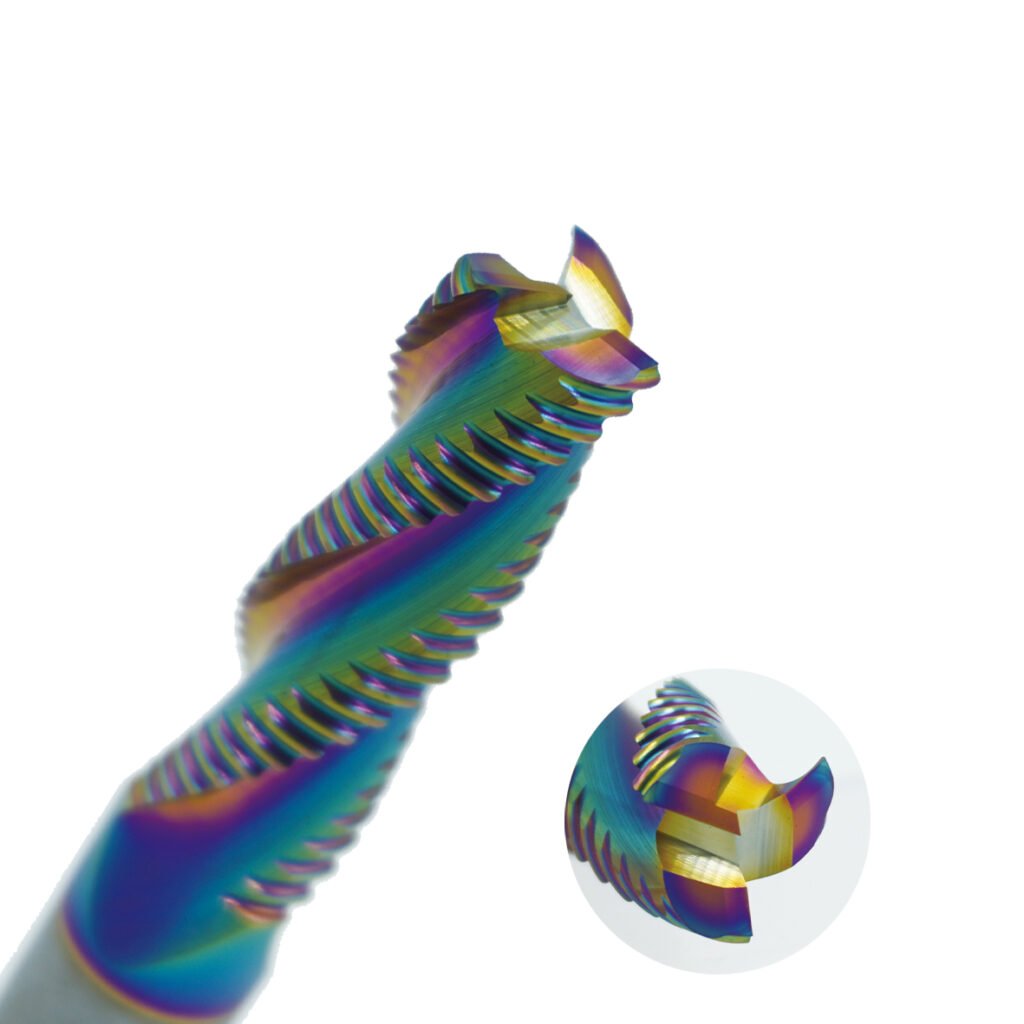

For carbon steel, alloy steel and pre-hardened steels, HNCarbide provides robust cnc roughing solutions that balance aggressive metal removal with stable tool life. Our general-purpose cnc roughing bit for steel features a reinforced core, chip-breaking serrations and optimized flute geometry to reduce cutting forces and vibration under heavy loads. As a dedicated cnc roughing end mill manufacturer, we use wear-resistant solid carbide and high-performance coatings to maintain sharp edges, reliable chip control and consistent performance in your high-efficiency cnc roughing operations.

