN standard tolerances

Tool data

Description

This DIN Series GP square end mill is designed with an unequal helix angle to minimize vibration and cutting chatter, ensuring superior surface finish and machining accuracy. With a 2xD cutting length, it provides excellent versatility for both semi-finishing and finishing applications.

The 4-flute geometry balances strength and chip evacuation, while the HA shank (straight shank) delivers high concentricity and secure clamping in precision tool holders such as collets and shrink-fit systems. Made from premium solid carbide and manufactured to DIN standards, this tool ensures durability and consistent performance in stainless steel and other tough alloys.

Optimized for stainless steel, alloy steels, and nickel-based alloys

Commonly used in aerospace, automotive, medical devices, and precision engineering

Suitable for slotting, contouring, profiling, and finishing operations

Ideal for CNC machining centers requiring reduced chatter and stable performance

| Code | Order Number | Coating | Name | Material | Description(dxLcxDxLxT) |

|---|---|---|---|---|---|

| XD4688 | DGS4-2D-030HA | ALCRN | Square End Mill | GU20F | 3x8xH18x6x57xZ4xC0.13 |

| XD4689 | DGS4-2D-040HA | ALCRN | Square End Mill | GU20F | 4x11xH21x6x57xZ4xC0.2 |

| XD4690 | DGS4-2D-050HA | ALCRN | Square End Mill | GU20F | 5x13xH21x6x57xZ4xC0.2 |

| XD4691 | DGS4-2D-060HA | ALCRN | Square End Mill | GU20F | 6x13xH21x6x57xZ4xC0.2 |

| XD4692 | DGS4-2D-080HA | ALCRN | Square End Mill | GU20F | 8x19xH27x8x63xZ4xC0.3 |

| XD4693 | DGS4-2D-100HA | ALCRN | Square End Mill | GU20F | 10x22xH32x10x72xZ4xC0.3 |

| XD4694 | DGS4-2D-120HA | ALCRN | Square End Mill | GU20F | 12x26xH38x12x83xZ4xC0.3 |

| XD4695 | DGS4-2D-140HA | ALCRN | Square End Mill | GU20F | 14x26xH42x14x83xZ4xC0.3 |

| XD4696 | DGS4-2D-160HA | ALCRN | Square End Mill | GU20F | 16x32xH44x16x92xZ4xC0.3 |

| XD4697 | DGS4-2D-180HA | ALCRN | Square End Mill | GU20F | 18x32xH50x18x92xZ4xC0.4 |

| XD4698 | DGS4-2D-200HA | ALCRN | Square End Mill | GU20F | 20x38xH54x20x104xZ4xC0.4 |

Unequal helix geometry reduces chatter and vibration for smoother cutting

4-flute design offers reliable chip removal and enhanced stability

2xD cutting length for versatile milling tasks

Square-end profile for precise slots, shoulders, and contours

HA shank (straight shank) ensures high concentricity in precision holders

Solid carbide construction for long tool life and wear resistance

Manufactured to DIN standard tolerances

Tool data

Description

This DIN Series GP square end mill is designed with an unequal helix angle to minimize vibration and cutting chatter, ensuring superior surface finish and machining accuracy. With a 2xD cutting length, it provides excellent versatility for both semi-finishing and finishing applications.

The 4-flute geometry balances strength and chip evacuation, while the HA shank (straight shank) delivers high concentricity and secure clamping in precision tool holders such as collets and shrink-fit systems. Made from premium solid carbide and manufactured to DIN standards, this tool ensures durability and consistent performance in stainless steel and other tough alloys.

Optimized for stainless steel, alloy steels, and nickel-based alloys

Commonly used in aerospace, automotive, medical devices, and precision engineering

