HNCarbide’s 55HRC 2 flute spot drill for aluminum is engineered to give your twist drills a clean, centered start on soft, gummy alloys. The polished flutes and large chip space are optimized for high-speed CNC machining, so this CNC spot drill runs smoothly at elevated spot drill rpm without built-up edge.

Available in popular diameters such as 1/4 spot drill and 3/8 spot drill, this NC spot drill is ground with a stable spot drill angle for both accurate positioning and light chamfering before drilling. The 55HRC substrate and precision edge prep provide a good balance between toughness and hardness, giving you reliable tool life in continuous production.

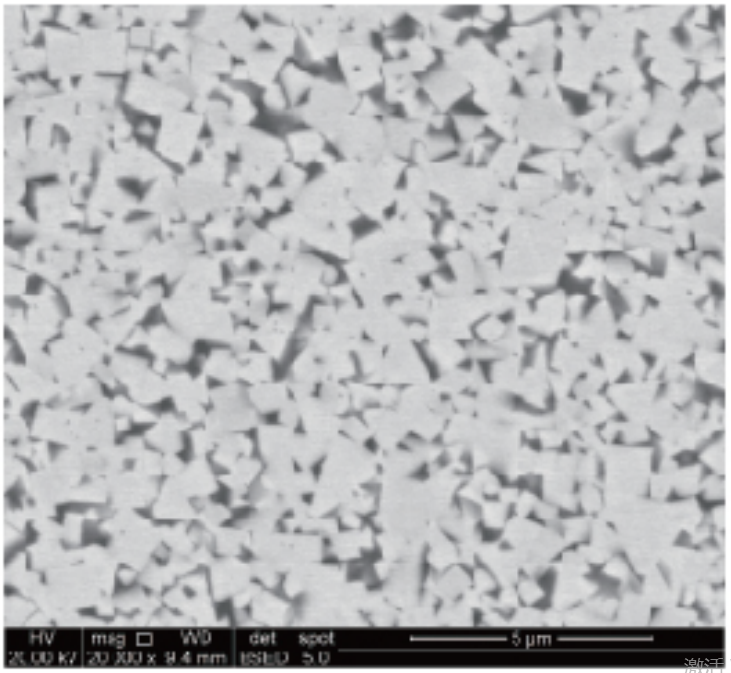

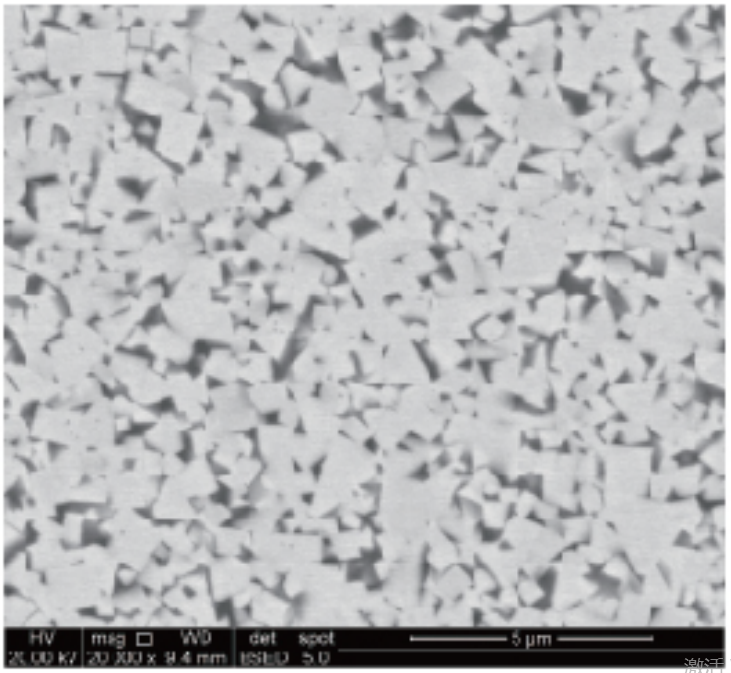

Grade HN40 is made from submicron WC powder, some speclal additlves added to optimize theproperties with good combination of hardness and toughness.

