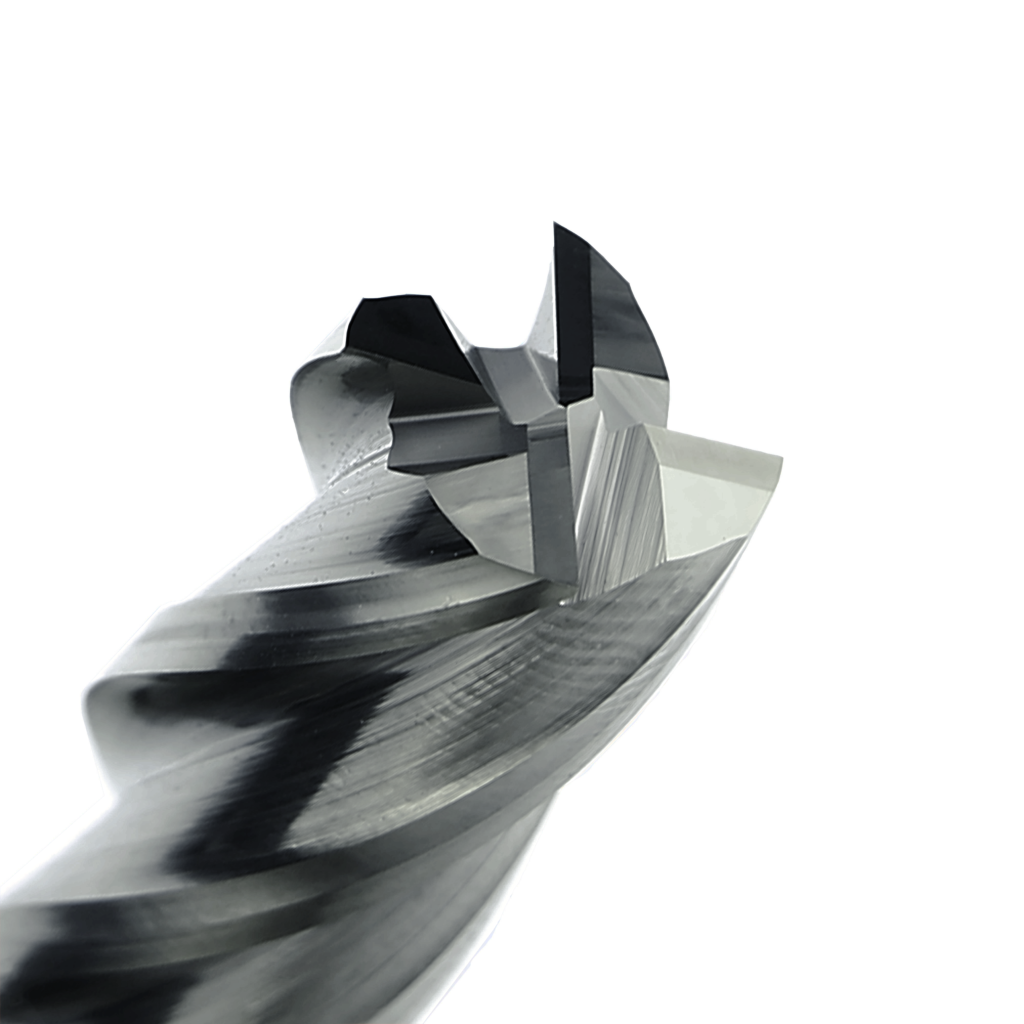

HNCarbide 4 flutes 55HRC steel carbide end mill cutter flat is designed for stable finishing and semi-finishing of alloy steel, carbon steel and pre-hardened steel up to 55HRC. Made from fine-grain solid carbide end mill cutter material and processed on advanced CNC grinding machines, it offers high dimensional accuracy, smooth surface finish and reliable tool life in continuous or intermittent cuts.

Optimized 4-flute geometry and reinforced core reduce vibration, improve edge stability and allow higher cutting speeds with consistent performance. This flat end mill carbide cutter is ideal for mould, parts and general engineering components that demand accuracy and repeatability. As a professional china cnc carbide end mill cutter manufacturer, HNCarbide provides multiple metric and inch sizes, coating options and special lengths to match different CNC machining requirements and setups.

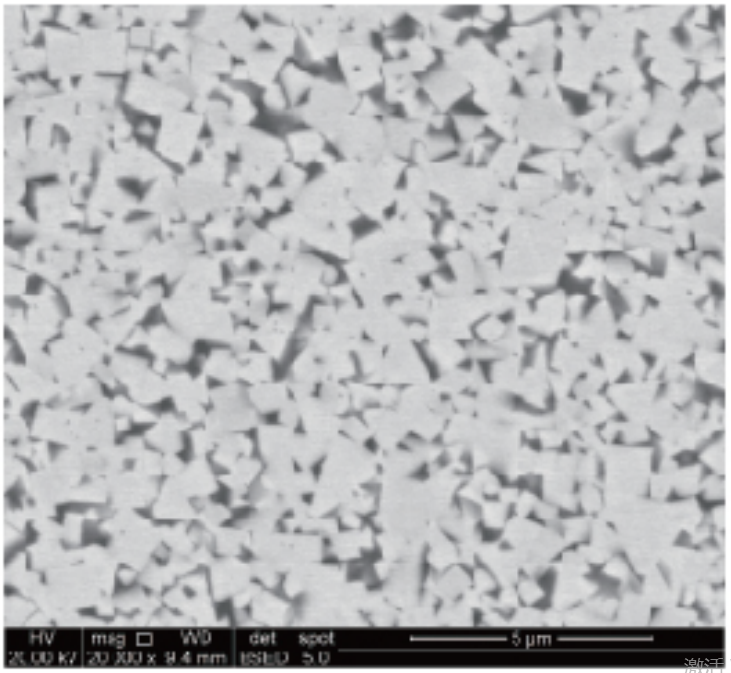

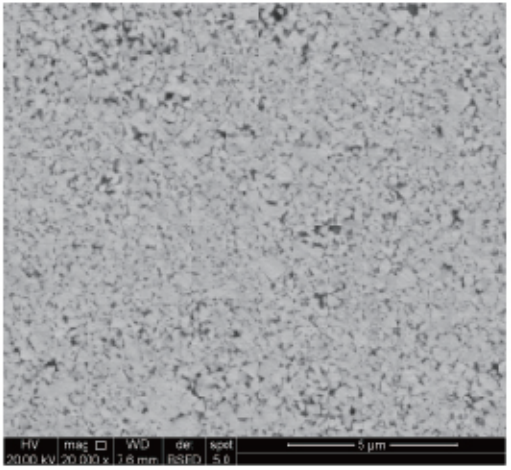

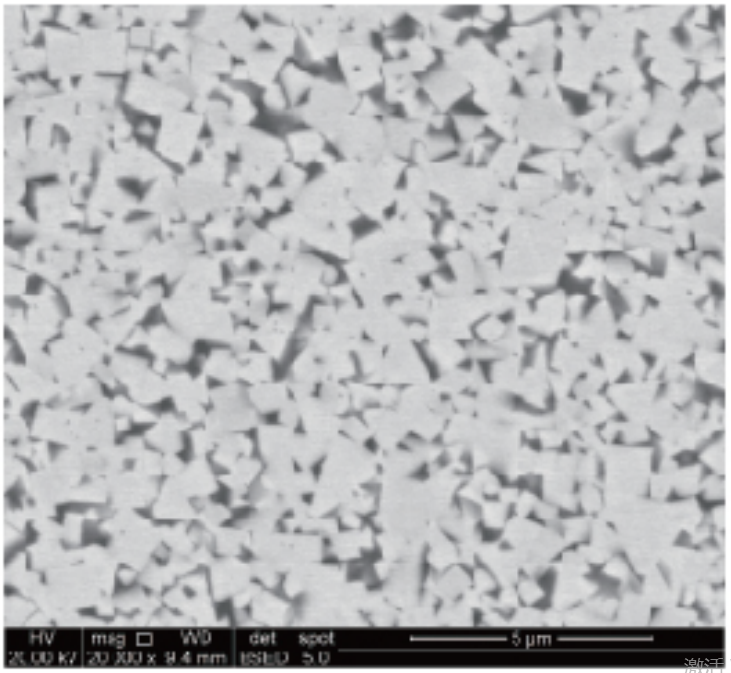

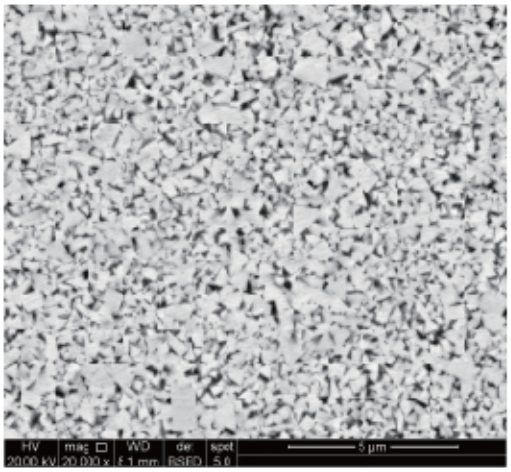

Grade HN40 is made from submicron WC powder, some speclal additlves added to optimize theproperties with good combination of hardness and toughness.