Suitable for slotting, contouring, profiling, and finishing operations

Ideal for CNC machining centers requiring reduced chatter and stable performance

| Code | Order Number | Coating | Name | Material | Description(dxLcxDxLxT) |

|---|---|---|---|---|---|

| XD4787 | DGS4-3D-060HB | ALCRN | Square End Mill | GU20F | 6x22xH30x6x63xZ4xC0.2 |

| XD4788 | DGS4-3D-080HB | ALCRN | Square End Mill | GU20F | 8x28xH36x8x80xZ4xC0.2 |

| XD4789 | DGS4-3D-100HB | ALCRN | Square End Mill | GU20F | 10x33xH54x10x100xZ4xC0.2 |

| XD4790 | DGS4-3D-120HB | ALCRN | Square End Mill | GU20F | 12x42xH54x12x100xZ4xC0.3 |

| XD4791 | DGS4-3D-160HB | ALCRN | Square End Mill | GU20F | 16x53xH69x16x150xZ4xC0.3 |

| XD4792 | DGS4-3D-200HB | ALCRN | Square End Mill | GU20F | 20x68xH84x20x150xZ4xC0.4 |

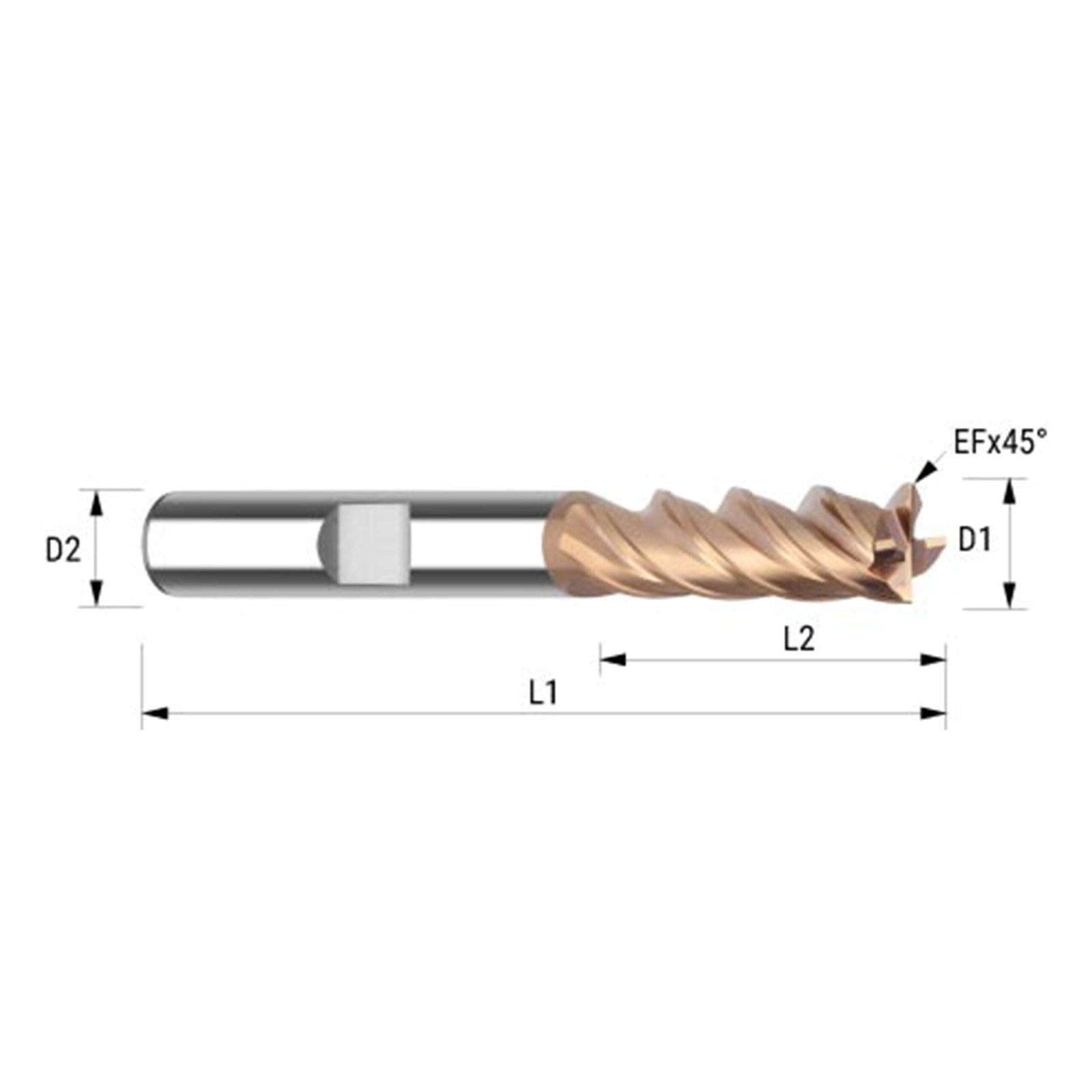

Unequal helix geometry reduces vibration and improves stability

4-flute design provides smooth cutting and stable chip flow

3xD cutting length for extended reach and versatility

Square-end profile for accurate slotting, shoulder milling, and contouring

HA shank (straight shank) ensures high concentricity and precise clamping

Premium solid carbide construction for long tool life

Produced according to DIN standard tolerances

Tool data

Description

This DIN Series GP square end mill is engineered with an unequal helix design to suppress vibration and chatter, ensuring improved machining stability and excellent surface finish. With a 3xD cutting length, it provides extended reach for a wide range of milling applications.