Its suitable for making drills and miling tools for machining stainless steel, tool steel and heat-resistingalloys.

| Grade | Cobalt content % | Grain size | Density g/cm³ | Hardness HRA | Hardness HV30 | MPa Transverse rupture strength | MPa ·m1/2 Fracture toughness MPa ·m1/2 |

|---|---|---|---|---|---|---|---|

| HN40 | 10 | 0.8 | 14.45 | 91.8 | 1,580 | 3,600 | 11.8 |

The spot drill angle should match or be slightly larger than the angle of the following tool. An 82 degree spot drill is common for inch countersinks, while a 90 degree spot drill is often used for general chamfering and through-holes. A 120 degree spot drill or 140 degree spot drill is recommended before many high-performance carbide drills. When comparing 90 vs 120 degree spot drill, 120° usually gives better support for self-centering drills.

Start from the material and tool type. For carbide tools, use higher spot drill speeds and feeds or our carbide spot drill speeds and feeds table; for HSS tools, follow the hss spot drill speeds and feeds chart with lower cutting speeds. Our online spot drill speeds and feeds calculator can give starting values for spot drill rpm and feed per revolution, which you can fine-tune based on your machine and setup.

The diameter is usually equal to or slightly larger than the finished hole chamfer. Common sizes such as 1/8 spot drill, 1/4 spot drill, 3/8 spot drill and 1/2 spot drill cover most applications. You can check our spot drill size chart and detailed spot drill dimensions to match your print and fixture requirements.

Yes. We can produce non-standard tools according to your drawings, samples or machining requirements (material, coating, size, tolerance and application). Our engineers will evaluate and provide a quotation and lead time.

For serious buyers and distributors, we can offer free standard samples if in stock. Usually you only need to cover the freight cost. For customized tools, a sample fee may apply, which can be refunded or deducted in bulk orders.

Yes.

Regional or customer protection based on sales targets, avoiding price wars among our partners.

Catalogs, brochures, product photos, technical data sheets, online materials.

For key partners, joint promotion, exhibitions and digital marketing support.

Safety stock for fast-moving items and forecast-based production.

Priority production and regular shipments to reduce stock-out risk.

Clear quality warranty policy, quick response to claims.

Replacement, credit or other solutions after confirmation of issues.

Tool selection and cutting parameter advice.

Problem analysis for different materials and machines.

Online training, documents, and when possible, on-site support for key accounts.

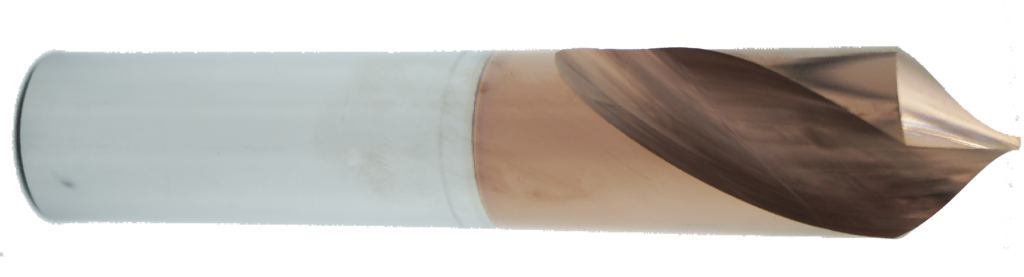

HNCarbide’s 55HRC 4 flute spot drill with bright coating is designed for rigid, vibration-free spotting and chamfering on steel, stainless steel and cast iron, while still performing well on aluminum. Compared with standard spot drill bits, the 4-flute design offers higher stability at elevated spot drill rpm, giving you cleaner entries and more consistent spot drill chamfer around each hole.

Precision CNC grinding ensures a tightly controlled spot drill angle and concentricity, so this NC spot drill / CNC spot drill can be used confidently before high-performance drills or reamers. The bright, polished surface improves chip evacuation and helps reduce built-up edge when you run aggressive spot drill speeds and feeds in production.

Grade HN40 is made from submicron WC powder, some speclal additlves added to optimize theproperties with good combination of hardness and toughness.