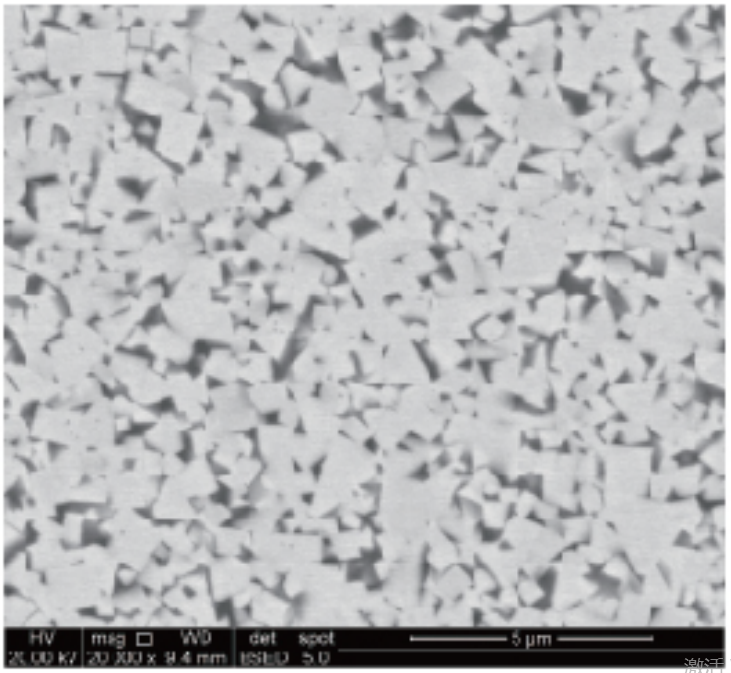

Grade HN40 is made from submicron WC powder, some speclal additlves added to optimize theproperties with good combination of hardness and toughness.

Its suitable for making drills and miling tools for machining stainless steel, tool steel and heat-resistingalloys.

| Grade | Cobalt content % | Grain size | Density g/cm³ | Hardness HRA | Hardness HV30 | MPa Transverse rupture strength | MPa ·m1/2 Fracture toughness MPa ·m1/2 |

|---|---|---|---|---|---|---|---|

| HN40 | 10 | 0.8 | 14.45 | 91.8 | 1,580 | 3,600 | 11.8 |

| Scientific name | Composition | Physical properties | Features | Typical applications |

|---|---|---|---|---|

| TiSiN | Ti (titanium): main element, forms TiN nanocrystalline phase. Si (silicon): usually 6–10%, forms amorphous Si₃N₄ phase, refines grains and increases hardness. N (nitrogen): combines with Ti and Si to form a composite structure. | Colour: TiSiN coatings usually appear bronze or dark grey-bronze; exact colour depends on Si content, deposition process (such as PVD) and thickness (1–4 μm). Hardness: 34–42 GPa (≈3400–4200 HV). Friction coefficient: 0.3–0.6 (against steel). Temperature resistance: 1000–1200°C (oxidation resistance). Coating thickness: 1–5 μm (typically 2–3 μm). Deposition temperature: 200–400°C (suitable for carbide tools). | Ultra-high hardness: amorphous Si₃N₄ phase suppresses dislocation movement, giving much higher hardness than TiN (~23 GPa) and TiAlN (~35 GPa). High-temperature stability: suitable for dry cutting and high-speed machining (e.g. quenched steels HRC 60+). Anti-adhesion: reduces built-up edge when machining aluminium alloys, stainless steels and other sticky materials. | Tool coatings: drills, mills (especially suitable for PCB routers, tool life increased by 2–3 times). High-speed cutting of quenched steels, titanium alloys and high-nickel alloys. Mould strengthening: die-casting moulds and stamping dies, improving wear resistance. Industrial parts: piston rings and other high-temperature wear parts. |

Cnc roughing is the high-efficiency stage of machining where you remove most of the stock before finishing. It uses special roughing end mills with chip-breaking flutes to clear material quickly, reduce cutting forces and protect your machine and spindle.

