How to Optimize Milling of Stainless Steel: Tools, Geometry, and Cutting Strategies

Table of Contents

Milling stainless steel isn’t easy – it takes more than just turning on the machine. This material is tough and can damage your tools quickly if you’re not using the proper setup. That’s why planning is so important.

Selecting the correct one, the correct speeds, angles & coolant, it all comes into play. Making minor adjustments to your cutting tool or method can make a huge difference in performance, cost, and life.

In this post, you’ll discover the best type to use, how to minimise wear & what cutting techniques save time and money. So continue reading to know in detail!

Why Stainless Steel Is Essential in Modern Manufacturing

It is a large part of German manufacturing today and throughout Europe. It’s not just how it looks, although that’s a bonus in consumer items. The primary reason it is so extensively used is that it is a good performer even in harsh conditions.

Businesses such as the automotive, aerospace, medical, & food processing industries depend on it daily. That’s because it is hard, corrosion resistant, and durable. Whether applied to machines, medical instruments, or kitchen appliances, it maintains its strength and shape even when exposed to heat, humidity, or heavy use.

It’s also easy to clean and can handle high temperatures, which makes it ideal for areas where hygiene and safety are important, like in food and pharmaceutical production.

In German industry, where accuracy and quality are crucial, 2 flute end mill help in getting equipment up and running longer and with fewer breakdowns. Less downtime and lower maintenance cost result. As more businesses search for long lasting and environmentally friendly materials, it remains a smart option.

Common Challenges in Milling Stainless Steel

It’s hard and durable, so that’s why it’s used in so many industries. But it’s not always easy. It will stick to your tools & heat rapidly. This makes it difficult to achieve a smooth cut. If not done right, the work can take longer, tools can break, and the final part may not turn out well. Here are some common issues:

● The material often sticks because of heat and pressure.

● A layer can build up, which affects accuracy and finish.

● The metal hardens quickly during cutting, making it harder to machine.

● Cutting puts a lot of force on both the tool and the machine.

● Vibration or noise can affect precision and reduce life.

● Tools can wear out quickly if they’re not right for the job.

● Chips don’t clear well, which can block the path or cause double cutting.

● Too much heat can dull or change the shape of the part.

These issues make end mill for stainless steel tougher to machine than softer metals. That’s why the small things count. With the proper tools and techniques, you can achieve improved results, save time, and reduce expenses.

The Specific Difficulties of Machining Stainless Steel

This brings its own set of problems. These issues can affect life, surface finish, and overall efficiency if not handled properly.

High adhesion and built-up edge

When cutting, one of the most frequent problems is that the material gets stuck on the cutting edge. This occurs because it doesn’t break easily. Rather than leaving behind smooth chips, the metal accumulates on the tool. Eventually, that buildup alters the form of the cutting edge.

The tool stops slicing properly and starts rubbing. This leads to rough finishes on the workpiece and uneven cutting. Built up edges also make the cutting process unstable. You might notice changes in sound, vibration, or part quality during the job. If not handled early, this small issue can quickly damage.

Work hardening and increased cutting forces

Milling stainless steel gets harder the more you cut it. This is known as work hardening. As the tool moves through the metal, the layer just ahead of the cut becomes tougher than it was before. So, the tool has to work harder with every pass. This increases pressure and creates heat in the cutting zone. The heat doesn’t go away easily, which can affect life. If the tool isn’t strong or sharp enough, it may start to rub instead of cut. That puts extra strain on the machine. You might also see more burrs or distortion on the part, which adds time to cleanup and finishing.

Risk of chipping and rapid wear

Milling stainless steel wears faster than many other materials. This is partly due to its strength, but also because the chips are tough to control. They don’t break off in small pieces. Instead, they curl and drag along the tool. This constant contact puts stress on the tool edge. If the geometry isn’t right or the coating isn’t suited for stainless, small chips can form on the edge. Once that happens, cutting becomes inconsistent. A chipped won’t cut cleanly, and it may leave marks or damage the surface. Frequent changes also slow down production and increase cost.

These issues make it less forgiving compared to other metals. It’s not just about using any device. It’s about using the right one with the right setup. If these factors aren’t considered, it often leads to wasted time, broken, and poor results. That’s why understanding the material’s behaviour is key before starting any stainless steel milling job.