The 4-flute geometry balances tool strength with efficient chip evacuation, making it well-suited for semi-finishing and finishing operations. Featuring a HA shank (straight shank), the tool delivers superior concentricity and is compatible with precision collet and shrink-fit holders. Manufactured from premium solid carbide and conforming to DIN standards, this cutter ensures reliability and durability in stainless steel and other challenging materials.

Optimized for stainless steel, alloy steels, and nickel-based alloys

Widely used in aerospace, medical, automotive, and precision engineering

Suitable for slotting, profiling, contour milling, and finishing operations

Designed for high-speed CNC machining requiring reduced chatter

| Code | Order Number | Coating | Name | Material | Description(dxLcxDxLxT) |

|---|---|---|---|---|---|

| XD4793 | DGS4-3D-060HA | ALCRN | Square End Mill | GU20F | 6x22xH30x6x63xZ4xC0.2 |

| XD4794 | DGS4-3D-080HA | ALCRN | Square End Mill | GU20F | 8x28xH36x8x80xZ4xC0.2 |

| XD4795 | DGS4-3D-100HA | ALCRN | Square End Mill | GU20F | 10x33xH54x10x100xZ4xC0.2 |

| XD4796 | DGS4-3D-120HA | ALCRN | Square End Mill | GU20F | 12x42xH54x12x100xZ4xC0.3 |

| XD4797 | DGS4-3D-160HA | ALCRN | Square End Mill | GU20F | 16x53xH69x16x150xZ4xC0.3 |

| XD4798 | DGS4-3D-200HA | ALCRN | Square End Mill | GU20F | 20x68xH84x20x150xZ4xC0.4 |