Yes. Our cnc roughing range covers carbon steel, alloy steel, stainless steel, cast iron and aluminum alloys. We select different flute geometries, helix angles and coatings so each cnc roughing bit matches the material and cutting conditions.

HNCarbide is a dedicated cnc roughing end mill manufacturer with in-house grinding and quality control. We design and produce our own cnc roughing tools and can customize flute length, corner radius, shank type and coating based on customer requirements.

Working directly with a china cnc roughing end mill factory like HNCarbide gives you competitive pricing, stable quality, shorter lead times and fast communication for special designs. You get factory-level engineering support for your cnc roughing applications.

Yes. We can produce non-standard tools according to your drawings, samples or machining requirements (material, coating, size, tolerance and application). Our engineers will evaluate and provide a quotation and lead time.

For serious buyers and distributors, we can offer free standard samples if in stock. Usually you only need to cover the freight cost. For customized tools, a sample fee may apply, which can be refunded or deducted in bulk orders.

Yes.

Regional or customer protection based on sales targets, avoiding price wars among our partners.

Catalogs, brochures, product photos, technical data sheets, online materials.

For key partners, joint promotion, exhibitions and digital marketing support.

Safety stock for fast-moving items and forecast-based production.

Priority production and regular shipments to reduce stock-out risk.

Clear quality warranty policy, quick response to claims.

Replacement, credit or other solutions after confirmation of issues.

Tool selection and cutting parameter advice.

Problem analysis for different materials and machines.

Online training, documents, and when possible, on-site support for key accounts.

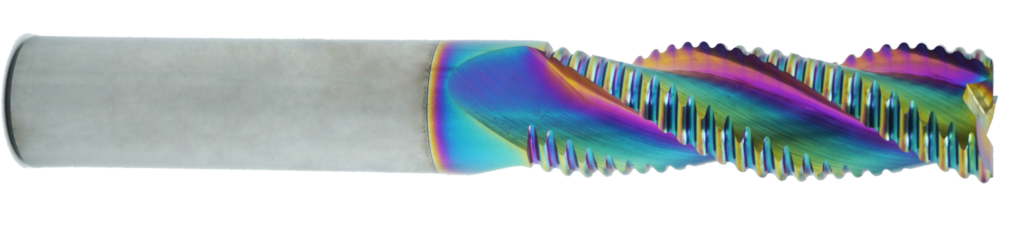

HNCarbide’s 55HRC cnc roughing bit for aluminum is engineered for high-speed, high-volume stock removal on aluminum and non-ferrous alloys. The sharp, polished flute geometry and chip-breaking profile let this cnc roughing bit run at aggressive feeds and speeds while keeping cutting forces low and chips flowing smoothly. A hard 55HRC carbide substrate combined with wear-resistant coating delivers stable performance, clean sidewalls and extended tool life in long production runs. As a professional cnc roughing end mill supplier, we support your aluminum cnc roughing program with consistent quality, customizable dimensions and options for both standard and special geometries.