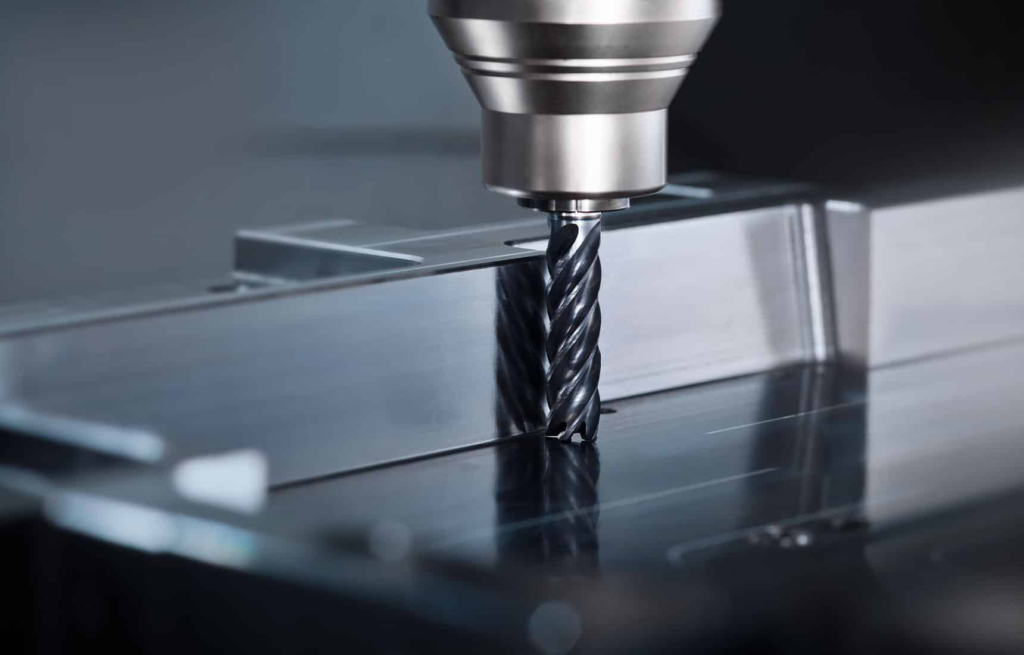

Selecting the Right Carbide Tool Materials

This needs strong tools. Ordinary materials wear out fast or just don’t hold up. That’s why carbide is the better choice. They stay sharp, last longer, and work better under pressure, especially when made with fine grains and special coatings.

Benefits of tungsten carbide over HSS in stainless steel applications:

● Can handle tough metals

● Keeps its shape under heat

● Cuts faster without losing control

● Needs fewer tool changes

● Leaves a cleaner finish on parts

● Less chance of edge damage

● Works well in dry or wet cutting

● Saves time and cost in the long run

Advantages of ultra-fine grain carbide substrates

● Stronger and more stable

● Cuts smoothly, even on hard surfaces

● Holds sharp edges longer

● Less wear on corners and tips

● Good for tight spots and small features

● Handles stress without cracking

● Better chip control

● Great for long production runs

Role of advanced coatings (AlTiN, TiAlN)

Carbide works even better when coated. These coatings are not just a layer. They protect the tool during tough work. AlTiN is great for high speed work. It fights heat and keeps the tool cool. This helps when cutting without much coolant. TiAlN is good at lowering friction. It stops the material from sticking to the tool. That means smoother cuts and longer life.

Both coatings add extra strength. They help the last longer, work cleaner, and reduce the number of times you need to stop and change tools.

Tool Geometry and Design Factors

The shape of your tool affects how well it cuts a flute end mill. A few smart design choices can reduce stress and improve the final part. Let’s look at three features that really help:

Feature | What It Does | Why It Matters |

Large helix angle (up to ~35°) | Helps the chips move out quickly | Reduces cutting pressure and keeps the tool cooler |

Unequal flute spacing | Breaks the cutting pattern | Lowers vibration and makes the cut smoother |

Wave-shaped cutting edges | Breaks chips into smaller pieces | Useful for thin parts that can bend or vibrate |

A larger helix angle means the tool lifts chips out more easily. This makes the cut feel smoother and lowers the pressure. Around 35° is a good balance. It cuts clean but doesn’t weaken.

Unequal flute spacing means the gaps between the cutting edges aren’t the same. This small change helps avoid repeat patterns that cause chatter. It’s a simple way to get a better finish and avoid noise or damage.

Wave shaped edges are great when you’re working with thin walls. These tools cut in a lighter, faster way. The chips break up right away, so there’s less heat and less pushback on the part. That keeps the part steady and helps avoid bending or marks.

