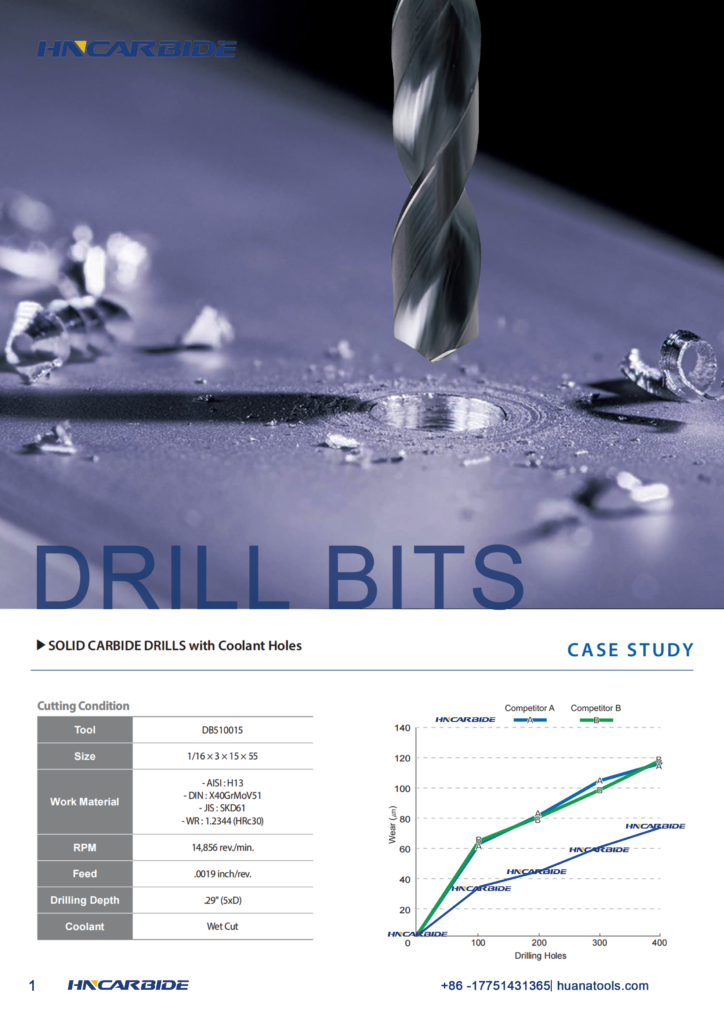

Smart Carbide Drill Bits: Top Brands & Future Tech for Precision Drilling

Carbide drill bits are the silent workhorses in factories, workshops, and construction sites. They slice through the hardest metals like butter, steel, titanium, and hardened alloys. But why do professionals worldwide use carbide rather than ordinary steel drill bits? It all boils down to a secret weapon: tungsten carbide substrate, an extremely tough material that scoffs at heat, resists wear, and lasts 10x longer than standard bits.

Germany, the home of precision engineering behemoths, expects the best. While stalwarts like Guhring and Kennametal command a strong presence in the market with advanced carbide technology, the right bit choice becomes more than just about the brand: Granulation, coatings, and pairing the tool to the job all must be taken into account as well. Knowing the details can save you time, money, and frustration if you need a 3/8 carbide drill bit for steel or a 1/8 carbide drill bit for light work. Let’s dive in.

The Detrimental Impact of Steel Drill Bit Technology

If drill bits: metal-drilling bits were supermen, carbide would be the strongest. Here’s why:

Against Wear: Uncompromisable Hardness

Second only to diamond, tungsten carbide is one of the hardest materials on earth.

Unlike HSS (High-Speed Steel) drill bits, which dull after a few holes, carbide drill bits hold their edge even after hundreds of holes are drilled.

Chills Out Like a Boss in Extreme Heat

High speeds create friction through a drill, generating extreme amounts of heat.

Unlike steel, carbide bits can endure heat, so they won’t soften, lose sharpness, or dull as quickly.

Reliable, Quicker Cuts = Improved Productivity

Carbide bits can operate at 2-3 times HSS speed without failing.

Less vibration = smoother holes, especially in tough metals like stainless steel.

