Precision Milling of Stainless Steel: The Perfect Choice for Cutting Force Optimization

Table of Contents

Precision milling is a key manufacturing process used across various industries to produce high-quality stainless steel components with tight tolerances. This advanced CNC machining technique enables the creation of complex geometries and features on stainless steel workpieces, leveraging the material’s strength and corrosion resistance.

Lets have a discussion in details !

What is Stainless Steel Milling

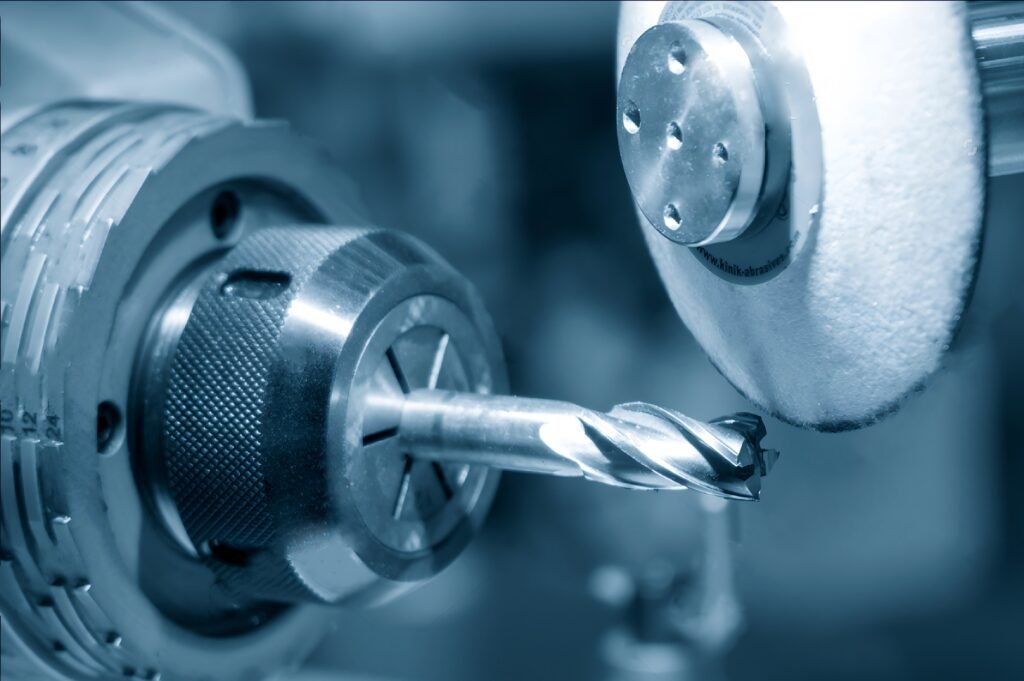

Stainless steel milling refers to the precision cutting of stainless steel materials using computer numerical control (CNC) milling machines and carbide or high speed steel milling cutters. It is an extremely common secondary machining process employed globally to manufacture critical stainless steel components with high dimensional accuracy and optimal surface finish.

Milling cutters are rotary cutting tools that remove material from stainless steel workpieces on CNC milling machines, which offer multi-axis movements under computerized control. Milling operations involve the use of sharp milling cutters bits to literally carve out parts by progressively shaving off layers of metal in small chip loads.

Applications Where Stainless Steel Milling is Commonly Used

Milling is overwhelmingly the most common machining technique used to fabricate stainless steel components across practically every industry, including:

- Aerospace: Structural brackets, engine components, landing gear parts

- Medical: Surgical instruments, implants, hospital equipment

- Food and pharmaceutical equipment: Tanks, valves, fittings, mixers

- Chemical processing: Pumps, manifolds, housings, vessels

- Oil and gas: Wellhead parts, compressors, drill equipment

- Fasteners and housings: For the automotive, appliance and electronic sectors

Benefits of Stainless Steel as a Material

Stainless steel is valued tremendously as a precision milling material due to its many inherent advantages, including:

- Extreme corrosion resistance, including in harsh environments

- High strength-to-weight ratio compared to other metals

- Excellent high temperature properties up to 1000°C

- Sturdy mechanical durability and impact resistance

- Manufacturability using a wide range of methods like milling

- Ability to be cleaned, sterilized and reused safely

- 100% recyclability for sustainability

Types of Stainless Steel and Their Properties

With over 150 grades, stainless steels have diverse compositions optimized for various operating conditions. The right stainless alloy and treatment must be selected when CNC milling parts in order to leverage the full capabilities of this material.