Together, these features don’t just protect, they help you get cleaner results, faster and with less trouble.

Best Cutting Strategies

It works best when you choose the right methods. How you cut, how you cool, and how fast you go all make a difference. Here’s a straightforward guide.

Climb Milling vs. Conventional Milling

Aspect | Climb Milling | Conventional Milling |

Cutting direction | Cutter moves with the feed | Cutter moves against the feed |

Surface finish | Cleaner and smoother | Slightly rougher but more stable |

Cutting forces | Lower, less pressure on the tool | Higher, tool pushes harder on material |

Chip removal | Chips flow away easily | Chips can clog or build up |

Tool wear | Less wear, tool stays sharper longer | More wear if not controlled well |

Machine needed | Needs a rigid machine, no backlash | Works on older or less stiff machines |

Best use | Finishing and precise cuts | Rough cuts and tougher jobs |

Risk | Tool can pull workpiece if machine weak | Safer for unstable setups |

Using Coolant and Lubrication

Coolant keeps cool and washes away chips. This stops material from sticking and helps last longer.

● Use water based or oil based coolant

● Spray coolant directly on the cutting zone

● Make sure coolant flow is steady

● Check often to avoid chip buildup

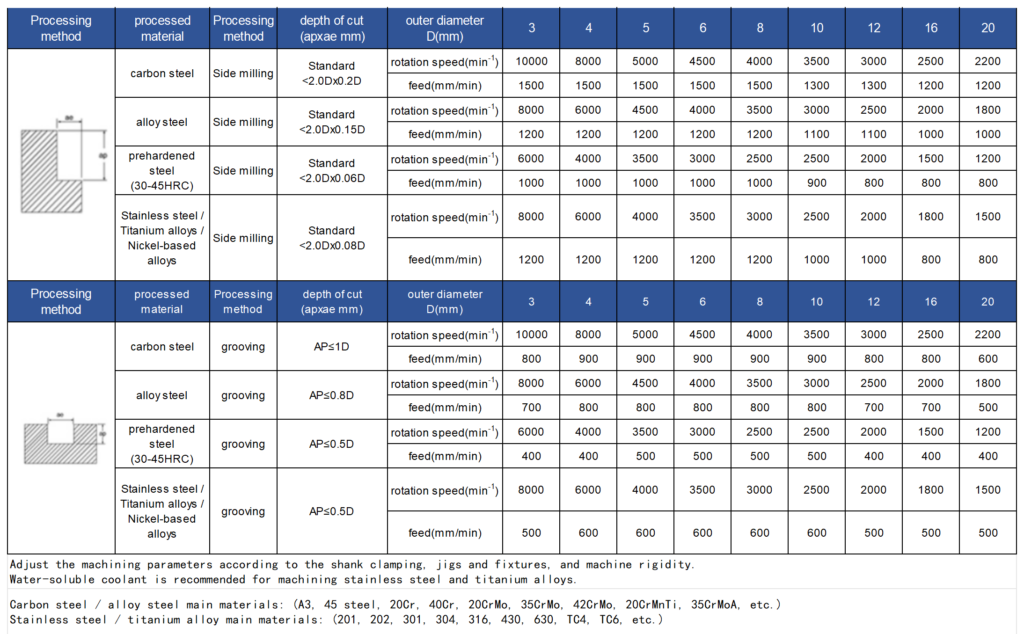

Recommended Speeds and Feeds

Start with these guidelines for carbide tools in milling stainless steel:

● Cutting speed: about 100 to 135 meters per minute

● Feed per tooth: 0.08 to 0.13 millimetres

● Depth of cut: up to two-thirds of the tool’s flute length

Adjust these based on your machine and the part you’re cutting. Using these strategies helps last longer, reduces vibration, and gives a better finish. It makes them smoother and more efficient.