Its suitable for making drills and miling tools for machining stainless steel, tool steel and heat-resistingalloys.

| Grade | Cobalt content % | Grain size | Density g/cm³ | Hardness HRA | Hardness HV30 | MPa Transverse rupture strength | MPa ·m1/2 Fracture toughness MPa ·m1/2 |

|---|---|---|---|---|---|---|---|

| HN40 | 10 | 0.8 | 14.45 | 91.8 | 1,580 | 3,600 | 11.8 |

| Scientific name | Composition | Physical properties | Features | Typical applications |

|---|---|---|---|---|

| TiSiN | Ti (titanium): main element, forms TiN nanocrystalline phase. Si (silicon): usually 6–10%, forms amorphous Si₃N₄ phase, refines grains and increases hardness. N (nitrogen): combines with Ti and Si to form a composite structure. | Colour: TiSiN coatings usually appear bronze or dark grey-bronze; exact colour depends on Si content, deposition process (such as PVD) and thickness (1–4 μm). Hardness: 34–42 GPa (≈3400–4200 HV). Friction coefficient: 0.3–0.6 (against steel). Temperature resistance: 1000–1200°C (oxidation resistance). Coating thickness: 1–5 μm (typically 2–3 μm). Deposition temperature: 200–400°C (suitable for carbide tools). | Ultra-high hardness: amorphous Si₃N₄ phase suppresses dislocation movement, giving much higher hardness than TiN (~23 GPa) and TiAlN (~35 GPa). High-temperature stability: suitable for dry cutting and high-speed machining (e.g. quenched steels HRC 60+). Anti-adhesion: reduces built-up edge when machining aluminium alloys, stainless steels and other sticky materials. | Tool coatings: drills, mills (especially suitable for PCB routers, tool life increased by 2–3 times). High-speed cutting of quenched steels, titanium alloys and high-nickel alloys. Mould strengthening: die-casting moulds and stamping dies, improving wear resistance. Industrial parts: piston rings and other high-temperature wear parts. |

The spot drill angle should match or be slightly larger than the angle of the following tool. An 82 degree spot drill is common for inch countersinks, while a 90 degree spot drill is often used for general chamfering and through-holes. A 120 degree spot drill or 140 degree spot drill is recommended before many high-performance carbide drills. When comparing 90 vs 120 degree spot drill, 120° usually gives better support for self-centering drills.

Start from the material and tool type. For carbide tools, use higher spot drill speeds and feeds or our carbide spot drill speeds and feeds table; for HSS tools, follow the hss spot drill speeds and feeds chart with lower cutting speeds. Our online spot drill speeds and feeds calculator can give starting values for spot drill rpm and feed per revolution, which you can fine-tune based on your machine and setup.

The diameter is usually equal to or slightly larger than the finished hole chamfer. Common sizes such as 1/8 spot drill, 1/4 spot drill, 3/8 spot drill and 1/2 spot drill cover most applications. You can check our spot drill size chart and detailed spot drill dimensions to match your print and fixture requirements.

Yes. We can produce non-standard tools according to your drawings, samples or machining requirements (material, coating, size, tolerance and application). Our engineers will evaluate and provide a quotation and lead time.

For serious buyers and distributors, we can offer free standard samples if in stock. Usually you only need to cover the freight cost. For customized tools, a sample fee may apply, which can be refunded or deducted in bulk orders.

Yes.

Regional or customer protection based on sales targets, avoiding price wars among our partners.

Catalogs, brochures, product photos, technical data sheets, online materials.

For key partners, joint promotion, exhibitions and digital marketing support.

Safety stock for fast-moving items and forecast-based production.

Priority production and regular shipments to reduce stock-out risk.

Clear quality warranty policy, quick response to claims.

Replacement, credit or other solutions after confirmation of issues.

Tool selection and cutting parameter advice.

Problem analysis for different materials and machines.

Online training, documents, and when possible, on-site support for key accounts.

HNCarbide spot drill tools are designed for precise hole starting, small chamfers and light countersinks on steel, stainless steel, aluminum and cast iron. Whether you are running an NC spot drill program on a machining center or manual setups in a toolroom, a stable spot prevents drill walking and protects your main drill from chipping on hard or angled surfaces.