1. Austenitic Stainless Steels

Austenitic stainless steels constitute over 70% of total stainless production due to their excellent formability and weldability. They contain significant nickel and manganese to produce a non-magnetic austenite crystal structure.

Most Common Austenitic Grades Used

The austenitic grades most frequently milled include:

- 304/304L – The most popular and cost-effective grade by far. Also called 18/8 or A2 stainless, with 18% chromium and 8% nickel.

- 316/316L – The second most common grade. Also called marine grade or A4 stainless, with the addition of 2-3% molybdenum for increased corrosion resistance.

- 303 – A free-machining variant of 304 with added sulfur for improved machinability.

- 321 – A titanium-stabilized 304 variant for improved high temperature strength.

2. Ferritic Stainless Steels

Ferritic stainless steels contain 12-30% chromium with low or no nickel content, giving them a magnetic body centered cubic (BCC) iron crystal organization. They offer moderate formability and excellent resistance to stress corrosion cracking.

Common Ferritic Grades

The primary ferritic grades used include:

- 409/409L – The most widely used ferritic grade, commonly stocked in coil or sheet forms to minimize availability issues.

- 430 – The basic chromium ferritic grade with relatively inferior corrosion resistance.

- 446 – With further chromium and titanium/niobium additions for enhanced mechanical properties and improved oxidation resistance.

3. Martensitic Stainless Steels

Containing 11-18% chromium with very low nickel content, martensitic stainless steels possess a hard, magnetic BCC crystal lattice that can be heat treated for enhanced hardness and strength for cutlery or aerospace applications.

Martensitic Grades

Common milled martensitic grades incorporate:

- 420/420F – The baseline, general purpose chromium steel without nickel additions. Often used for surgical tools due to good corrosion resistance and ability to be precision ground.

- 440A/B/C – Higher carbon grades than 420, with increasing hardness in the sequence A/B/C. Used for razor blades, cutlery knives, scissors, hand tools and bearings where hardness is critical.

4. Duplex Stainless Steels

As the name indicates, duplex stainless steels have a mixed microstructure containing both austenite and ferrite phases. They were designed to offer superior strength and stress corrosion cracking resistance than either phase by itself.

Common variants involve:

- 2205 – The most widely used grade with 22% chromium, 5% nickel and 3% molybdenum. Presents high yield strength double that of 304/304L.

- 2507 – Significantly higher strength than 2205, with 25% chromium, 7% nickel, 4% molybdenum and lower carbon. Requires nitrogen control when welding.

- Zeron 100 – A super duplex variant with very high strength plus over 25% chromium for exceptional corrosion resistance in aggressive environments including acids.

Milling Tools for Stainless Steel

Proper tooling selection helps stainless steel milling by enabling efficient material removal while minimizing undesirable work hardening, built up edge, gummy chips, excessive forces and tool wear or breakage.

Carbide End Mills

Solid carbide end mills represent the most common tool type for the majority of stainless milling tasks. They are made from fine-grained tungsten carbide (WC) forming the Solid carbide milling cutter body, which is then coated and sharpened.

Grades Optimized for Stainless

Carbide grades developed specifically for stainless incorporate:

- Micrograin substrates with cobalt levels between 10-12% to balance strength, hardness and impact resistance

- Sub-micron carbides and uniform distribution for strength and durability

- High edge toughness and compression strength to withstand interrupted cuts

Common examples are the BF100, BF1000 and BF1500 grades uniquely formulated to enable stainless steel milling productivity.