Its suitable for making drills and miling tools for machining stainless steel, tool steel and heat-resistingalloys.

| Grade | Cobalt content % | Grain size | Density g/cm³ | Hardness HRA | Hardness HV30 | MPa Transverse rupture strength | MPa ·m1/2 Fracture toughness MPa ·m1/2 |

|---|---|---|---|---|---|---|---|

| HN40 | 10 | 0.8 | 14.45 | 91.8 | 1,580 | 3,600 | 11.8 |

| Scientific name | Composition | Physical properties | Features | Typical applications |

|---|---|---|---|---|

| TiSiN | Ti (titanium): main element, forms TiN nanocrystalline phase. Si (silicon): usually 6–10%, forms amorphous Si₃N₄ phase, refines grains and increases hardness. N (nitrogen): combines with Ti and Si to form a composite structure. | Colour: TiSiN coatings usually appear bronze or dark grey-bronze; exact colour depends on Si content, deposition process (such as PVD) and thickness (1–4 μm). Hardness: 34–42 GPa (≈3400–4200 HV). Friction coefficient: 0.3–0.6 (against steel). Temperature resistance: 1000–1200°C (oxidation resistance). Coating thickness: 1–5 μm (typically 2–3 μm). Deposition temperature: 200–400°C (suitable for carbide tools). | Ultra-high hardness: amorphous Si₃N₄ phase suppresses dislocation movement, giving much higher hardness than TiN (~23 GPa) and TiAlN (~35 GPa). High-temperature stability: suitable for dry cutting and high-speed machining (e.g. quenched steels HRC 60+). Anti-adhesion: reduces built-up edge when machining aluminium alloys, stainless steels and other sticky materials. | Tool coatings: drills, mills (especially suitable for PCB routers, tool life increased by 2–3 times). High-speed cutting of quenched steels, titanium alloys and high-nickel alloys. Mould strengthening: die-casting moulds and stamping dies, improving wear resistance. Industrial parts: piston rings and other high-temperature wear parts. |

HNCarbide provides carbide end mill cutter tools for a wide range of materials: carbon steel, alloy steel, stainless steel, cast iron, tool steel, hardened steel, aluminum and non-ferrous alloys. Different series are optimized for specific hardness ranges (e.g. 55HRC, 60HRC, 65HRC) and applications such as roughing, semi-finishing and finishing. By choosing the right grade, geometry and coating, one end mill carbide cutter can deliver stable performance on multiple materials in your CNC shop.

Flute number is directly related to chip evacuation and rigidity. 2-flute carbide end mill cutter designs are ideal for aluminum and non-ferrous materials where larger chip pockets are needed. 3-flute and 4-flute end mill carbide cutter tools offer higher rigidity and more cutting edges per revolution, which is better for steel, stainless steel and hardened steel. For slotting or roughing you may use fewer flutes; for finishing and side milling, higher flute counts often provide better surface finish.

For distributors and regular customers, we can offer a structured carbide end mill cutter price list based on series, coating and order quantity. For new users, carbide end mill cutter price is usually quoted according to size range, material grade and customization level. Most standard items have low MOQ and we can provide sample pieces for testing before bulk order, helping you verify performance in your own CNC machining conditions.

Yes. We can produce non-standard tools according to your drawings, samples or machining requirements (material, coating, size, tolerance and application). Our engineers will evaluate and provide a quotation and lead time.

For serious buyers and distributors, we can offer free standard samples if in stock. Usually you only need to cover the freight cost. For customized tools, a sample fee may apply, which can be refunded or deducted in bulk orders.

Yes.

Regional or customer protection based on sales targets, avoiding price wars among our partners.

Catalogs, brochures, product photos, technical data sheets, online materials.

For key partners, joint promotion, exhibitions and digital marketing support.

Safety stock for fast-moving items and forecast-based production.

Priority production and regular shipments to reduce stock-out risk.

Clear quality warranty policy, quick response to claims.

Replacement, credit or other solutions after confirmation of issues.

Tool selection and cutting parameter advice.

Problem analysis for different materials and machines.

Online training, documents, and when possible, on-site support for key accounts.

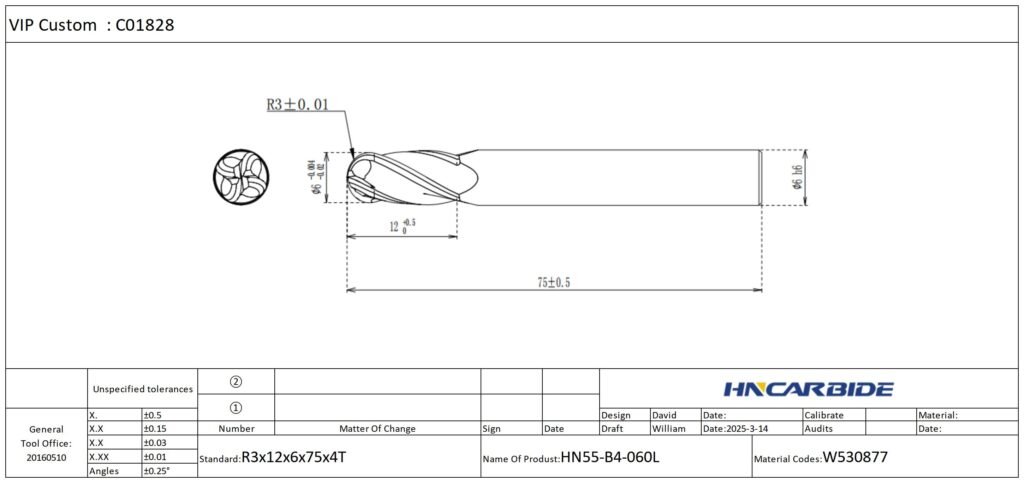

HM Series 4 flutes carbide end mill cutter flat from HNCarbide is designed for high-efficiency finishing and semi-finishing of alloy steel, carbon steel and pre-hardened steel. Produced from premium micro-grain substrate and finished on advanced CNC grinding lines, this solid carbide end mill cutter delivers accurate dimensions, clean surface quality and reliable tool life in stable and light interrupted cutting.

The HM Series features an optimized 4-flute end mill carbide cutter geometry with a strong core and carefully controlled rake and relief angles to reduce vibration, enhance edge strength and support higher cutting speeds. Depending on coating choice, it is suitable for general engineering, die and mould, and precision parts machining. As a professional china cnc carbide end mill cutter manufacturer, HNCarbide offers the HM Series in a wide range of metric and inch sizes, with options for customized flute length, shank style and coating to match your CNC setup.