Our range includes common angles and diameters so you can match your print requirements: 82 degree spot drill for inch countersinks, 90 degree spot drill for general chamfering and 120 degree spot drill for high-performance drilling. Popular sizes such as 1/8 spot drill, 1/4 spot drill and 1/2 spot drill cover most fixture patterns, while special options are available for deep or tight-access features where a compact CNC spot drill is required.

To simplify programming, HNCarbide provides clear guidelines for spot drill speeds and feeds, spot drill rpm and recommended starting values for different materials. For customers who prefer data-driven setup, we also offer a practical spot drill depth calculator and spot drill speeds and feeds calculator so you can quickly optimize cutting conditions without repeated trial cuts.

Alongside our tools, you can use a concise spot drill size chart, spot drill depth chart and spot drill depth formula to select the right combination of diameter, angle and depth for each operation. Whether you are new to spot drilling or already know exactly what is a spot drill used for in your process, HNCarbide helps you standardize tooling, shorten setup time and improve consistency across all your spotting operations.

We Are Commited To Providing High-Quality, Customized solutions At An Affordable price While Also Prioritizing sustainability And ExcellentCustomer Service, These Qualities Make Us A Great choice For Your Spot Drill Needs

We Only Use unground tungsten carbide rods with HlP sintering and100% virgin material. Our grade includes lsO K05 to K40, frommachining carbon steel to aluminium, non-ferrous metals andtitanium or we develop grade for your applications.