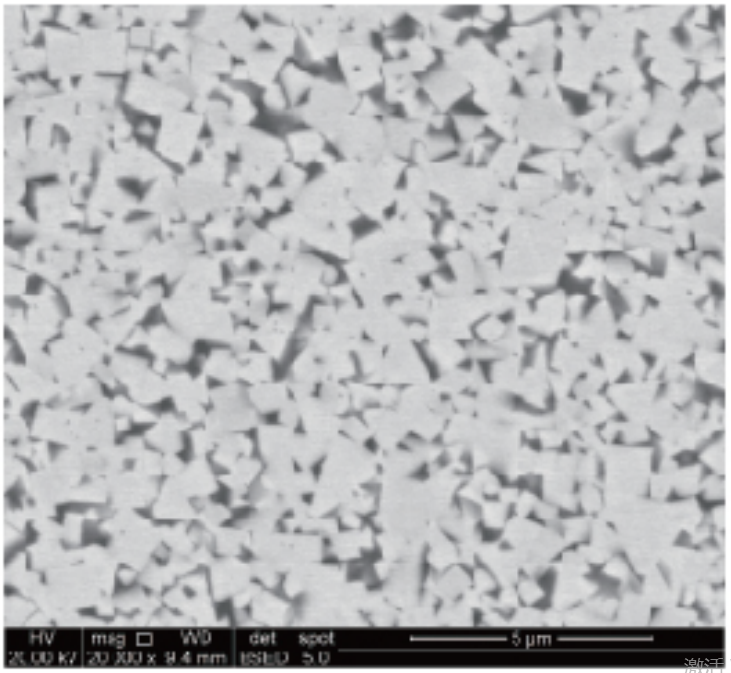

Grade HN40 is made from submicron WC powder, some speclal additlves added to optimize theproperties with good combination of hardness and toughness.

Its suitable for making drills and miling tools for machining stainless steel, tool steel and heat-resistingalloys.

| Grade | Cobalt content % | Grain size | Density g/cm³ | Hardness HRA | Hardness HV30 | MPa Transverse rupture strength | MPa ·m1/2 Fracture toughness MPa ·m1/2 |

|---|---|---|---|---|---|---|---|

| HN40 | 10 | 0.8 | 14.45 | 91.8 | 1,580 | 3,600 | 11.8 |

| Name/Grade | Composition | Physical Properties | Features | Applications |

|---|---|---|---|---|

| Bright | Nano-polishing layer: ultra-smooth surface formed by PVD or CVD, optionally with added Si or B elements. Metallic gloss layer: may contain highly reflective TiN (titanium nitride) or CrN (chromium nitride), giving a bright silver or golden appearance. | Hardness: 2500–3500 HV (nano-indentation). Friction coefficient: 0.1–0.2 (down to 0.05 for DLC composite coatings). Heat resistance: 600–800 °C (DLC may oxidise above 400 °C). Adhesion strength: ≥50 N (scratch test). Surface roughness: Ra < 0.02 µm (after polishing). | Mirror finish: nano-scale multilayer structure reduces surface defects and minimises the need for secondary polishing of the workpiece. Anti-adhesion: oleophobic / hydrophobic design (e.g. fluorine-containing compounds) prevents sticking of soft materials such as aluminium and copper. | Recommended materials: non-ferrous metals (aluminium, copper, magnesium alloys), high-finish steels (mould steels such as P20, NAK80; stainless steels 304, 316), composites (CFRP) and engineering plastics (PEEK, PTFE). Typical applications: precision moulds (mobile-phone housings, optical lens mould inserts), medical devices (artificial joints, dental implants), electronic components (aluminium heat sinks, copper electrodes). |

Cnc roughing is the high-efficiency stage of machining where you remove most of the stock before finishing. It uses special roughing end mills with chip-breaking flutes to clear material quickly, reduce cutting forces and protect your machine and spindle.

Yes. Our cnc roughing range covers carbon steel, alloy steel, stainless steel, cast iron and aluminum alloys. We select different flute geometries, helix angles and coatings so each cnc roughing bit matches the material and cutting conditions.

HNCarbide is a dedicated cnc roughing end mill manufacturer with in-house grinding and quality control. We design and produce our own cnc roughing tools and can customize flute length, corner radius, shank type and coating based on customer requirements.

Working directly with a china cnc roughing end mill factory like HNCarbide gives you competitive pricing, stable quality, shorter lead times and fast communication for special designs. You get factory-level engineering support for your cnc roughing applications.

Yes. We can produce non-standard tools according to your drawings, samples or machining requirements (material, coating, size, tolerance and application). Our engineers will evaluate and provide a quotation and lead time.

For serious buyers and distributors, we can offer free standard samples if in stock. Usually you only need to cover the freight cost. For customized tools, a sample fee may apply, which can be refunded or deducted in bulk orders.