Design Considerations

Ideal tool geometries for stainless jobs encompass:

- High positive rake angles around 24° to slice efficiently

- Polished flutes to prevent material adhesion

- Eccentric relief for enhanced edge strength

- Variable helix flutes to reduce harmonics and peak loads

- Necked tools for long reach or deep cavity accessibility

3 flute designs offer excellent stability and chip evacuation capability. 4 flute is also popular for improved surface finish on profiling operations if deflection is not an issue.

Coatings

Protective TiAlN-based coatings prolong carbide life by reducing heat and friction at the cutting interface on stainless alloys. More advanced variations like aluminum titanium nitride (AlTiN) and silicon aluminum titanium nitride (SiAlTiN) offer:

- Significantly higher operating temperatures tolerance before diffusion or oxidization

- Excellent abrasion resistance to mitigate built up edge and scoring

- Low thermal conductivity for less transferred heat

- Facilitated chip flow off the cutting face

These coatings enhance speed, feed rate, tool life and part quality dramatically on gummy or abrasive stainless materials during milling.

High Speed Steel Tools

While more productivity focused carbide tooling is overwhelmingly prevalent today, high speed steel (HSS) end mills retain usefulness for certain difficult stainless milling tasks.

When HSS Tools Make Sense

Reasons to utilize HSS tools encompass:

- Interrupted cuts or repetitive tool load shocks that quickly fracture carbide

- Extremely high material hardness nearing the tool’s capabilities

- Difficult set ups restricting rigidity or requiring slim tools

- Very small part feature details or internal radii

- Limited production runs not warranting carbide investment

In these scenarios, HSS’s inherent strength, resilience and sharpenability provides a cost-effective option over carbides.

Tool Life Challenges

However, HSS limitations must also be recognized, requiring awareness around:

- Lower hardness and wear resistance than carbide, limiting speeds/feeds

- Higher friction and temperatures weakening tools over time

- Propensity for built up edge and abrasive wear on tool face and flanks

- Resharpening difficulties presented by complex end mill geometries

While situationally useful despite lower performance, HSS tooling requires extra expertise to leverage effectively long-term on stainless.

Indexable/Insert Milling Tooling

For high efficiency material removal, indexable face mills with removable carbide inserts enable stainless milling productivity with economical operating costs.

Benefits of Indexable Mills

Reasons shops utilize indexable tooling encompass:

- Cost efficiency via interchangeable inserts vs. solid tools

- Ability to index to fresh cutting edges preventing tool changeovers

- Customized cutting action from extensive insert geometries/materials/coatings

- Flexible and simple insert replacements with minimal adjustment needs

- Large depth of cuts, widths and metal removal rates

These attributes maximize uptime and lower machining expenses.

Insert Grades and Geometries

Inserts specifically for stainless come in grades like HC500 and HC700 plus GC400 series. HC700 for example combines:

- Micrograin tungsten carbide substrate for strength

- High edge toughness and hardness up to 1600 HV for abrasion resistance

- Specialized geometry including axial rake angles, edge preps and chips splitters

- Polished rake faces to mitigate material sticking

- Reduced contact area to limit friction and cutting temperatures

Meanwhile, insert shapes range from squares/triangles for light to medium milling to 80° rhombic for more demanding heavy roughing at high speeds and feeds.

Proper grade and insert profiles align with cutter body design for targeted stainless milling functionality.

Tool Selection Guidelines

An informed approach helps ensure the most appropriate tools get picked based on variables like operation, workpiece properties, tolerances and runtime.

Roughing vs Finishing Considerations

Roughing works best with:

- More aggressive tool geometries and sharp cutting edges

- Positive rakes over 20° to shear efficiently

- Light radial depth cuts under 25% cutter diameter

- Higher feed rates possible with deeper axial depths

- TiAlN type coatings for high speed stability

Finishing prefers:

- Sharp tools with polished flutes and tight edge radii

- Lower rakes around 15° for smoother low-load cutting

- Very light depths of cut and stepovers

- Lower/interrupted feeds to avoid chatter or deflection

- Uncoated or fine grained carbide for superior finish

Best Practices for Machining Stainless Steel

Certain methods substantially boost stainless milling efficiency, tool life and workpiece quality when applied appropriately.