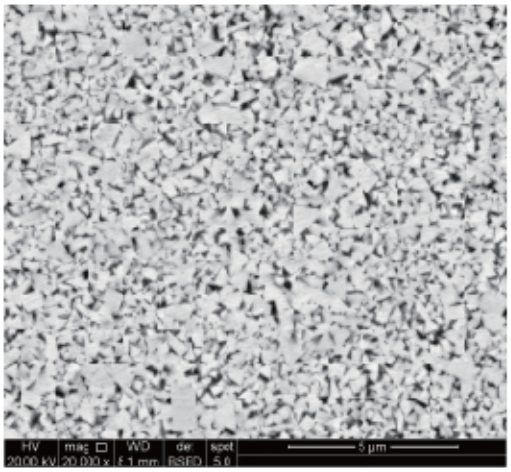

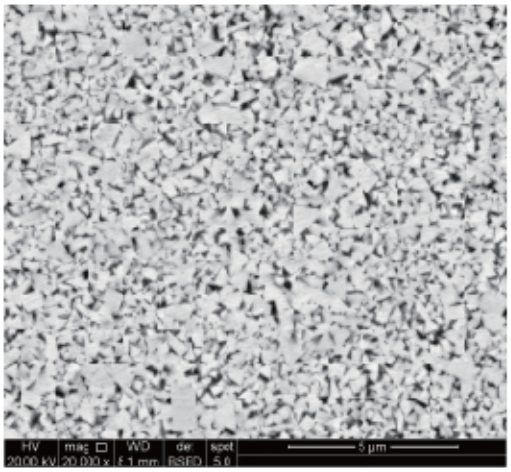

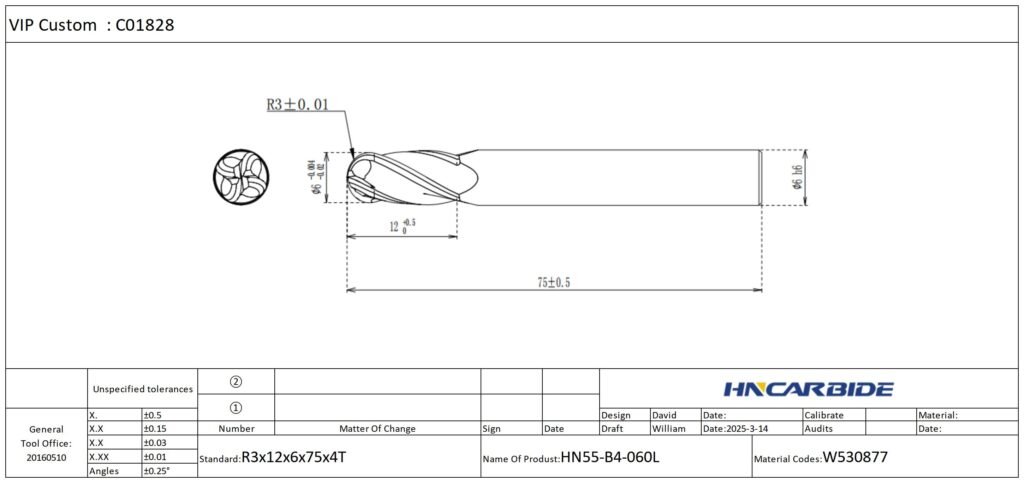

Grade HN55 is made from ultrafine close to nanometer sized WC powder, with very high wear resistancet’s suitable for making miling、 drilling tools and reamers, for high-speed miling of materials with highhardness.

| Grade | Cobalt content % | Grain size | Density g/cm³ | Hardness HRA | Hardness HV30 | MPa Transverse rupture strength | MPa ·m1/2 Fracture toughness MPa ·m1/2 |

|---|---|---|---|---|---|---|---|

| HN55 | 9 | 0.3 | 14.50 | 93.8 | 1,960 | 3,800 | 8.0 |

| Scientific name | Composition | Physical properties | Features | Typical applications |

|---|---|---|---|---|

| AlCrSiN | Aluminium–chromium–silicon nitride coating containing Si | Hardness: not clearly specified, but the presence of Si significantly increases hardness and toughness (estimated HV>3500). | Si forms a denser nanostructure, improving wear resistance and high-temperature stability. | Specially designed for drills, end mills and ball-nose mills and other shank-type tools. Suitable for machining high-hardness materials (such as quenched workpieces) and materials after heat treatment. |

HNCarbide provides carbide end mill cutter tools for a wide range of materials: carbon steel, alloy steel, stainless steel, cast iron, tool steel, hardened steel, aluminum and non-ferrous alloys. Different series are optimized for specific hardness ranges (e.g. 55HRC, 60HRC, 65HRC) and applications such as roughing, semi-finishing and finishing. By choosing the right grade, geometry and coating, one end mill carbide cutter can deliver stable performance on multiple materials in your CNC shop.

Flute number is directly related to chip evacuation and rigidity. 2-flute carbide end mill cutter designs are ideal for aluminum and non-ferrous materials where larger chip pockets are needed. 3-flute and 4-flute end mill carbide cutter tools offer higher rigidity and more cutting edges per revolution, which is better for steel, stainless steel and hardened steel. For slotting or roughing you may use fewer flutes; for finishing and side milling, higher flute counts often provide better surface finish.

For distributors and regular customers, we can offer a structured carbide end mill cutter price list based on series, coating and order quantity. For new users, carbide end mill cutter price is usually quoted according to size range, material grade and customization level. Most standard items have low MOQ and we can provide sample pieces for testing before bulk order, helping you verify performance in your own CNC machining conditions.

Yes. We can produce non-standard tools according to your drawings, samples or machining requirements (material, coating, size, tolerance and application). Our engineers will evaluate and provide a quotation and lead time.

For serious buyers and distributors, we can offer free standard samples if in stock. Usually you only need to cover the freight cost. For customized tools, a sample fee may apply, which can be refunded or deducted in bulk orders.

Yes.

Regional or customer protection based on sales targets, avoiding price wars among our partners.

Catalogs, brochures, product photos, technical data sheets, online materials.

For key partners, joint promotion, exhibitions and digital marketing support.

Safety stock for fast-moving items and forecast-based production.

Priority production and regular shipments to reduce stock-out risk.

Clear quality warranty policy, quick response to claims.

Replacement, credit or other solutions after confirmation of issues.

Tool selection and cutting parameter advice.

Problem analysis for different materials and machines.

Online training, documents, and when possible, on-site support for key accounts.

HNCarbide 4 flutes 60HRC stainless steel carbide end mill cutter flat is designed for high-efficiency machining of stainless steel, alloy steel and pre-hardened steel up to 60HRC. Made from ultra-fine grain solid carbide end mill cutter substrate and finished on advanced CNC grinding machines, it offers excellent wear resistance, stable cutting and reliable tool life at medium to high cutting speeds.

The optimized 4-flute end mill carbide cutter geometry, reinforced core and smooth chip evacuation reduce vibration, improve edge strength and deliver a bright surface finish in continuous or light interrupted cuts. As a professional china cnc carbide end mill cutter supplier, HNCarbide provides this tungsten carbide end mill cutter in a wide range of metric and inch sizes, with options for coating, flute length and shank style to meet different mould, precision parts and general engineering CNC applications.

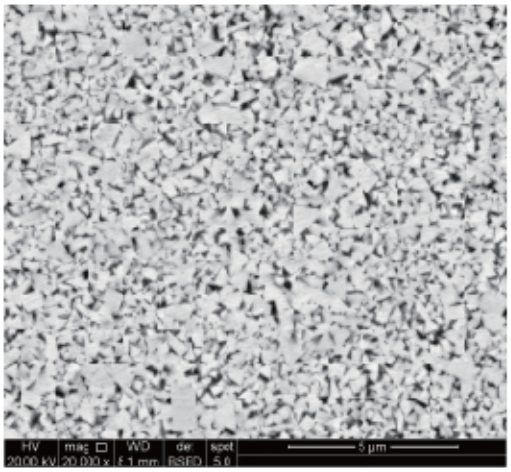

Grade HN44F is made from submicron WC powder, some special additives added.

It’s suitable for making drills and end mills, especially for machining steel,Al-based alloys and Ti-basedalloys.

| Grade | Cobalt content % | Grain size | Density g/cm³ | Hardness HRA | Hardness HV30 | MPa Transverse rupture strength | MPa ·m1/2 Fracture toughness MPa ·m1/2 |

|---|---|---|---|---|---|---|---|

| HN44F | 12 | 0.4 | 14.15 | 92.6 | 1,720 | 4,200 | 9.6 |

| Scientific name | Composition | Physical properties | Features | Typical applications |

|---|---|---|---|---|

| CrAlTiSiN | Cr: 12–16% Al: 20–24% Ti: 4–8% Si: 6–10% N: 48–52% | Ultra-high hardness: hardness can reach 38–40 GPa (e.g. CrAlSiN/TiAlSiN modulated coatings), much higher than traditional TiN or CrN. Si forms amorphous Si₃N₄, which suppresses dislocation movement and improves wear resistance. Excellent high-temperature performance: oxidation temperature up to 1000–1100°C, suitable for high-speed dry cutting. At high temperature, a dense Al₂O₃ and Cr₂O₃ oxide layer forms on the surface, slowing further oxidation. Low friction coefficient: about 0.375–0.675, depending on modulation period and Si content. Strong adhesion: with transition-layer design (such as AlCrTi alloy layer), critical load can exceed 18 N (scratch test). | High-speed cutting tools: such as mills and drills, suitable for hardened steels, titanium alloys and other difficult-to-machine materials. Mould surface reinforcement: improves wear resistance and thermal-fatigue resistance of stamping dies. Aerospace components: such as turbine-blade coatings, resisting high-temperature oxidation and particle erosion. |

HNCarbide provides carbide end mill cutter tools for a wide range of materials: carbon steel, alloy steel, stainless steel, cast iron, tool steel, hardened steel, aluminum and non-ferrous alloys. Different series are optimized for specific hardness ranges (e.g. 55HRC, 60HRC, 65HRC) and applications such as roughing, semi-finishing and finishing. By choosing the right grade, geometry and coating, one end mill carbide cutter can deliver stable performance on multiple materials in your CNC shop.

Flute number is directly related to chip evacuation and rigidity. 2-flute carbide end mill cutter designs are ideal for aluminum and non-ferrous materials where larger chip pockets are needed. 3-flute and 4-flute end mill carbide cutter tools offer higher rigidity and more cutting edges per revolution, which is better for steel, stainless steel and hardened steel. For slotting or roughing you may use fewer flutes; for finishing and side milling, higher flute counts often provide better surface finish.

For distributors and regular customers, we can offer a structured carbide end mill cutter price list based on series, coating and order quantity. For new users, carbide end mill cutter price is usually quoted according to size range, material grade and customization level. Most standard items have low MOQ and we can provide sample pieces for testing before bulk order, helping you verify performance in your own CNC machining conditions.