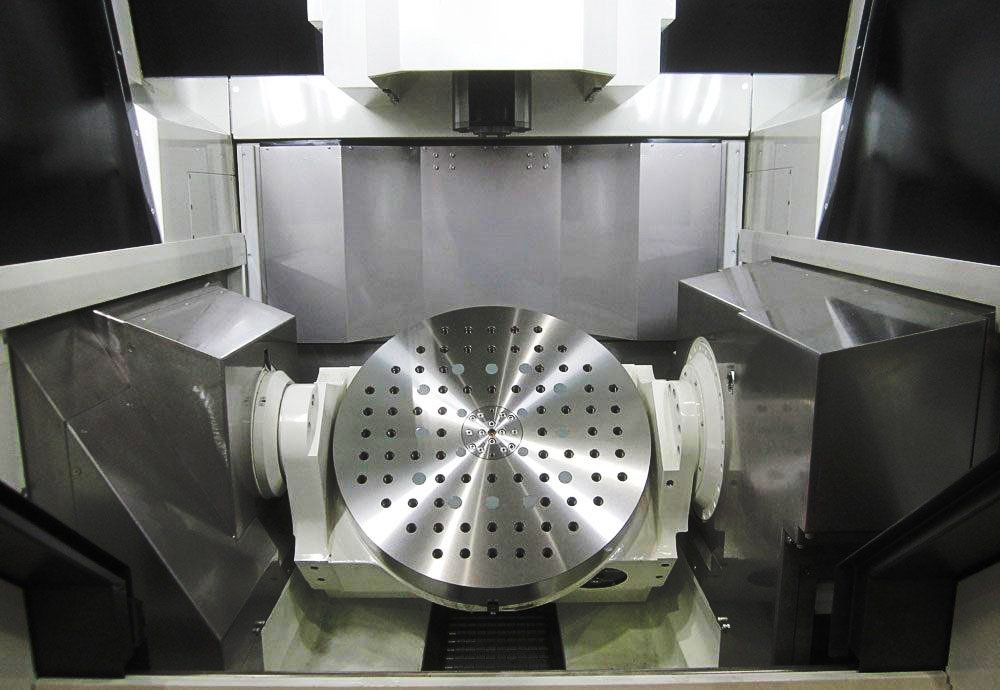

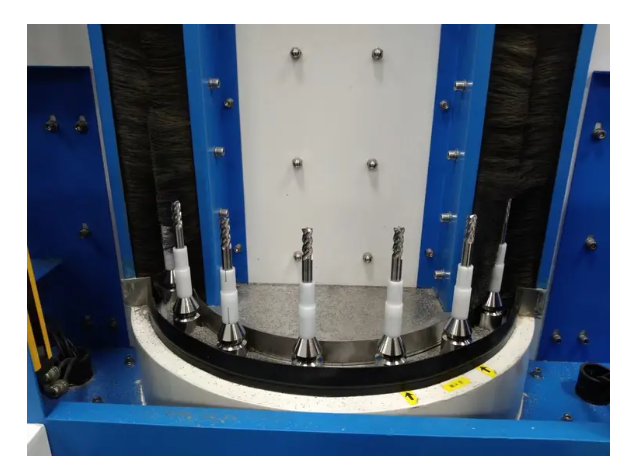

As a HNCarbide customer, you can enjoy five-axis high-precisiongrinding machines from Australia’s ANCA or Germany’s Walter. Themodern workshop with constant temperature and humidity ensuresthe accuracy of each Spot Drill.

Each of your tungsten Spot Drill will be sandblasted to effectively remove burrs and improve the finish.

All HNCarbide’s Spot Drill will be monitored on WALTER HELICHEEK andZOLLER GENlUS 3 to ensure that every dimension is qualified. We arecommitted to controlling the tolerance within 3 UM.

At HNCarbide, every shipment is meticulously packaged to ensure your tools arrive intact.

Each HNCarbide’s Spot Drill is individually placed in a shock-resistant protective case, labeled with complete specifications, and sealed in moisture-proof packaging material before being boxed.

Large-volume orders are reinforced with double-wall cardboard boxes or wooden crates to maximize safety during international shipping.

We collaborate with reliable logistics partners to ensure goods are delivered quickly and securely to their destination via air freight, sea freight, or express courier.

The spot drill angle should match or be slightly larger than the angle of the following tool. An 82 degree spot drill is common for inch countersinks, while a 90 degree spot drill is often used for general chamfering and through-holes. A 120 degree spot drill or 140 degree spot drill is recommended before many high-performance carbide drills. When comparing 90 vs 120 degree spot drill, 120° usually gives better support for self-centering drills.

Start from the material and tool type. For carbide tools, use higher spot drill speeds and feeds or our carbide spot drill speeds and feeds table; for HSS tools, follow the hss spot drill speeds and feeds chart with lower cutting speeds. Our online spot drill speeds and feeds calculator can give starting values for spot drill rpm and feed per revolution, which you can fine-tune based on your machine and setup.

The diameter is usually equal to or slightly larger than the finished hole chamfer. Common sizes such as 1/8 spot drill, 1/4 spot drill, 3/8 spot drill and 1/2 spot drill cover most applications. You can check our spot drill size chart and detailed spot drill dimensions to match your print and fixture requirements.

Yes. We can produce non-standard tools according to your drawings, samples or machining requirements (material, coating, size, tolerance and application). Our engineers will evaluate and provide a quotation and lead time.

For serious buyers and distributors, we can offer free standard samples if in stock. Usually you only need to cover the freight cost. For customized tools, a sample fee may apply, which can be refunded or deducted in bulk orders.

Yes.

Regional or customer protection based on sales targets, avoiding price wars among our partners.

Catalogs, brochures, product photos, technical data sheets, online materials.

For key partners, joint promotion, exhibitions and digital marketing support.

Safety stock for fast-moving items and forecast-based production.

Priority production and regular shipments to reduce stock-out risk.

Clear quality warranty policy, quick response to claims.

Replacement, credit or other solutions after confirmation of issues.

Tool selection and cutting parameter advice.

Problem analysis for different materials and machines.

Online training, documents, and when possible, on-site support for key accounts.

If your twist drills are still “walking” on the surface or chipping at the edges, the problem often starts before the hole is even cut. That is exactly where a spot drill comes in. In this blog we will answer what is a spot drill, what is a spot drill used for, and how to choose the right tool, depth and cutting data for reliable CNC production.

A spot drill is a short, rigid cutting tool used to create a shallow, accurately located feature before the main drilling operation. By producing a small chamfer or conical seat, the spot drill guides the following drill so it enters the part exactly on position and at the correct angle.

Compared with drilling directly, using dedicated spot drill bits offers several benefits:

Reduces drill walking on flat, angled or curved surfaces

Improves hole position and roundness

Protects the main drill point from chipping

Creates a clean entrance chamfer, removing the top burr

For NC and CNC users, an nc spot drill or CNC spot drill is a simple way to stabilize the whole drilling process with very little added cycle time.