Cutting Parameters

The optimal speed and feed inputs depend heavily on work material, tool profiles, depths of cut and desired surface finish.

Speeds and Feeds

- Typical rpm ranges for roughing vary from 100-350 SFM (30-107 m/min) based on cutter diameter

- Finish milling drops to 75-200 SFM (23-61 m/min) for better accuracy and control

- Coated solid carbide enables 50% higher feeds than HSS tools

- Chip thinning considerations guide axial and radial depths of cut

- Light finish passes should use feed rates under 10 IPM (.25 m/min)

These starting points help maximize material removal rates based on tooling capabilities.

Depth of Cut

Conservative depth of cut guidelines include:

- Roughing works best at <25% cutter diameter radial passes

- Axial cutting depths up to 2-3x cutter diameter are possible

- Finish milling works best <15 IPM (.4 m/min) axial

- Stepdown to <5% cutter diameter during final pass

Deeper cuts risk tool failure, work hardening or poor finish quality on stainless.

Use of Coolants/Lubricants

Cutting fluids deter the troublesome heat and friction stainless alloys generate during milling.

Wet vs Dry Cutting Considerations

When it comes to wet versus dry cutting, flood coolant offers the maximum heat and chip flushing, but the mess it creates requires cleanup while risking workpiece contamination. As an alternative, minimum quantity lubrication (MQL) mists utilize a fraction of the liquid volume, thereby reducing the downsides of flood methods.

For light cuts under 50 SFM (15 m/min), dry cutting is possible with some of the advanced tool coatings available now. In particular, specialized additives like Micro-G Sr ionized oil have been proven to combat built up edge and extend tool life by up to 300% when milling stainless steel dry. At higher cutting speeds, jet stream air cooling can also help disrupt chip wrap on the tool while preventing thermal cracks on the exposed cut surfaces.

Thorough cost/benefit analysis steering appropriate coolant minimizes milling headaches.

Types of Fluids

Common alternatives encompass:

- Soluble oils for general stainless milling, using 5-10% concentration ratio with water

- Synthetics like polyalkylene glycol offering superior lubricity and resisting rancidity

- Semi-synthetics combining soluble oil and synthetic benefits

- Vegetable oil micro-mists possible, but limited effectiveness and messy

- Supercritical CO2 shows promise for clean, waste-free “coolant” under pressure

Fixture and Workholding Considerations

Secure fixturing ensures milling process stability, while inappropriate work holding introduces problematic chatter, tool wear, poor finish and scrap parts.

Proper fixturing requires minimizing overhang through correct end mill lengths, eliminating any ability for workpiece movement under load, avoiding unsupported bending spans, rigid clamping on vibration-damping mounts, strong vise jaws gripping evenly, fully indicating parts square and flat, and utilizing ball/strap/modular clamps spreading forces evenly. Any flexibility reduces precision and control when cutting stainless steel.

Thin parts risk plastically deforming or warping under forces and localized heating, along with cracking upon unclamping. Thermal issues also risk annealing regions and losing hardness while enabling grain boundary corrosion. Proper coolant use, conservative stepdowns, cut planning and post-process stress relief counteract part instability.

Machine Tool Requirements

Milling equipment directly impacts key performance attributes for stainless fabrication, including accuracy, surface finish, tool life and overall productivity.

Adequate stainless steel milling requires 15 horsepower for heavy cuts, high torque spindles enabling rapid accel/decel without stalling, BT/ISO 30-40 taper toolholders balancing rigidity and diversity, and 10,000+ RPM capabilities for small cutters and finishing. Robust electrical and mechanical prowess enables full stainless potential.

Necessities include over 20 tons of supporting force, box guideways/torque tubes/monoblock construction, heavy mounting components, vibration-isolated dampened mounts, and enough mass for dynamic stability at higher feeds. Massive components not deflecting under heavy stainless loads maintain precision tight.