Yes. We can produce non-standard tools according to your drawings, samples or machining requirements (material, coating, size, tolerance and application). Our engineers will evaluate and provide a quotation and lead time.

For serious buyers and distributors, we can offer free standard samples if in stock. Usually you only need to cover the freight cost. For customized tools, a sample fee may apply, which can be refunded or deducted in bulk orders.

Yes.

Regional or customer protection based on sales targets, avoiding price wars among our partners.

Catalogs, brochures, product photos, technical data sheets, online materials.

For key partners, joint promotion, exhibitions and digital marketing support.

Safety stock for fast-moving items and forecast-based production.

Priority production and regular shipments to reduce stock-out risk.

Clear quality warranty policy, quick response to claims.

Replacement, credit or other solutions after confirmation of issues.

Tool selection and cutting parameter advice.

Problem analysis for different materials and machines.

Online training, documents, and when possible, on-site support for key accounts.

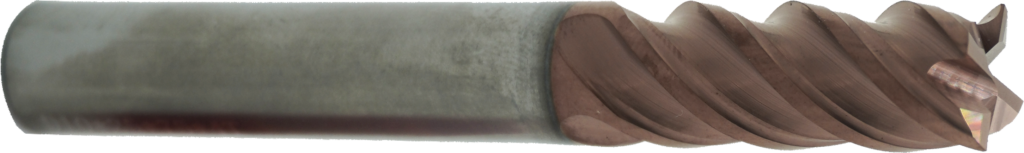

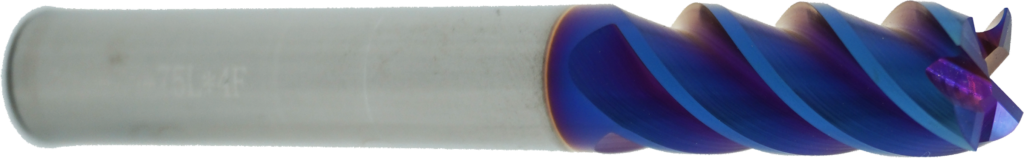

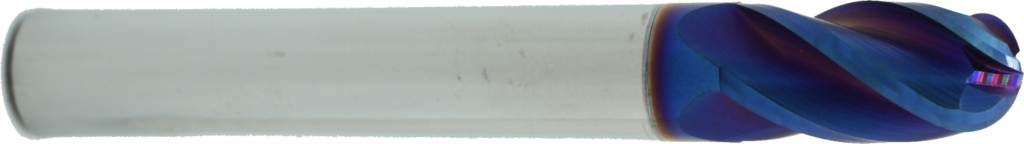

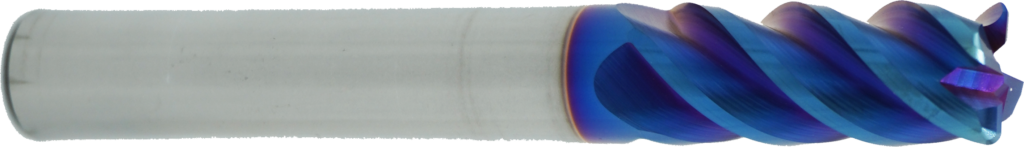

HNCarbide 4 flutes 65HRC blue nano coated carbide end mill cutter flat is engineered for high-speed machining of hardened steel, stainless steel and alloy steel up to 65HRC. Using ultra-fine grain solid carbide end mill cutter substrate and advanced CNC grinding, this tool offers outstanding wear resistance, stable cutting and long tool life under heavy load and high-temperature conditions.

The optimized 4-flute end mill carbide cutter geometry, reinforced core and smooth chip evacuation help reduce vibration, maintain edge strength and deliver an excellent surface finish in continuous or light interrupted cuts. The blue nano coating further improves heat resistance and anti-adhesion performance, making it ideal for mould, die and precision parts machining. As a professional china cnc carbide end mill cutter supplier, HNCarbide provides this tungsten carbide end mill cutter in multiple metric and inch sizes, with customizable flute length, shank style and coating to match different CNC machining requirements.

Grade HN44F is made from submicron WC powder, some special additives added.

It’s suitable for making drills and end mills, especially for machining steel,Al-based alloys and Ti-basedalloys.

| Grade | Cobalt content % | Grain size | Density g/cm³ | Hardness HRA | Hardness HV30 | MPa Transverse rupture strength | MPa ·m1/2 Fracture toughness MPa ·m1/2 |

|---|---|---|---|---|---|---|---|

| HN44F | 12 | 0.4 | 14.15 | 92.6 | 1,720 | 4,200 | 9.6 |

| Scientific name | Composition | Physical properties | Features | Typical applications |

|---|---|---|---|---|

| Nano-Blue | Blue surface layer: may contain AlCrN (aluminium-chromium nitride) or TiSiN (titanium–silicon nitride); the blue colour comes from nano-structured interference. Nanomultilayer structure: alternating layers such as TiN/AlN (individual layer thickness <50 nm) to increase hardness and thermal stability. | Hardness: 3000–4000 HV (nano-indentation). Friction coefficient: 0.1–0.3 (lower when combined with DLC). Heat resistance: stable up to 1000°C (oxidation starts above 800°C). Adhesion strength: ≥70 N (critical load in scratch test). Surface roughness: Ra <0.05 μm (after polishing). | Blue appearance: achieved by nano-optical thin-film design, and can serve as wear indicator (colour change shows coating loss). Self-lubricating: some Si- or WC-containing nanocoatings can form a silica-based lubricating layer at high temperature. | Recommended workpiece materials High-hardness steels (HRC>50, such as mould steel, bearing steel). High-temperature alloys (nickel-based / titanium alloys, relying on coating heat resistance). Non-ferrous metals (aluminium and copper alloys, requiring low-friction coating to prevent built-up edge). Composites (CFRP, avoiding adverse reactions between coating and fibres). Typical application fields Aerospace: machining turbine-blade dovetails, milling titanium-alloy structural parts. Automotive moulds: high-precision cavity milling, balancing efficiency and surface quality. Medical devices: micro-machining of cobalt-chromium artificial joints. |

HNCarbide provides carbide end mill cutter tools for a wide range of materials: carbon steel, alloy steel, stainless steel, cast iron, tool steel, hardened steel, aluminum and non-ferrous alloys. Different series are optimized for specific hardness ranges (e.g. 55HRC, 60HRC, 65HRC) and applications such as roughing, semi-finishing and finishing. By choosing the right grade, geometry and coating, one end mill carbide cutter can deliver stable performance on multiple materials in your CNC shop.

Flute number is directly related to chip evacuation and rigidity. 2-flute carbide end mill cutter designs are ideal for aluminum and non-ferrous materials where larger chip pockets are needed. 3-flute and 4-flute end mill carbide cutter tools offer higher rigidity and more cutting edges per revolution, which is better for steel, stainless steel and hardened steel. For slotting or roughing you may use fewer flutes; for finishing and side milling, higher flute counts often provide better surface finish.

For distributors and regular customers, we can offer a structured carbide end mill cutter price list based on series, coating and order quantity. For new users, carbide end mill cutter price is usually quoted according to size range, material grade and customization level. Most standard items have low MOQ and we can provide sample pieces for testing before bulk order, helping you verify performance in your own CNC machining conditions.

Yes. We can produce non-standard tools according to your drawings, samples or machining requirements (material, coating, size, tolerance and application). Our engineers will evaluate and provide a quotation and lead time.

For serious buyers and distributors, we can offer free standard samples if in stock. Usually you only need to cover the freight cost. For customized tools, a sample fee may apply, which can be refunded or deducted in bulk orders.

Yes.

Regional or customer protection based on sales targets, avoiding price wars among our partners.

Catalogs, brochures, product photos, technical data sheets, online materials.

For key partners, joint promotion, exhibitions and digital marketing support.

Safety stock for fast-moving items and forecast-based production.

Priority production and regular shipments to reduce stock-out risk.

Clear quality warranty policy, quick response to claims.

Replacement, credit or other solutions after confirmation of issues.

Tool selection and cutting parameter advice.

Problem analysis for different materials and machines.

Online training, documents, and when possible, on-site support for key accounts.

HNCarbide GM Series 2-flute ball carbide end mill cutter is designed for high-speed, high-precision contouring and 3D surface machining in mould, die and precision parts manufacturing. Made from premium micro-grain solid carbide end mill cutter substrate and finished on advanced CNC grinding lines, it offers excellent edge sharpness, stable cutting and reliable tool life in steels, stainless steels and hardened materials within the recommended hardness range.

The 2-flute ball end mill carbide cutter geometry provides smooth chip evacuation, reduced cutting resistance and a superior surface finish in slotting, profiling and plunging operations. Optimized helix and rake angles help control heat generation and minimize vibration, supporting consistent accuracy on complex 3D surfaces. As a professional china cnc carbide end mill cutter manufacturer, HNCarbide supplies GM Series ball tungsten carbide end mill cutter tools in a wide selection of metric and inch sizes, with optional coatings and customized lengths to match different CNC machining strategies and materials.