One of the key parameters is spot drill angle. The angle of the spot should match or be slightly larger than the point angle of the following drill or countersink.

Common choices include:

82 degree spot drill – popular in inch-based shops because 82° matches many countersinks. Often used when the spot drill also creates the final chamfer for screws.

90 degree spot drill – a very universal choice. It creates a neat chamfer around the hole and works well with many standard twist drills.

120 degree spot drill – often used before high-performance carbide drills that have a 118–140° point angle. A 120° spot provides strong support at the center and helps self-centering drills start smoothly.

If you are not sure which angle to pick, look first at your main drill catalog or print requirement, then choose a spot angle that supports it. HNCarbide can also provide a simple spot drill chart to help standardize this decision.

The next question is diameter. For most applications, the spot drill diameter is equal to or slightly larger than the required chamfer size. Typical workshop choices include 1/8 spot drill, 1/4 spot drill, 3/8 spot drill and 1/2 spot drill, which already cover a wide range of small to medium holes.

To make this easier, many users rely on a spot drill size chart that directly links common screw sizes or hole diameters to the correct spotting tool. HNCarbide can provide such a chart for both metric and inch standards.

Depth is just as important. Too shallow and the main drill will not be guided; too deep and the chamfer may be too large or create a sharp edge. Practical guidelines are:

Depth only needs to be a little deeper than the desired chamfer height

On thin materials, keep spot drill depth minimal to avoid distortion

On hard materials, ensure enough depth to fully engage the drill point

Engineers can use a simple spot drill depth formula based on diameter and angle to calculate this value. For quick work on the shop floor, a spot drill depth chart or digital spot drill depth calculator is even more convenient, especially when you program many different parts.

Because spot drills are short and rigid, they can usually run at higher feed without chatter, but choosing the correct cutting speed remains important. Good starting data depends on tool material and workpiece.

For carbide tools, our carbide spot drill speeds and feeds recommendation uses higher surface speeds and moderate feed per revolution. This is ideal for production machining on steel, stainless steel and cast iron.

For high-speed steel tools, our hss spot drill speeds and feeds tables suggest lower cutting speeds but allow more flexibility on light machines and manual setups.

In practice, you can:

Select the workpiece material and tool type

Use a spot drill speeds and feeds calculator to get starting values

Set your machine spot drill rpm and feedrate based on that suggestion

Adjust slightly after the first part depending on chip color and edge condition

By standardizing spot drill speeds and feeds across your shop, you reduce trial-and-error and make it easier to reuse programs on different machines.

In NC and CNC environments, a spotting operation is usually placed just before drilling in the same tool group. A typical sequence is:

Call the CNC spot drill tool

Rapid to clearance plane

Feed to programmed spot depth using the recommended parameters

Retract to a safe height

Call the main drill and continue with the hole cycle

Because spotting cuts are shallow, the extra time per hole is minimal, but the improvement in reliability is significant. Many shops find that adding a spot drill allows them to increase drilling feed or use longer drills with confidence.

When you have many hole diameters in the same job, you do not always need a different spotting tool for each one. With the help of a spot drill size chart, you can choose a small set of standard spotting diameters that works across most of your parts.

HNCarbide develops a full line of spot drill bits for steel, stainless steel, cast iron and aluminum, with options in both carbide and HSS. Our portfolio covers common diameters and angles as well as special tools for automation and tight-access fixturing.

For customers who are just starting to implement spotting, we provide:

Technical support on what is a spot drill used for in your specific process

Recommendations on angle and diameter selection for typical parts

Parameter tables, spot drill speeds and feeds calculator access and spot drill depth calculator guidelines

Custom designs for non-standard angles, long shanks or integrated chamfers

By combining the right tooling with clear, practical data, HNCarbide helps you turn spot drilling into a simple, repeatable step that improves the quality of every hole you machine.

WhatsApp us

Before you go, please note that we offer the most up-to-date industry research reports and the most comprehensive product catalogs, so please contact us if you are interested!

Before you go, please note that we offer the most up-to-date industry research reports and the most comprehensive product catalogs, so please contact us if you are interested!