What Are Drill Bits Really Made Of – and How Do You Choose the Right One for Your Application?

Table of Contents

Drilling is one of the most common machining operations, yet it is also one of the most underestimated.

Why do drills break unexpectedly?

Why does tool life vary so much between seemingly similar jobs?

And why does changing a drill geometry or coating often deliver dramatic improvements in productivity?

The answer lies in understanding drill material, geometry, coating, cooling strategy, and application matching.

In this guide, we take a deep, engineering-focused look at modern drill tools — not from a catalog perspective, but from a real production and cost-per-hole viewpoint.

Why Is Drill Selection More Critical Than Many Manufacturers Think?

In milling and turning operations, tool selection is often carefully optimized.

However, drilling is still frequently treated as a “standard operation” — until problems occur.

In reality, drilling accounts for:

- A large percentage of total machining time

- High heat concentrationat the cutting zone

- Significant influence on hole quality, dimensional accuracy, and downstream operations

A poorly chosen drill does not only fail early — it increases:

- Scrap risk

- Cycle time

- Machine downtime

- Cost per hole

Choosing the right drill is therefore not optional — it is a strategic decision.

What Materials Are Drill Bits Made From?

Modern drills are typically manufactured from three main material families. Each one addresses a very different machining need.

High-Speed Steel (HSS): Is the Classic Still Relevant?

High-speed steel drills remain widely used due to their versatility and cost efficiency.

Key characteristics

- Good toughness

- Easy to regrind

- Low initial cost

Best suited for

- Mild steel

- Low-carbon steel

- Plastics

- Aluminum

HSS drills perform well at low to moderate cutting speeds and in applications where tool cost is more important than maximum productivity.

However, once cutting temperatures rise or materials become tougher, HSS quickly reaches its limits.

Cobalt High-Speed Steel (HSCO): When Heat Resistance Matters

HSCO drills (often M35 or M42) contain 5–8% cobalt, significantly improving hot hardness.

Why does cobalt matter?

- Higher red hardness

- Improved wear resistance

- Better edge stability at elevated temperatures

Typical applications

- Stainless steel

- Alloy steel

- Titanium alloys

- Cast steel

HSCO drills are often the minimum requirement for reliable stainless steel drilling in production environments.

Solid Carbide Drills: Why Are They the Industry Benchmark?

Solid carbide drills outperform all other drill materials when conditions are right.

Key advantages

- Extremely high hardness

- Excellent wear resistance

- Capable of very high cutting speeds

- Consistent hole quality over long tool life

Ideal for

- Stainless steel

- Cast iron

- High-temperature alloys

- Abrasive materials

- High-volume CNC production

The trade-off?

- Higher cost

- Lower toughness than steel

- Requires rigid machines and stable fixturing

When optimized correctly, carbide drills deliver the lowest cost per hole, despite higher initial investment.

Drill Material Comparison: Which One Should You Choose?

Drill Material | Hardness | Heat Resistance | Typical Speed | Tool Life | Cost |

HSS | Medium | Low | Low | Short | Low |

HSCO | Medium–High | Medium–High | Medium | Medium | Medium |

Solid Carbide | Very High | Very High | High | Long | High |

Are All Drill Sizes and Lengths the Same?

Far from it.

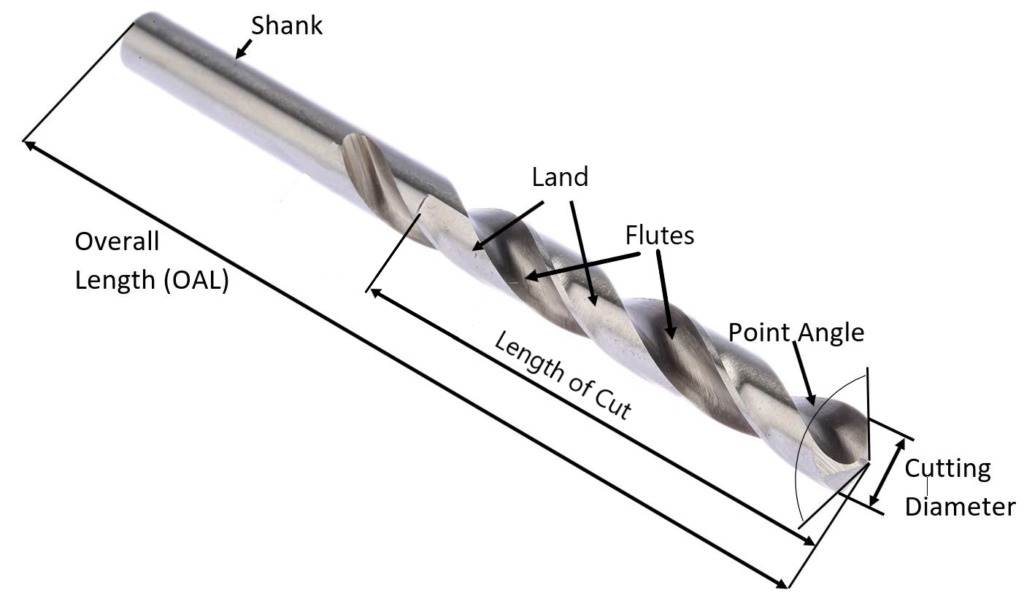

Why Does Drill Length Matter More Than Diameter?

Longer drills increase:

- Deflection

- Runout

- Vibration

- Risk of breakage

Rule of thumb:

Use the shortest drill possible for the application.