Yes.

Regional or customer protection based on sales targets, avoiding price wars among our partners.

Catalogs, brochures, product photos, technical data sheets, online materials.

For key partners, joint promotion, exhibitions and digital marketing support.

Safety stock for fast-moving items and forecast-based production.

Priority production and regular shipments to reduce stock-out risk.

Clear quality warranty policy, quick response to claims.

Replacement, credit or other solutions after confirmation of issues.

Tool selection and cutting parameter advice.

Problem analysis for different materials and machines.

Online training, documents, and when possible, on-site support for key accounts.

HNCarbide provides cnc roughing tools that fit a wide range of CNC machining tasks, from heavy slotting and side milling to dynamic toolpaths in 3-axis and 5-axis centers. Our high-efficiency cnc roughing bit designs handle carbon steel, alloy steel, stainless steel and cast iron, helping you remove stock quickly while keeping spindle load under control.

Optimized chip-breaking flutes and stable cutting edges make it easier to run a reliable cnc roughing program, improving throughput without sacrificing part accuracy or surface quality.

As a specialized china cnc roughing end mill factory, HNCarbide combines fine-grain carbide substrates, advanced coatings and strict inspection to deliver consistent performance from batch to batch. We operate as both a cnc roughing end mill manufacturer and cnc roughing end mill supplier, offering standard sizes as well as customized diameters, flute lengths and shank types to match your machines and fixtures.

With dependable tool life and repeatable quality, our cnc roughing portfolio helps distributors and end users build a stable, long-term tooling solution for demanding CNC production lines.

We Are Commited To Providing High-Quality, Customized solutions At An Affordable price While Also Prioritizing sustainability And ExcellentCustomer Service, These Qualities Make Us A Great choice For Your Cnc Roughing Product Needs

We Only Use unground tungsten carbide rods with HlP sintering and100% virgin material. Our grade includes lsO K05 to K40, frommachining carbon steel to aluminium, non-ferrous metals andtitanium or we develop grade for your applications.