Grade HN40 is made from submicron WC powder, some speclal additlves added to optimize theproperties with good combination of hardness and toughness.

Its suitable for making drills and miling tools for machining stainless steel, tool steel and heat-resistingalloys.

| Grade | Cobalt content % | Grain size | Density g/cm³ | Hardness HRA | Hardness HV30 | MPa Transverse rupture strength | MPa ·m1/2 Fracture toughness MPa ·m1/2 |

|---|---|---|---|---|---|---|---|

| HN40 | 10 | 0.8 | 14.45 | 91.8 | 1,580 | 3,600 | 11.8 |

| Scientific name | Composition | Physical properties | Features | Typical applications |

|---|---|---|---|---|

| ALCRN | Al: 18–32% Cr: 10–25% N: 45–57% | Hardness: 2800–3200 HV (≈30–32 GPa) Thickness: 1–5 μm (typically 3–4 μm in applications) Oxidation temperature: 1000–1100°C (short-term up to 1100°C) Deposition temperature: <500°C (suitable for HSS and carbide substrates) | Red hardness: maintains hardness even at 1100°C, better than TiAlN (whose hardness drops above about 900°C). Adhesion: critical load up to 40 N (with optimized process). Wear resistance: suitable for high-speed cutting and dry machining, especially effective on stainless steels and alloy steels. | Cutting tools: end mills, gear cutters, drills (e.g. Balinit Alcorna series). Moulds: aluminium die-casting moulds, stamping tools. Industrial parts: piston rings, high-temperature wear-resistant parts (combined with suitable interlayer design). |

HNCarbide provides carbide end mill cutter tools for a wide range of materials: carbon steel, alloy steel, stainless steel, cast iron, tool steel, hardened steel, aluminum and non-ferrous alloys. Different series are optimized for specific hardness ranges (e.g. 55HRC, 60HRC, 65HRC) and applications such as roughing, semi-finishing and finishing. By choosing the right grade, geometry and coating, one end mill carbide cutter can deliver stable performance on multiple materials in your CNC shop.

Flute number is directly related to chip evacuation and rigidity. 2-flute carbide end mill cutter designs are ideal for aluminum and non-ferrous materials where larger chip pockets are needed. 3-flute and 4-flute end mill carbide cutter tools offer higher rigidity and more cutting edges per revolution, which is better for steel, stainless steel and hardened steel. For slotting or roughing you may use fewer flutes; for finishing and side milling, higher flute counts often provide better surface finish.

For distributors and regular customers, we can offer a structured carbide end mill cutter price list based on series, coating and order quantity. For new users, carbide end mill cutter price is usually quoted according to size range, material grade and customization level. Most standard items have low MOQ and we can provide sample pieces for testing before bulk order, helping you verify performance in your own CNC machining conditions.

Yes. We can produce non-standard tools according to your drawings, samples or machining requirements (material, coating, size, tolerance and application). Our engineers will evaluate and provide a quotation and lead time.

For serious buyers and distributors, we can offer free standard samples if in stock. Usually you only need to cover the freight cost. For customized tools, a sample fee may apply, which can be refunded or deducted in bulk orders.

Yes.

Regional or customer protection based on sales targets, avoiding price wars among our partners.

Catalogs, brochures, product photos, technical data sheets, online materials.

For key partners, joint promotion, exhibitions and digital marketing support.

Safety stock for fast-moving items and forecast-based production.

Priority production and regular shipments to reduce stock-out risk.

Clear quality warranty policy, quick response to claims.

Replacement, credit or other solutions after confirmation of issues.

Tool selection and cutting parameter advice.

Problem analysis for different materials and machines.

Online training, documents, and when possible, on-site support for key accounts.

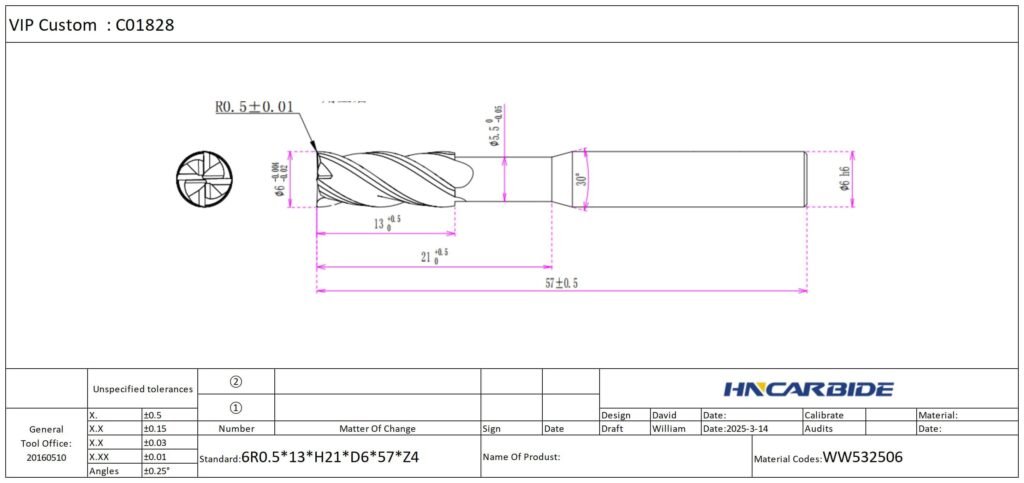

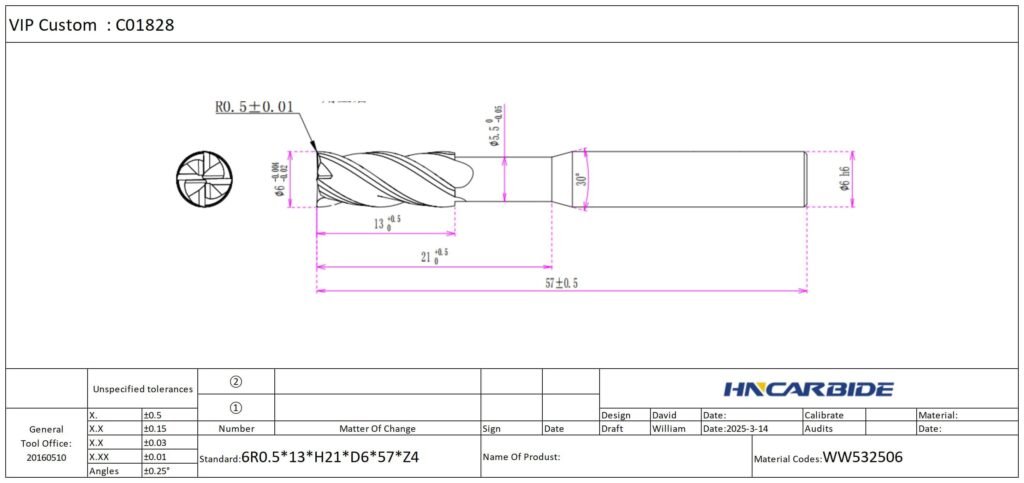

Our ball end mill drawings clearly show key ball end mill dimensions such as diameter, radius, flute length and overall length. This helps you confirm the right ball end mill sizes for your CNC setup and machining depth before ordering.

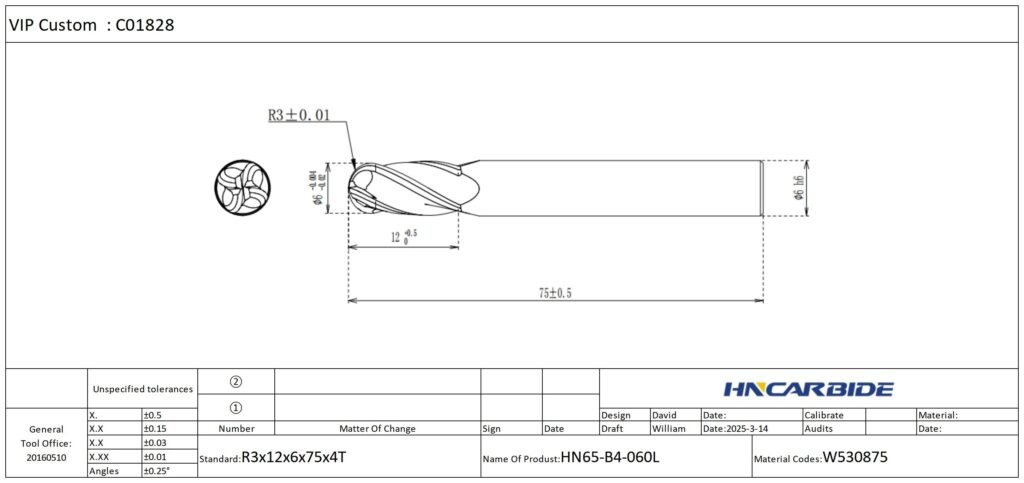

HNCarbide 65HRC blue nano coated 4 flute ball carbide end mill cutter is designed for high-speed finishing and 3D profiling of hardened steel, alloy steel and stainless steel up to 65HRC. Made from ultra-fine grain solid carbide end mill cutter substrate and ground on advanced CNC machines, it offers excellent wear resistance, edge stability and long tool life under high-temperature cutting conditions.