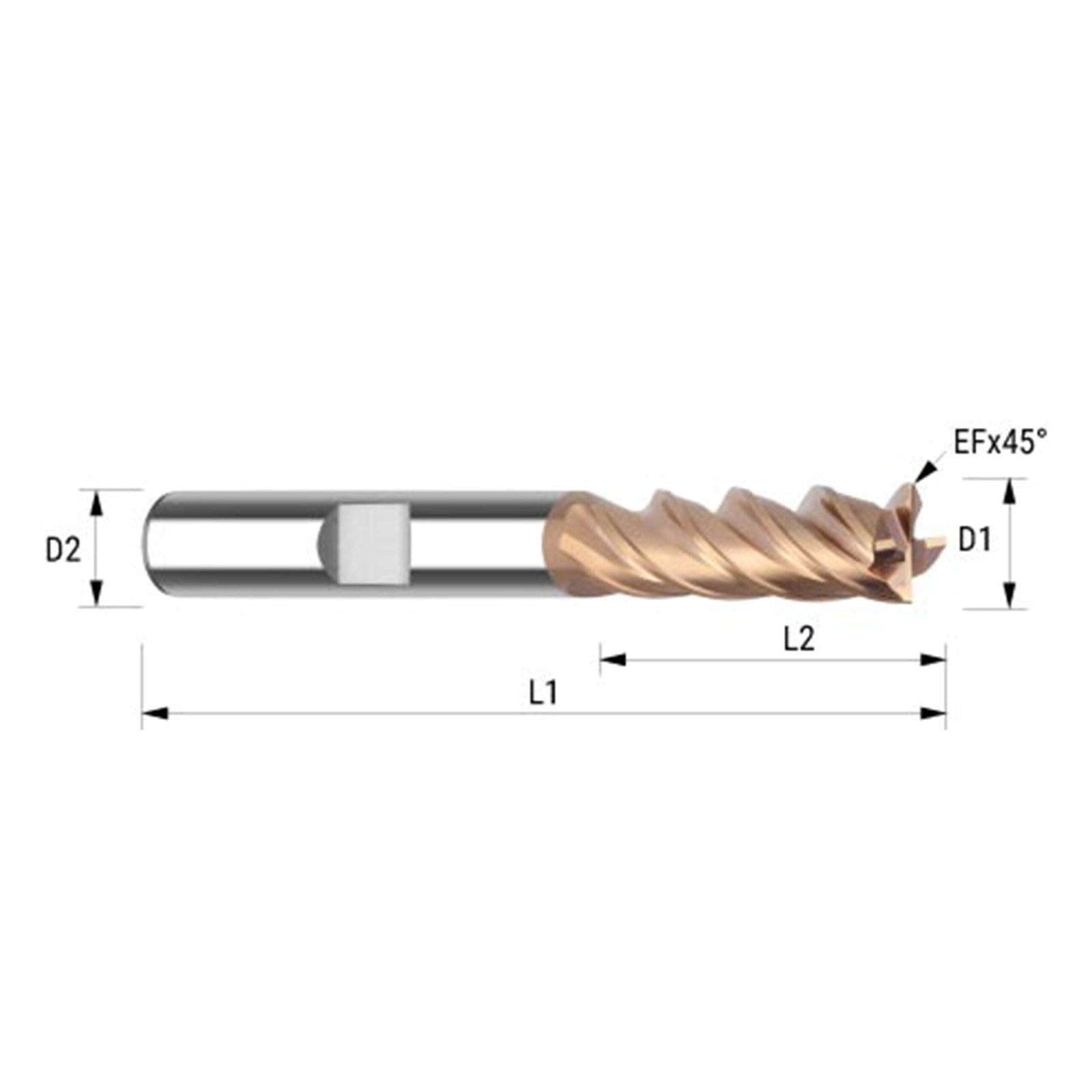

Unequal helix geometry minimizes chatter and enhances accuracy

4-flute design for balanced strength and smooth chip flow

1xD cutting length for short, rigid, and precise milling applications

Square-end profile for accurate slotting, shoulders, and contouring

HB shank (Weldon flat) ensures secure clamping and torque resistance

Solid carbide construction for excellent wear resistance

Complies with DIN standard tolerances

Tool data

Description

This DIN Series GP square end mill is designed with an unequal helix angle to reduce chatter and vibration, ensuring stable cutting and improved surface quality. With a 1xD cutting length, it is optimized for short-reach milling tasks requiring rigidity and precision.

The 4-flute geometry balances cutting performance and chip evacuation, while the HB shank (Weldon flat) provides strong clamping security and high torque resistance. Manufactured from premium solid carbide and compliant with DIN standards, this cutter ensures durability and reliability in machining stainless steel and other difficult materials.

Specifically designed for stainless steel, alloy steels, and nickel-based alloys

Common in aerospace, medical, automotive, and precision engineering

Ideal for slotting, contouring, and finishing where high rigidity is needed

Suitable for CNC machining centers under stable setups

| Code | Order Number | Coating | Name | Material | Description(dxLcxDxLxT) |

|---|---|---|---|---|---|

| XD4799 | DGS4-1D-030HB | ALCRN | Square End Mill | GU20F | 3x6x6x54xZ4xC0.1 |

| XD4800 | DGS4-1D-040HB | ALCRN | Square End Mill | GU20F | 4x8x6x54xZ4xC0.13 |

| XD4801 | DGS4-1D-050HB | ALCRN | Square End Mill | GU20F | 5x9x6x54xZ4xC0.18 |

| XD4802 | DGS4-1D-060HB | ALCRN | Square End Mill | GU20F | 6x10x6x54xZ4xC0.2 |

| XD4803 | DGS4-1D-080HB | ALCRN | Square End Mill | GU20F | 8x12x8x58xZ4xC0.2 |

| XD4804 | DGS4-1D-100HB | ALCRN | Square End Mill | GU20F | 10x14x10x66xZ4xC0.2 |

| XD4805 | DGS4-1D-120HB | ALCRN | Square End Mill | GU20F | 12x16x12x73xZ4xC0.3 |

| XD4806 | DGS4-1D-140HB | ALCRN | Square End Mill | GU20F | 14x18x14x75xZ4xC0.3 |

| XD4807 | DGS4-1D-160HB | ALCRN | Square End Mill | GU20F | 16x22x16x82xZ4xC0.3 |

| XD4808 | DGS4-1D-180HB | ALCRN | Square End Mill | GU20F | 18x24x18x84xZ4xC0.4 |

| XD4809 | DGS4-1D-200HB | ALCRN | Square End Mill | GU20F | 20x26x20x92xZ4xC0.4 |