Force Modeling and Monitoring

Predicting and controlling cutting forces enables optimizing stainless milling efficiency through adaptive techniques while preventing mechanical failures.

Cutting Forces Explained

The tangential (power requirement) and radial (machining vibration source) forces arise primarily from shearing the material itself and secondarily from friction along the tool’s rake face.

Milling forces arise primarily from shearing the material and secondarily from friction along the cutter’s rake. The tangential force (FT) provides the power requirement to machine, acting perpendicular to the cutter edge. The radial force (FR) introduces vibrations, pushing laterally on the tool and workpiece. Careful analysis and control of these vectors is critical for optimization.

The tangential “power” force overcoming shear strength results from work material hardness, cut widths and depths, feeds determining cut area, and tool geometry. Radial forces derive from rake/flank friction, pressures and temperatures, edge radius size, and workpiece properties. Magnitude risks chatter and accuracy loss. Monitoring and adapting based on these vectors boosts efficiency.

Monitoring Cutting Forces

Shop examples now use instrumented spindles, machine mounts and robotic load cells to chart measured cutting forces in real time, while software estimates forces for any given set of operating inputs.

Dynamometers and Sensors

- Machine table or spindle mounts with built-in piezoelectric load cells directly quantify loading

- Wireless Bluetooth torque sensor modules bolt to spindle housing for strain measurement

- Turning stick tools with multiple strain gages near the cutting tip provide force directionality

- High sample rate data affects real-time feed/speed rate adjustment

Software Simulation/Estimation

- Physics-based models can predict tool/workpiece forces based on programmed toolpath

- Model inputs include material data, tooling details, cut regions and operating parameters

- Some CAM packages now integrate force approximation to guide toolpath strategies

Comparison with real measurements enables accurate force picture.

Effects of Excessive Cutting Forces

Potential stainless milling repercussions span:

- Accelerated tool wear, fracture or insert breakout

- Chatter marks or wavy finish issues

- Machine overload risks impeding motion

- Workpiece deformation errors

- Unstable process lowering productivity

Careful operation inside equipment thresholds prevents damage.

Optimizing Based On Cutting Forces

“Force-based machining” leverages sensors and software to actively balance material removal rate, accuracy and tool longevity via inputs like:

- Real-time feed rate modulation to sustain safe force thresholds

- Spindle speed variance to optimize shear angle and lower forces

- Axial/radial depth adjustments staying within stability bands

- Toolpath tool/flute sequencing to spread load

The future of smart machining lies in automated dynamic optimization rather than just “set and forget” practices.

Optimizing Stainless Steel Machining

Huana Tools brings over 15 years of focused cutting tool expertise catering to stainless steel and other challenging materials. As an international supplier, we provide carbide and HSS solutions personalized for individual machining needs across industries like aerospace, medical, chemical, oil and gas.

Precision Tooling Targeting Stainless Performance

Our extensive catalog encompasses specialized end mills, drills, thread mills, engravers and inserts purpose-built for reliability. This includes precision carbide grades and geometries like variable helix/necked mills, high positive rake cutters, polished flutes, advanced coatings, rhombic CCMT inserts and more proven on stainless.

Customization and Quick Delivery

Besides standard inventory, we also customize tools based on your exact alloy, tolerances, operations and machine parameters for superior performance. Swift manufacturing and shipment gets products delivered fast while our engineers support application optimization.

Future Outlook for Stainless Machining

Industry 4.0 connectivity, AI-enhanced software and smarter machine tools will together transform stainless capabilities further through:

- Seamless CAD/CAM/CNC digital thread chain implementation

- Intelligent simulation guiding dynamic optimization

- Automated in-process measurement initiating responses

- ML-predicted preventative tool adjustments

- Robotics enabling untended continuous production

- AM-printed custom tooling matched to each unique job

Exciting times lie ahead as innovation unlocks stainless steel’s full potential across essential parts protecting modern life.