Common Drill Length Standards

Drill Type | Relative Length | Rigidity | Typical Use |

Screw Machine Length | Shortest | Very High | Precision, rigid setups |

Machine Length | Short | High | CNC production |

Jobber Length | Medium | Medium | General-purpose |

Taper Length | Medium–Long | Medium–Low | Special applications |

Extra Long | Long | Low | Deep holes |

Short drills dramatically improve tool life and hole accuracy — especially with carbide.

What Makes Drill Geometry So Important?

Drill geometry defines how material is cut, how chips flow, and how heat is managed.

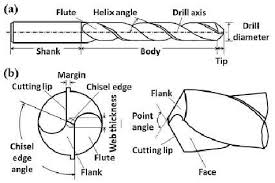

What Is a Drill Point Geometry?

The drill point includes:

- Point angle

- Cutting edges

- Chisel edge

- Margin

- Flute profile

Each element affects:

- Centering behavior

- Cutting forces

- Chip evacuation

- Tool wear pattern

Why Does the Point Angle Matter?

Smaller point angles (e.g. 118°)

- Better for softer materials

- Easier penetration

Larger point angles (e.g. 135°–140°)

- Better centering

- Lower thrust force

- Preferred for harder materials and CNC drilling

Self-centering split-point designs reduce walking and eliminate the need for spot drilling in many cases.

What Is the Role of Helix Angle (Rake Angle)?

The helix angle determines chip formation and evacuation.

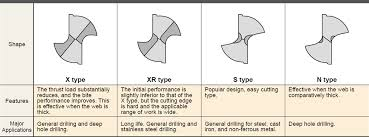

DIN 1836 Helix Angle Classification

Type | Helix Character | Typical Materials |

N-Type | Normal helix | Cast iron, non-ferrous metals |

H-Type | High helix | Steel, hard plastics |

W-Type | Tight helix | Aluminum, soft plastics |

- Higher helix→ long, curled chips

- Lower helix→ short, broken chips

Matching helix angle to chip behavior is essential for stable drilling.

Do Drill Coatings Really Make a Difference?

Absolutely — coatings are often the deciding factor in tool life and productivity.

Why Are Drill Coatings Used?

- Reduce friction

- Increase surface hardness

- Improve heat resistance

- Protect cutting edges

Most modern drills use PVD (Physical Vapor Deposition) coatings.

Common Drill Coatings and Their Applications

Coating | Key Property | Best For |

TiN | General wear resistance | Mild steel, general drilling |

TiAlN | High heat resistance | Alloy steel, stainless steel |

TiCN | Very high hardness | Copper alloys, nickel alloys |

AlTiN | Extreme heat stability | Hard and abrasive materials |

Note: Many coated drills are not suitable for regrinding, as coating removal reduces performance.

Internal Coolant or External Coolant: Does It Really Matter?

Yes — especially with carbide drills.

Why Is Internal Coolant So Important?

Internal coolant:

- Delivers coolant directly to the cutting zone

- Improves chip evacuation

- Stabilizes cutting temperature

- Extends tool life significantly

Recommended for

- Stainless steel

- High-temperature alloys

- Deep-hole drilling

- High-speed CNC operations

External Coolant: When Is It Acceptable?

External coolant can work for:

- Shallow holes (≤ 3×D)

- Softer materials

- Lower cutting speeds

However, compared to internal coolant:

- Cutting speed must be reduced (~20%)

- Chip evacuation is less reliable

What Are the Most Common Drilling Problems — and How Can You Solve Them?

Why Do Drills Break?

Common causes include:

- Incorrect cutting speed

- Excessive feed rate

- Chip packing in blind holes

- Poor coolant delivery

- Wrong geometry for the material

Solution:

Match speed, feed, geometry, and coolant strategy to the material — not the other way around.

Why Does Tool Wear Increase Too Fast?

- Insufficient cooling

- Incorrect coating choice

- Inadequate chip evacuation

- Excessive runout

Optimizing these factors often doubles or triples tool life without changing the drill material.

Why Are Chips Long and Uncontrollable?

- Feed rate too low

- Drill not sharp enough

- Helix angle unsuitable

Chip control is not cosmetic — it directly affects tool life and machine uptime.

Practical Drilling Tips That Improve Productivity Immediately

- Use the shortest drill length possible

- Prefer self-centering geometries

- Use guide drilling for holes deeper than 16×D

- Reduce feed on inclined entry surfaces

- Lower feed when crossing intersecting holes

- Clamp stacked materials tightly — no air gaps

Small process changes often deliver large productivity gains.

How Do You Choose the Best Drill for Your Application?

The best drill is not defined by material alone.

You must consider:

- Workpiece material

- Hole depth and diameter

- Machine rigidity

- Coolant capability

- Production volume

- Target cost per hole

A drill optimized for your exact conditions will always outperform a “universal” solution.

Final Thoughts: Drilling Is a System, Not Just a Tool

Successful drilling is the result of:

- Correct material selection

- Optimized geometry

- Suitable coating

- Effective cooling

- Stable machining conditions

When these elements work together, drilling becomes:

- Predictable

- Efficient

- Economical

If you are looking to reduce tool cost per hole, improve hole quality, or stabilize drilling in demanding materials, a properly engineered drill solution makes all the difference.

For application-specific recommendations, consulting experienced carbide tooling specialists ensures that every hole is drilled with confidence — not compromise.