Unequal helix design reduces chatter and vibration for stable machining

4-flute configuration ensures efficient cutting and smooth chip evacuation

1xD cutting length for maximum rigidity and precision in short cuts

Square-end profile for accurate shoulders, slots, and contours

HA straight shank ensures high concentricity in precision holders

Made from solid carbide for excellent wear and heat resistance

Manufactured to DIN standard tolerances

Tool data

Description

This DIN Series GP square end mill is designed with an unequal helix angle to suppress vibration and cutting chatter, ensuring smooth machining and excellent surface finish. With a 1xD cutting length, it provides superior rigidity and precision for short-reach milling operations.

The 4-flute geometry delivers balanced performance in strength and chip evacuation, making it suitable for semi-finishing and finishing. The HA shank (straight shank) provides high concentricity and is compatible with precision tool holders such as collet and shrink-fit systems. Produced from premium solid carbide and conforming to DIN standards, this tool guarantees accuracy, stability, and durability in stainless steel and other challenging alloys.

Optimized for stainless steel, alloy steels, and nickel-based alloys

Widely applied in aerospace, automotive, medical devices, and precision machining

Suitable for slotting, contouring, and finishing operations requiring high rigidity

Designed for CNC machining centers where low vibration is critical

| Code | Order Number | Coating | Name | Material | Description(dxLcxDxLxT) |

|---|---|---|---|---|---|

| XD4810 | DGS4-1D-030HA | ALCRN | Square End Mill | GU20F | 3x6x6x54xZ4xC0.1 |

| XD4811 | DGS4-1D-040HA | ALCRN | Square End Mill | GU20F | 4x8x6x54xZ4xC0.13 |

| XD4812 | DGS4-1D-050HA | ALCRN | Square End Mill | GU20F | 5x9x6x54xZ4xC0.18 |

| XD4813 | DGS4-1D-060HA | ALCRN | Square End Mill | GU20F | 6x10x6x54xZ4xC0.2 |

| XD4814 | DGS4-1D-080HA | ALCRN | Square End Mill | GU20F | 8x12x8x58xZ4xC0.2 |

| XD4815 | DGS4-1D-100HA | ALCRN | Square End Mill | GU20F | 10x14x10x66xZ4xC0.2 |

| XD4816 | DGS4-1D-120HA | ALCRN | Square End Mill | GU20F | 12x16x12x73xZ4xC0.3 |

| XD4817 | DGS4-1D-140HA | ALCRN | Square End Mill | GU20F | 14x18x14x75xZ4xC0.3 |

| XD4818 | DGS4-1D-160HA | ALCRN | Square End Mill | GU20F | 16x22x16x82xZ4xC0.3 |

| XD4819 | DGS4-1D-180HA | ALCRN | Square End Mill | GU20F | 18x24x18x84xZ4xC0.4 |

| XD4820 | DGS4-1D-200HA | ALCRN | Square End Mill | GU20F | 20x26x20x92xZ4xC0.4 |

Machine hardened steels up to 70HRC with HM Series end mills, featuring ultra-fine carbide, advanced coatings, and precision flute design for lasting performance.

Explore why DIN standard & ball carbide end mills deliver precision, durability & CNC compatibility for aerospace, automotive, mold and medical manufacturing.

Discover what’s driving tungsten carbide price hikes in 2025 and how European toolmakers can respond with smart sourcing, recycling, and tool upgrades.

WhatsApp us

Before you go, please note that we offer the most up-to-date industry research reports and the most comprehensive product catalogs, so please contact us if you are interested!

Before you go, please note that we offer the most up-to-date industry research reports and the most comprehensive product catalogs, so please contact us if you are interested!