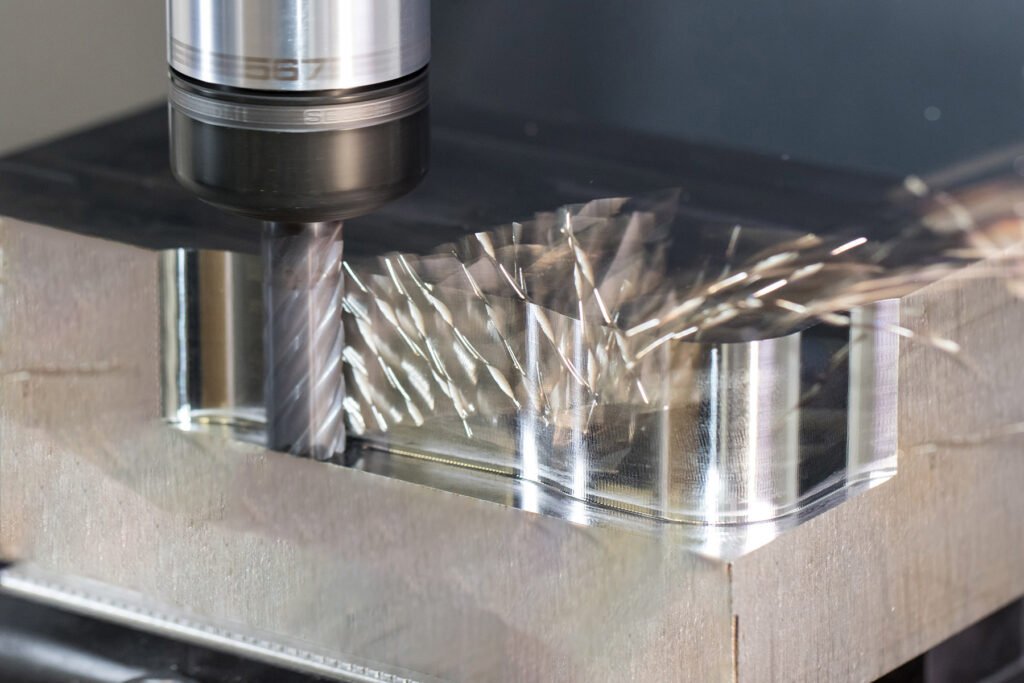

Example: How Specialised Tools Improve Outcomes

High helix carbide end mills have changed how manufacturers mill stainless steel. These have a steep helix angle, usually between 35° and 45°. This design helps push chips away quickly and lowers the force needed to cut through the tough metal.

Case Observation:

● Smoother cutting: The steep helix angle helps chips flow out of the cutting zone easily. This reduces friction and makes the cutting action smoother. As a result, the surface finish on the part is cleaner and requires less polishing afterwards.

● Less vibration: The nominal end mill sizes reduce shaking or chatter during cutting. When the tool stays steady, the cut is more precise. It also lowers the chance of damage, which helps save time and costs.

● Better chip evacuation: The special geometry of these means chips don’t build up or get stuck near the cutting edge. This keeps sharper for longer and prevents problems like built up edges that can ruin a finish.

For instance, a medical supplies company switched regular uncoated end mills with AlTiN coated high helix carbide end mills in machining 316L stainless steel. This resulted in a 40% reduction. Not only did they save money, but they also had an improvement in their overall speed and efficiency in machining.

Many companies report similar results: smoother cuts, less vibration, and faster chip removal. These improvements mean less downtime and higher productivity.

Using special tools like high helix carbide end mill helps in improving tool life and part quality. They prevent wear, maintain the machine for a longer duration, and simplify and lower the cost of milling.

Brand Commitment

We understand that it’s not simple & every detail counts. That’s why we set our focus on producing carbides designed to get the work done. We use the appropriate materials, coatings, and shapes for our tools to provide you with consistent performance.

We collaborate closely with manufacturers to learn what they require and assist them in achieving improved performance with reduced downtime. Whether it’s reducing cut roughness or making last, our aim is to make your work easier.

If you need help with selecting the proper or wish to see how they operate on your equipment, we are here to assist. We can advise what best suits your requirements and even ship samples, so you can test them before making a decision.

When you work with us, you’re not only receiving, you’re receiving assistance you can count on. We pay attention to quality, precision, and assisting you in gaining the optimal results. Contact our team to discuss your project or ask for a sample. We’re here to assist you in improving your milling process.

Conclusion

In order to mill stainless steel correctly, you require good equipment, smart design, and proper cutting techniques. The right shape and coating carbide end mill cutter can smooth out cutting and extend lifespan. Proper coolant, upgrade milling, and balanced speed and feed also make a significant difference.

With the right setup, you’ll see less damage, fewer vibrations, and cleaner results. It also means less time fixing mistakes & more time getting work done.If you’d like help choosing the right carbide tools or want to know more, just reach out to our team. We’re happy to guide you.

DIN Milling Cutters Catalog

Click the button below to view our DIN milling cutters catalog and explore detailed product specifications to make the best choice.