The 4-flute ball nose end mill carbide cutter geometry combines a reinforced core with smooth chip evacuation to reduce vibration and deliver a fine surface finish on moulds, dies and precision components. The blue nano coating enhances heat resistance and anti-adhesion performance, helping to maintain consistent accuracy on complex contours. As a professional china cnc carbide end mill cutter supplier, HNCarbide provides this tungsten carbide end mill cutter in a wide range of metric and inch sizes, with optional customized flute length, shank style and coating to fit different CNC machining setups.

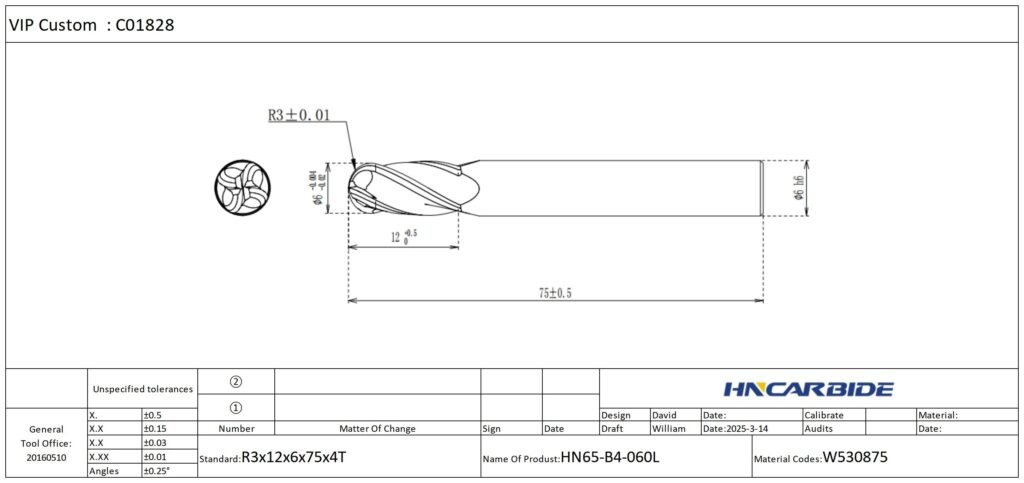

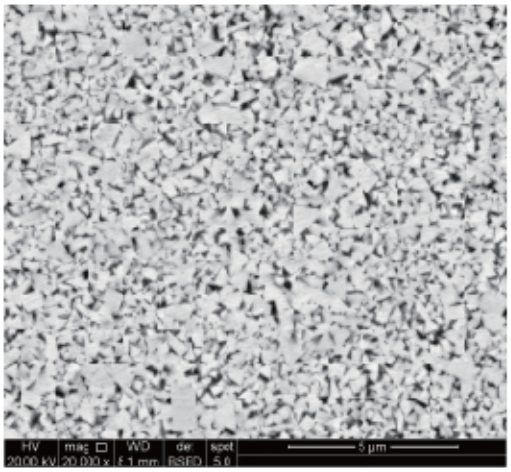

Grade HN44F is made from submicron WC powder, some special additives added.

It’s suitable for making drills and end mills, especially for machining steel,Al-based alloys and Ti-basedalloys.

| Grade | Cobalt content % | Grain size | Density g/cm³ | Hardness HRA | Hardness HV30 | MPa Transverse rupture strength | MPa ·m1/2 Fracture toughness MPa ·m1/2 |

|---|---|---|---|---|---|---|---|

| HN44F | 12 | 0.4 | 14.15 | 92.6 | 1,720 | 4,200 | 9.6 |

| Scientific name | Composition | Physical properties | Features | Typical applications |

|---|---|---|---|---|

| Nano-Blue | Blue surface layer: may contain AlCrN (aluminium-chromium nitride) or TiSiN (titanium–silicon nitride); the blue colour comes from nano-structured interference. Nanomultilayer structure: alternating layers such as TiN/AlN (individual layer thickness <50 nm) to increase hardness and thermal stability. | Hardness: 3000–4000 HV (nano-indentation). Friction coefficient: 0.1–0.3 (lower when combined with DLC). Heat resistance: stable up to 1000°C (oxidation starts above 800°C). Adhesion strength: ≥70 N (critical load in scratch test). Surface roughness: Ra <0.05 μm (after polishing). | Blue appearance: achieved by nano-optical thin-film design, and can serve as wear indicator (colour change shows coating loss). Self-lubricating: some Si- or WC-containing nanocoatings can form a silica-based lubricating layer at high temperature. | Recommended workpiece materials High-hardness steels (HRC>50, such as mould steel, bearing steel). High-temperature alloys (nickel-based / titanium alloys, relying on coating heat resistance). Non-ferrous metals (aluminium and copper alloys, requiring low-friction coating to prevent built-up edge). Composites (CFRP, avoiding adverse reactions between coating and fibres). Typical application fields Aerospace: machining turbine-blade dovetails, milling titanium-alloy structural parts. Automotive moulds: high-precision cavity milling, balancing efficiency and surface quality. Medical devices: micro-machining of cobalt-chromium artificial joints. |

Our ball end mill drawings clearly show key ball end mill dimensions such as diameter, radius, flute length and overall length. This helps you confirm the right ball end mill sizes for your CNC setup and machining depth before ordering.

HNCarbide provides carbide end mill cutter tools for a wide range of materials: carbon steel, alloy steel, stainless steel, cast iron, tool steel, hardened steel, aluminum and non-ferrous alloys. Different series are optimized for specific hardness ranges (e.g. 55HRC, 60HRC, 65HRC) and applications such as roughing, semi-finishing and finishing. By choosing the right grade, geometry and coating, one end mill carbide cutter can deliver stable performance on multiple materials in your CNC shop.

Flute number is directly related to chip evacuation and rigidity. 2-flute carbide end mill cutter designs are ideal for aluminum and non-ferrous materials where larger chip pockets are needed. 3-flute and 4-flute end mill carbide cutter tools offer higher rigidity and more cutting edges per revolution, which is better for steel, stainless steel and hardened steel. For slotting or roughing you may use fewer flutes; for finishing and side milling, higher flute counts often provide better surface finish.

For distributors and regular customers, we can offer a structured carbide end mill cutter price list based on series, coating and order quantity. For new users, carbide end mill cutter price is usually quoted according to size range, material grade and customization level. Most standard items have low MOQ and we can provide sample pieces for testing before bulk order, helping you verify performance in your own CNC machining conditions.

Yes. We can produce non-standard tools according to your drawings, samples or machining requirements (material, coating, size, tolerance and application). Our engineers will evaluate and provide a quotation and lead time.

For serious buyers and distributors, we can offer free standard samples if in stock. Usually you only need to cover the freight cost. For customized tools, a sample fee may apply, which can be refunded or deducted in bulk orders.

Yes.

Regional or customer protection based on sales targets, avoiding price wars among our partners.

Catalogs, brochures, product photos, technical data sheets, online materials.

For key partners, joint promotion, exhibitions and digital marketing support.

Safety stock for fast-moving items and forecast-based production.

Priority production and regular shipments to reduce stock-out risk.

Clear quality warranty policy, quick response to claims.

Replacement, credit or other solutions after confirmation of issues.

Tool selection and cutting parameter advice.

Problem analysis for different materials and machines.

Online training, documents, and when possible, on-site support for key accounts.

HNCarbide HRC60 4 flute corner radius carbide end mill cutter for stainless steel is designed for stable, high-efficiency machining of austenitic and martensitic stainless steels, as well as alloy steels up to 60HRC. Using ultra-fine grain solid carbide end mill cutter substrate and advanced CNC grinding, it delivers excellent wear resistance, edge strength and dimensional accuracy in continuous and light interrupted cutting.

The 4-flute end mill carbide cutter geometry with corner radius reduces chipping on the cutting edge, improves tool life and helps achieve a smoother surface finish on shoulders and pockets. Optimized helix angle and flute design support reliable chip evacuation while minimizing vibration and work hardening in difficult stainless materials. As a professional china cnc carbide end mill cutter manufacturer, HNCarbide offers this HRC60 corner radius tungsten carbide end mill cutter in a wide range of metric and inch sizes, with optional coatings and customized lengths for different CNC machining setups.

Grade HN44F is made from submicron WC powder, some special additives added.