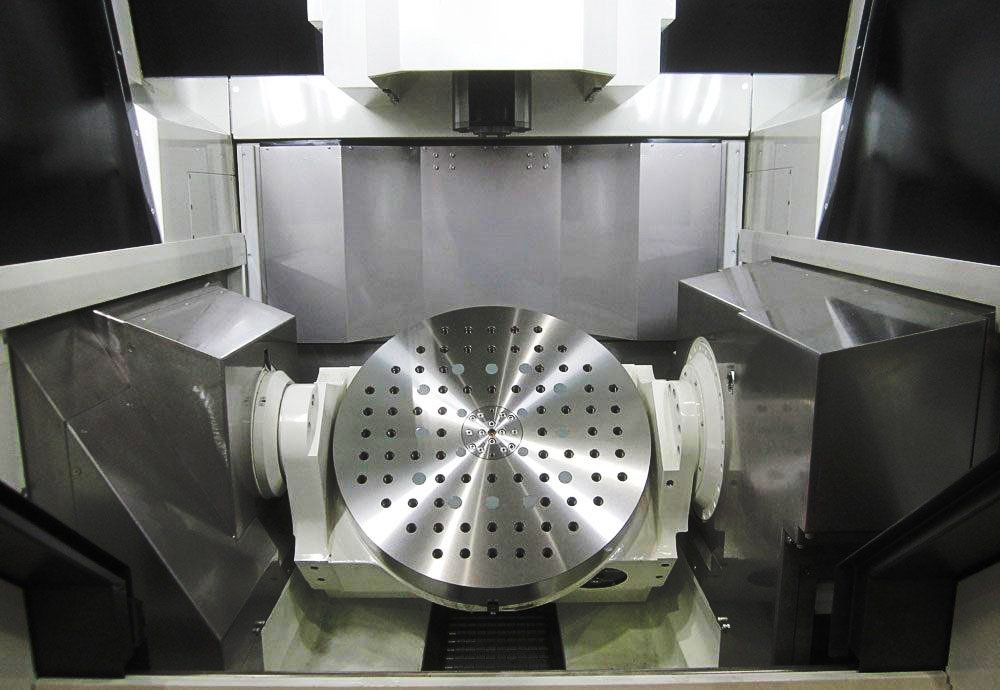

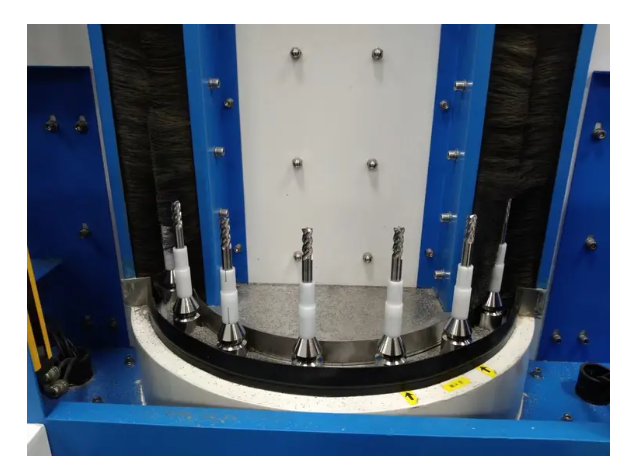

As a HNCarbide customer, you can enjoy five-axis high-precisiongrinding machines from Australia’s ANCA or Germany’s Walter. Themodern workshop with constant temperature and humidity ensuresthe accuracy of each Cnc Roughing Product.

Each of your tungsten Cnc Roughing Product will be sandblasted to effectively remove burrs and improve the finish.

All HNCarbide’s Cnc Roughing Product will be monitored on WALTER HELICHEEK andZOLLER GENlUS 3 to ensure that every dimension is qualified. We arecommitted to controlling the tolerance within 3 UM.

At HNCarbide, every shipment is meticulously packaged to ensure your tools arrive intact.

Each HNCarbide’s Cnc Roughing Product is individually placed in a shock-resistant protective case, labeled with complete specifications, and sealed in moisture-proof packaging material before being boxed.

Large-volume orders are reinforced with double-wall cardboard boxes or wooden crates to maximize safety during international shipping.

We collaborate with reliable logistics partners to ensure goods are delivered quickly and securely to their destination via air freight, sea freight, or express courier.

Cnc roughing is the high-efficiency stage of machining where you remove most of the stock before finishing. It uses special roughing end mills with chip-breaking flutes to clear material quickly, reduce cutting forces and protect your machine and spindle.

Yes. Our cnc roughing range covers carbon steel, alloy steel, stainless steel, cast iron and aluminum alloys. We select different flute geometries, helix angles and coatings so each cnc roughing bit matches the material and cutting conditions.

HNCarbide is a dedicated cnc roughing end mill manufacturer with in-house grinding and quality control. We design and produce our own cnc roughing tools and can customize flute length, corner radius, shank type and coating based on customer requirements.

Working directly with a china cnc roughing end mill factory like HNCarbide gives you competitive pricing, stable quality, shorter lead times and fast communication for special designs. You get factory-level engineering support for your cnc roughing applications.

Yes. We can produce non-standard tools according to your drawings, samples or machining requirements (material, coating, size, tolerance and application). Our engineers will evaluate and provide a quotation and lead time.

For serious buyers and distributors, we can offer free standard samples if in stock. Usually you only need to cover the freight cost. For customized tools, a sample fee may apply, which can be refunded or deducted in bulk orders.

Yes.

Regional or customer protection based on sales targets, avoiding price wars among our partners.

Catalogs, brochures, product photos, technical data sheets, online materials.

For key partners, joint promotion, exhibitions and digital marketing support.

Safety stock for fast-moving items and forecast-based production.

Priority production and regular shipments to reduce stock-out risk.

Clear quality warranty policy, quick response to claims.

Replacement, credit or other solutions after confirmation of issues.