It’s suitable for making drills and end mills, especially for machining steel,Al-based alloys and Ti-basedalloys.

| Grade | Cobalt content % | Grain size | Density g/cm³ | Hardness HRA | Hardness HV30 | MPa Transverse rupture strength | MPa ·m1/2 Fracture toughness MPa ·m1/2 |

|---|---|---|---|---|---|---|---|

| HN44F | 12 | 0.4 | 14.15 | 92.6 | 1,720 | 4,200 | 9.6 |

| Scientific name | Composition | Physical properties | Features | Typical applications |

|---|---|---|---|---|

| TiSiN | Ti (titanium): main element, forms TiN nanocrystalline phase. Si (silicon): usually 6–10%, forms amorphous Si₃N₄ phase, refines grains and increases hardness. N (nitrogen): combines with Ti and Si to form a composite structure. | Colour: TiSiN coatings usually appear bronze or dark grey-bronze; exact colour depends on Si content, deposition process (such as PVD) and thickness (1–4 μm). Hardness: 34–42 GPa (≈3400–4200 HV). Friction coefficient: 0.3–0.6 (against steel). Temperature resistance: 1000–1200°C (oxidation resistance). Coating thickness: 1–5 μm (typically 2–3 μm). Deposition temperature: 200–400°C (suitable for carbide tools). | Ultra-high hardness: amorphous Si₃N₄ phase suppresses dislocation movement, giving much higher hardness than TiN (~23 GPa) and TiAlN (~35 GPa). High-temperature stability: suitable for dry cutting and high-speed machining (e.g. quenched steels HRC 60+). Anti-adhesion: reduces built-up edge when machining aluminium alloys, stainless steels and other sticky materials. | Tool coatings: drills, mills (especially suitable for PCB routers, tool life increased by 2–3 times). High-speed cutting of quenched steels, titanium alloys and high-nickel alloys. Mould strengthening: die-casting moulds and stamping dies, improving wear resistance. Industrial parts: piston rings and other high-temperature wear parts. |

Our Corner Radius End Mill drawings clearly show key Corner Radius End Mill dimensions such as diameter, radius, flute length and overall length. This helps you confirm the right Corner Radius End Mill sizes for your CNC setup and machining depth before ordering.

HNCarbide provides carbide end mill cutter tools for a wide range of materials: carbon steel, alloy steel, stainless steel, cast iron, tool steel, hardened steel, aluminum and non-ferrous alloys. Different series are optimized for specific hardness ranges (e.g. 55HRC, 60HRC, 65HRC) and applications such as roughing, semi-finishing and finishing. By choosing the right grade, geometry and coating, one end mill carbide cutter can deliver stable performance on multiple materials in your CNC shop.

Flute number is directly related to chip evacuation and rigidity. 2-flute carbide end mill cutter designs are ideal for aluminum and non-ferrous materials where larger chip pockets are needed. 3-flute and 4-flute end mill carbide cutter tools offer higher rigidity and more cutting edges per revolution, which is better for steel, stainless steel and hardened steel. For slotting or roughing you may use fewer flutes; for finishing and side milling, higher flute counts often provide better surface finish.

For distributors and regular customers, we can offer a structured carbide end mill cutter price list based on series, coating and order quantity. For new users, carbide end mill cutter price is usually quoted according to size range, material grade and customization level. Most standard items have low MOQ and we can provide sample pieces for testing before bulk order, helping you verify performance in your own CNC machining conditions.

Yes. We can produce non-standard tools according to your drawings, samples or machining requirements (material, coating, size, tolerance and application). Our engineers will evaluate and provide a quotation and lead time.

For serious buyers and distributors, we can offer free standard samples if in stock. Usually you only need to cover the freight cost. For customized tools, a sample fee may apply, which can be refunded or deducted in bulk orders.

Yes.

Regional or customer protection based on sales targets, avoiding price wars among our partners.

Catalogs, brochures, product photos, technical data sheets, online materials.

For key partners, joint promotion, exhibitions and digital marketing support.

Safety stock for fast-moving items and forecast-based production.

Priority production and regular shipments to reduce stock-out risk.

Clear quality warranty policy, quick response to claims.

Replacement, credit or other solutions after confirmation of issues.

Tool selection and cutting parameter advice.

Problem analysis for different materials and machines.

Online training, documents, and when possible, on-site support for key accounts.

HNCarbide HRC65 4 flute blue nano coated corner radius carbide end mill cutter is designed for high-speed machining of hardened steels, alloy steels and stainless steels up to 65HRC. Manufactured from ultra-fine grain solid carbide end mill cutter substrate and finished on advanced CNC grinding equipment, it provides excellent wear resistance, edge stability and dimensional accuracy at high cutting speeds.

The corner radius geometry on this 4 flute end mill carbide cutter reduces edge chipping, improves tool strength and helps achieve a smooth surface finish on shoulders, pockets and 3D profiles. Blue nano coating enhances heat resistance and anti-adhesion behaviour, keeping cutting edges sharp and chips flowing in continuous or light interrupted cuts. As a professional china cnc carbide end mill cutter supplier, HNCarbide offers this tungsten carbide end mill cutter in a wide range of metric and inch sizes, with optional flute length, shank style and coating for different CNC setups.

Grade HN44F is made from submicron WC powder, some special additives added.

It’s suitable for making drills and end mills, especially for machining steel,Al-based alloys and Ti-basedalloys.

| Grade | Cobalt content % | Grain size | Density g/cm³ | Hardness HRA | Hardness HV30 | MPa Transverse rupture strength | MPa ·m1/2 Fracture toughness MPa ·m1/2 |

|---|---|---|---|---|---|---|---|

| HN44F | 12 | 0.4 | 14.15 | 92.6 | 1,720 | 4,200 | 9.6 |

| Scientific name | Composition | Physical properties | Features | Typical applications |

|---|---|---|---|---|

| Nano-Blue | Blue surface layer: may contain AlCrN (aluminium-chromium nitride) or TiSiN (titanium–silicon nitride); the blue colour comes from nano-structured interference. Nanomultilayer structure: alternating layers such as TiN/AlN (individual layer thickness <50 nm) to increase hardness and thermal stability. | Hardness: 3000–4000 HV (nano-indentation). Friction coefficient: 0.1–0.3 (lower when combined with DLC). Heat resistance: stable up to 1000°C (oxidation starts above 800°C). Adhesion strength: ≥70 N (critical load in scratch test). Surface roughness: Ra <0.05 μm (after polishing). | Blue appearance: achieved by nano-optical thin-film design, and can serve as wear indicator (colour change shows coating loss). Self-lubricating: some Si- or WC-containing nanocoatings can form a silica-based lubricating layer at high temperature. | Recommended workpiece materials High-hardness steels (HRC>50, such as mould steel, bearing steel). High-temperature alloys (nickel-based / titanium alloys, relying on coating heat resistance). Non-ferrous metals (aluminium and copper alloys, requiring low-friction coating to prevent built-up edge). Composites (CFRP, avoiding adverse reactions between coating and fibres). Typical application fields Aerospace: machining turbine-blade dovetails, milling titanium-alloy structural parts. Automotive moulds: high-precision cavity milling, balancing efficiency and surface quality. Medical devices: micro-machining of cobalt-chromium artificial joints. |

Our Corner Radius End Mill drawings clearly show key Corner Radius End Mill dimensions such as diameter, radius, flute length and overall length. This helps you confirm the right Corner Radius End Mill sizes for your CNC setup and machining depth before ordering.

HNCarbide provides carbide end mill cutter tools for a wide range of materials: carbon steel, alloy steel, stainless steel, cast iron, tool steel, hardened steel, aluminum and non-ferrous alloys. Different series are optimized for specific hardness ranges (e.g. 55HRC, 60HRC, 65HRC) and applications such as roughing, semi-finishing and finishing. By choosing the right grade, geometry and coating, one end mill carbide cutter can deliver stable performance on multiple materials in your CNC shop.

Flute number is directly related to chip evacuation and rigidity. 2-flute carbide end mill cutter designs are ideal for aluminum and non-ferrous materials where larger chip pockets are needed. 3-flute and 4-flute end mill carbide cutter tools offer higher rigidity and more cutting edges per revolution, which is better for steel, stainless steel and hardened steel. For slotting or roughing you may use fewer flutes; for finishing and side milling, higher flute counts often provide better surface finish.

For distributors and regular customers, we can offer a structured carbide end mill cutter price list based on series, coating and order quantity. For new users, carbide end mill cutter price is usually quoted according to size range, material grade and customization level. Most standard items have low MOQ and we can provide sample pieces for testing before bulk order, helping you verify performance in your own CNC machining conditions.

Yes. We can produce non-standard tools according to your drawings, samples or machining requirements (material, coating, size, tolerance and application). Our engineers will evaluate and provide a quotation and lead time.

For serious buyers and distributors, we can offer free standard samples if in stock. Usually you only need to cover the freight cost. For customized tools, a sample fee may apply, which can be refunded or deducted in bulk orders.

Yes.

Regional or customer protection based on sales targets, avoiding price wars among our partners.

Catalogs, brochures, product photos, technical data sheets, online materials.

For key partners, joint promotion, exhibitions and digital marketing support.

Safety stock for fast-moving items and forecast-based production.

Priority production and regular shipments to reduce stock-out risk.

Clear quality warranty policy, quick response to claims.

Replacement, credit or other solutions after confirmation of issues.

Tool selection and cutting parameter advice.

Problem analysis for different materials and machines.

Online training, documents, and when possible, on-site support for key accounts.

We Are Commited To Providing High-Quality, Customized solutions At An Affordable price While Also Prioritizing sustainability And ExcellentCustomer Service, These Qualities Make Us A Great choice For Your Carbide End Mill Cutter Needs

We Only Use unground tungsten carbide rods with HlP sintering and100% virgin material. Our grade includes lsO K05 to K40, frommachining carbon steel to aluminium, non-ferrous metals andtitanium or we develop grade for your applications.

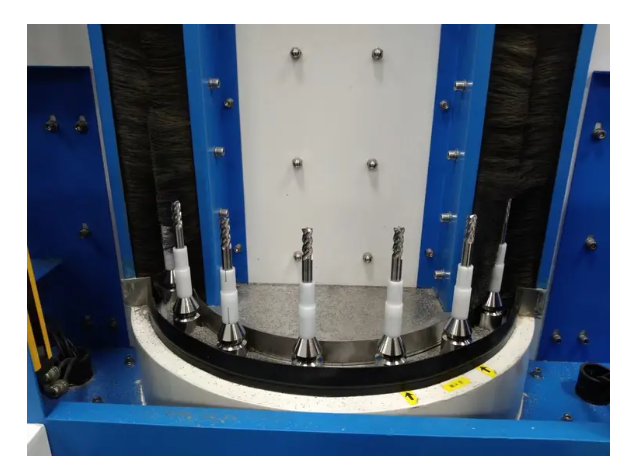

As a HNCarbide customer, you can enjoy five-axis high-precisiongrinding machines from Australia’s ANCA or Germany’s Walter. Themodern workshop with constant temperature and humidity ensuresthe accuracy of each Carbide End Mill Cutter.

Each of your tungsten steel Carbide End Mill Cutter will be sandblasted toeffectively remove burrs and improve the finish.

All HNCarbide’s Carbide End Mill Cutter will be monitored on WALTER HELICHEEK andZOLLER GENlUS 3 to ensure that every dimension is qualified. We arecommitted to controlling the tolerance within 3 UM.

At HNCarbide, every shipment is meticulously packaged to ensure your tools arrive intact.

Each HNCarbide Solid Carbide End Mill Cutter is individually placed in a shock-resistant protective case, labeled with complete specifications, and sealed in moisture-proof packaging material before being boxed.

Large-volume orders are reinforced with double-wall cardboard boxes or wooden crates to maximize safety during international shipping.

We collaborate with reliable logistics partners to ensure goods are delivered quickly and securely to their destination via air freight, sea freight, or express courier.

HNCarbide provides carbide end mill cutter tools for a wide range of materials: carbon steel, alloy steel, stainless steel, cast iron, tool steel, hardened steel, aluminum and non-ferrous alloys. Different series are optimized for specific hardness ranges (e.g. 55HRC, 60HRC, 65HRC) and applications such as roughing, semi-finishing and finishing. By choosing the right grade, geometry and coating, one end mill carbide cutter can deliver stable performance on multiple materials in your CNC shop.

Flute number is directly related to chip evacuation and rigidity. 2-flute carbide end mill cutter designs are ideal for aluminum and non-ferrous materials where larger chip pockets are needed. 3-flute and 4-flute end mill carbide cutter tools offer higher rigidity and more cutting edges per revolution, which is better for steel, stainless steel and hardened steel. For slotting or roughing you may use fewer flutes; for finishing and side milling, higher flute counts often provide better surface finish.

For distributors and regular customers, we can offer a structured carbide end mill cutter price list based on series, coating and order quantity. For new users, carbide end mill cutter price is usually quoted according to size range, material grade and customization level. Most standard items have low MOQ and we can provide sample pieces for testing before bulk order, helping you verify performance in your own CNC machining conditions.

Yes. We can produce non-standard tools according to your drawings, samples or machining requirements (material, coating, size, tolerance and application). Our engineers will evaluate and provide a quotation and lead time.

For serious buyers and distributors, we can offer free standard samples if in stock. Usually you only need to cover the freight cost. For customized tools, a sample fee may apply, which can be refunded or deducted in bulk orders.

Yes.

Regional or customer protection based on sales targets, avoiding price wars among our partners.

Catalogs, brochures, product photos, technical data sheets, online materials.

For key partners, joint promotion, exhibitions and digital marketing support.

Safety stock for fast-moving items and forecast-based production.

Priority production and regular shipments to reduce stock-out risk.

Clear quality warranty policy, quick response to claims.

Replacement, credit or other solutions after confirmation of issues.

Tool selection and cutting parameter advice.

Problem analysis for different materials and machines.

Online training, documents, and when possible, on-site support for key accounts.

In modern CNC workshops, the carbide end mill cutter has become a core tool for achieving high productivity, tight tolerances and excellent surface finish. Compared with traditional HSS tools, solid carbide end mill cutter solutions run at higher speeds, last longer and deliver more consistent results, especially on stainless steel, hardened steel and other difficult materials.

This article explains what a carbide end mill cutter is, the main types you will see in a catalog, how to read a carbide end mill cutter price list, and practical tips for choosing the right tool for your CNC operations.

A carbide end mill cutter is a rotary cutting tool used on milling machines and machining centers to remove material from a workpiece. It is made from tungsten carbide end mill cutter substrate, which offers:

Much higher hardness and wear resistance than HSS

Better performance at high cutting temperatures

More stable dimensional accuracy at high speeds

Because of these properties, carbide end mill cutter tools are widely used in mould and die making, automotive parts, aerospace components and precision engineering. A high-quality end mill carbide cutter allows you to increase spindle speed and feed rate without sacrificing tool life or surface finish.

Flat carbide end mill cutter tools are the most common choice for:

Slotting and side milling

Shoulder milling

General roughing and finishing

They create a flat bottom and sharp edges, which are ideal for pockets and steps.

Ball nose tungsten carbide end mill cutter designs are used for:

3D contouring and free-form surfaces

Mould cavities and die profiles

Finishing complex shapes

The spherical tip allows smooth transitions on curved surfaces and reduces the risk of leaving sharp marks.

Corner radius end mill cutter carbide tools combine a flat bottom with a small radius at the corner. Advantages include:

Less edge chipping in hardened steel

Longer tool life in heavy cutting

Better surface integrity on shoulders and pockets

They are popular for mould inserts and precision components where durability is important.

Start from the material:

Carbon and alloy steels

Stainless steel

Cast iron

Aluminum and non-ferrous alloys

Hardened steels up to 65 HRC

Match the tool grade and coating to the hardness range. A high-performance solid carbide end mill cutter for 60–65 HRC will not be economically ideal for soft steels, and a general-purpose tool may fail quickly in hardened steel.

Flute count has a strong impact on chip evacuation and rigidity:

2 flutes: more chip space, ideal for aluminum and non-ferrous materials

3 flutes: good balance between chip evacuation and strength

4 flutes and above: stronger core, better for steel, stainless and hard materials

Choose flute geometry according to operation: roughing, semi-finishing or finishing.

A good tungsten carbide end mill cutter combines:

Fine-grain carbide substrate (hardness + toughness)

PVD or nano coating (heat resistance + low friction)

Coating helps control heat and chip flow, especially in high-speed or dry machining.

When comparing suppliers, you will usually receive a carbide end mill cutter price list. Don’t only look at the lowest carbide end mill cutter price per piece. Also consider:

Substrate grade and coating type

Tolerance and quality level

Available stock and delivery time

Technical support and customization options

A well-designed china cnc carbide end mill cutter might cost slightly more, but if it offers longer tool life and higher cutting data, your cost per part will be lower.

Many users are familiar with international brands such as niagara cutter carbide end mill solutions. As a professional china cnc carbide end mill cutter manufacturer, HNCarbide focuses on:

Fine-grain solid carbide substrates

Advanced CNC grinding technology

Stable batch-to-batch quality

Flexible customization and reasonable pricing

This allows customers to build a tool library that balances performance and cost, without sacrificing reliability in demanding CNC applications.

To maximize the value of your carbide end mill cutter tools, keep these points in mind:

Use high-quality tool holders to minimize runout

Keep tool overhang as short as possible

Adjust feeds and speeds according to material hardness and tool diameter

Check wear patterns to fine-tune cutting parameters

Use proper coolant or air blast to remove chips from the cutting zone

Even the best solid carbide end mill cutter cannot perform well in poor setup conditions, so machine rigidity and clamping are just as important as tool selection.

WhatsApp us

Before you go, please note that we offer the most up-to-date industry research reports and the most comprehensive product catalogs, so please contact us if you are interested!

Before you go, please note that we offer the most up-to-date industry research reports and the most comprehensive product catalogs, so please contact us if you are interested!