Tool selection and cutting parameter advice.

Problem analysis for different materials and machines.

Online training, documents, and when possible, on-site support for key accounts.

In modern CNC machining, productivity often depends on how efficiently you can remove material at the roughing stage. CNC roughing is where most of the stock is cut away before finishing, and the right tool choice can dramatically reduce cycle time, spindle load and overall cost per part. For shops working with steel, stainless steel, cast iron and aluminum, understanding how to select the correct cnc roughing tools – and the right supplier – is essential.

CNC roughing is the high-efficiency phase of machining in which large amounts of material are removed with relatively heavy depths of cut and stepovers. Instead of focusing on surface finish, the goal is to clear stock quickly while maintaining stable cutting conditions.

Compared with finishing passes, roughing uses special end mills with chip-breaking geometries and strong cores. These tools withstand higher cutting forces, reduce vibration and generate smaller chips that are easier to evacuate from deep pockets or slots.

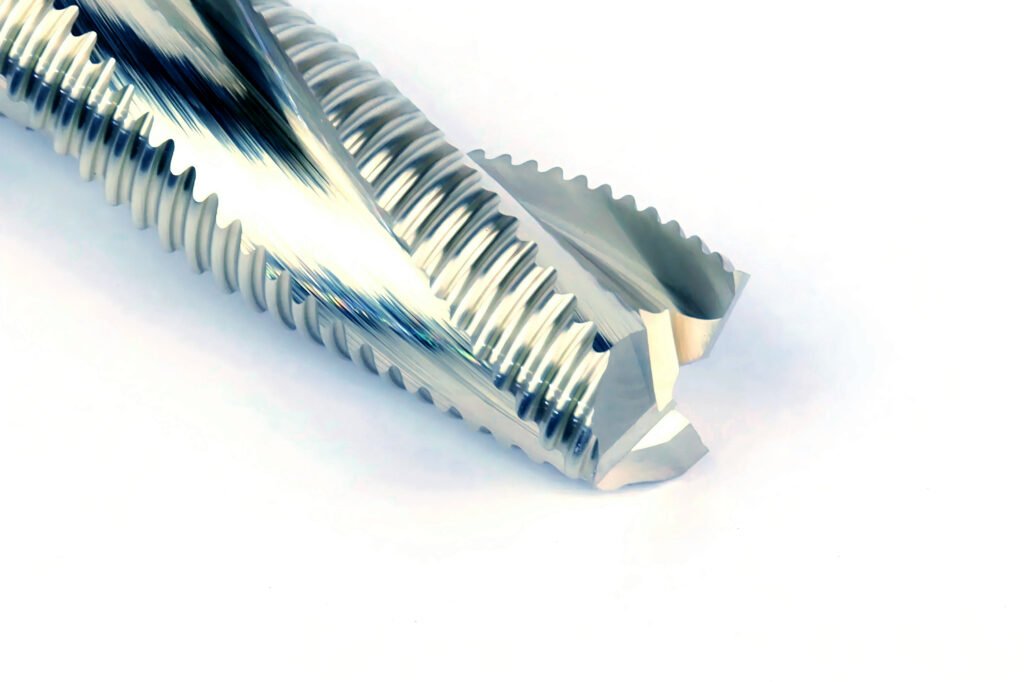

A good cnc roughing bit looks different from a standard smooth-flute end mill. Typical design features include:

Serrated or corn-cob cutting edges that break chips into small segments and reduce cutting pressure.

Reinforced core for better rigidity, which resists bending and chatter at high feed rates.

Optimized flute geometry that pushes chips out of the cutting zone, even in deep cavities.

Coatings such as TiAlN or AlTiN that improve wear resistance and allow higher cutting temperatures in steel and stainless steel.

Together, these elements allow cnc roughing tools to run at aggressive feeds and speeds while keeping spindle load under control and protecting the machine.

Material choice has a major impact on your cnc roughing strategy:

Carbon and alloy steel benefit from solid carbide roughing end mills with tough grades and heat-resistant coatings. These tools handle higher cutting speeds and maintain edge strength under heavy load.

Stainless steel requires sharp, tough cutting edges and carefully controlled chip formation to avoid work hardening and built-up edge. A properly designed cnc roughing bit helps keep chips short and prevents excessive heat.

Cast iron is abrasive, so wear-resistant carbide substrates and coatings are critical to maintain tool life.

Aluminum and non-ferrous alloys need highly polished flutes and sharp cutting edges to avoid sticking and chip packing. Uncoated or special low-friction coatings often perform best for aluminum roughing.

Working with a professional cnc roughing end mill manufacturer makes it easier to match tool geometry and grade to each material type, instead of relying on one generic solution.

Global competition has pushed many buyers to look for reliable partners in China. A reputable china cnc roughing end mill factory can offer:

Competitive cost without sacrificing quality, thanks to efficient production and scale.

Wide product range, including different flute counts, helix angles, corner radii and shank types.

Custom designs, such as special lengths, step tools or unique serration patterns tailored to your parts.

Flexible MOQs and packaging for distributors and brand owners.

The key is to work with china cnc roughing end mill manufacturers that control their own grinding, coating and quality inspection, rather than pure trading companies. This ensures consistent performance from batch to batch and better technical support when you need help optimizing your application.

Even the best tools depend on the correct cnc roughing program. Toolpath strategy, step-over, depth of cut and cutting parameters all influence productivity and tool life.

Common approaches include:

Traditional slotting and side milling, using heavy radial engagement and moderate axial depth.

High-efficiency machining (HEM) / trochoidal paths, which use lighter radial engagement with higher feed rates and deeper axial cuts to keep chip thickness consistent and reduce heat.

Adaptive clearing strategies in CAM software that maintain constant tool load around corners and in pockets.

When setting up a cnc roughing program, start from the manufacturer’s recommended cutting data. Then adjust based on machine rigidity, workholding, coolant delivery and actual chip behavior. Watching spindle load and chip color is a simple way to judge whether the process is running safely or needs fine-tuning.

Choosing the right cnc roughing end mill supplier is as important as selecting the tool itself. A good supplier should provide:

Clear technical support – including recommendations for cutting parameters, toolpath strategies and troubleshooting for chatter or premature wear.

Reliable lead times and inventory planning, so you don’t face downtime waiting for tools.

Quality documentation, such as inspection reports for diameter, runout and coating thickness.

Consistency across batches, ensuring that tools from different orders perform the same on your machines.

Long-term cooperation with a stable supplier reduces your total tooling cost and lowers the risk of unpredictable tool performance.

HNCarbide positions itself as both a cnc roughing end mill manufacturer and a global cnc roughing end mill supplier. As a specialized china cnc roughing end mill factory, we design and produce a complete line of roughing tools for steel, stainless steel, cast iron and aluminum.

Our portfolio includes:

Solid carbide and HSS cnc roughing bit options in multiple flute counts and helix angles.

Coated grades for high-temperature dry or MQL machining, and uncoated/polished designs for non-ferrous alloys.

Standard and customized geometries to fit your existing holders and CAM strategies.

Every tool is ground on advanced CNC equipment and inspected for runout, diameter and edge quality. With repeatable performance and responsive support, we help you build a more efficient cnc roughing process, shorten your roughing cycles and extend tool life across your production lines.

By combining the right roughing strategy, well-designed tools and a dependable supplier, cnc roughing becomes a powerful driver of profitability in metalworking. If you are looking to upgrade your current process or source new tooling from a professional partner in China, exploring cooperation with a dedicated cnc roughing end mill manufacturer like HNCarbide is a strong first step.

WhatsApp us

Before you go, please note that we offer the most up-to-date industry research reports and the most comprehensive product catalogs, so please contact us if you are interested!

Before you go, please note that we offer the most up-to-date industry research reports and the most comprehensive product catalogs, so please contact us if you are interested!