Carbide v/s HSS: Which One Should You Choose for Your Tooling?

Feature | Carbide Drill | Bits HSS Drill Bits |

Lifespan | 10x longer | Wears out faster |

Speed | High-speed | Slower recommended |

Best For | Hard metals, production work | Soft metals, occasional use |

However, carbide is the hands-down choice for German manufacturers who machine hardened steel or operate high-volume production. Next up: the top 10 carbide drill bit brands and what to get in special substrate technology.

Top 10 Carbide Drill Bit Brands and Their Substrate Secrets

1. Kennametal (USA) – KCP25 Carbide for Heavy-Duty Drilling

For a carbide drill bit that gets the job done and keeps on going, look to Kennametal. Their KCP25 carbide substrate resembles the “armor plating” of drill bits, engineered for stainless steel, cast iron, and aerospace alloys. The secret? A durably grained carbide blend that stands up to even the most brutal forces without chipping.

Kennametal is a favorite among German manufacturers for deep-hole drilling in auto parts, where undue heat and pressure would destroy less robust bits. The Thunderbird 3/4 carbide drill bit claims to run at 30% higher speeds than most drill bits, which saves hours of work on large jobs. Kennametal’s Titanium Aluminum Nitride (TiAlN) coating contributes additional heat protection and is ideal for continuously running CNC machines.

Best for: Factories cutting hard metals at high volumes.

2. Ultra-Fine Carbide for the High Precision from Guhring (Germany)

Guhring is a German national treasure. It is known for its superfine grain carbide, which drills clean, precise holes in hard things. Their Gamma carbide technology compresses microscopic tungsten particles more tightly together, resulting in a sharper, longer-lasting edge.

Want to drill through hardened steel with no crack or burr? It takes this in stride with a Guhring’s 1/2 carbide drill bit. (You’ll love this tip if you service any precision tooling.) Their 130° split-point design minimizes walking (skidding) on curved surfaces—great for automotive and toolmaking shops. Coolant channels within the bit keep temperatures cool, even during deep drilling .

Best for: Error-free perfectionists with German engineering expectations.

3. Sandvik Coromant (Sweden) – GC4320 for Intelligent Drilling

Sandvik’s GC4320 carbide mixture is the “Swiss Army knife” for drill bits. It’s harsh and sharp enough to work on stainless steel, titanium, and sticky aluminum.

Their secret? A mid-size carbide compound structure with a bit of flex so it doesn’t snap under pressure. Tip: No pilot hole is required; Sandvik’s CoroDrill 860 series (such as the 5/8 drill bit) features self-centering tips. For mixed-material drilling in German factories, this equals all-in-one.

Best for: Shops working with a range of metals daily.

4. MEGACOAT Super Endurance — Mitsubishi Materials (Japan)

Mitsubishi says MEGACOAT is more than a coating; it is a 5-layer heat and wear shield. They use nano-size grains in their carbide substrate, which gives a smoother cut and extends the bit life up to 40% longer than standard carbide.

Engineered for titanium aircraft parts, their 3/16 carbide drill bit stays sharp for 500+ holes, whereas the other guys fail at 100. The point angle of 140° prevents “grabbing” in gummy metals, which is essential for medical device makers.

Best for: High-value aerospace and medical drilling.

5. Walter Titex (Germany) – 3D Geometry for Speed

Walter Titex marries German engineering with patented flute designs that eject chips more quickly. Their A3D carbide bits (such as the 1/4 carbide drill bit) work 20% faster cutting due to reduced friction.

The substrate secret? A dual-grade carbide—hard at the tip for sharpness and tough at the core to prevent breakage. This is great for large German CNC shops where every second matters.

Best for: Super-fast production lines that drill thousands of holes per day

6. EXO-CARBIDE for Extreme Wear Resistance.

OSG’s EXO-CARBIDE formula is like giving a drill bit an “unbreakable shield.” Their micro-grain carbide has such dense packing that it chuckles in the face of abrasion, even in cast iron or carbon steel.

The star? Their 3/8 carbide drill bit for steel with V-CUT geometry cuts metal like butter, reducing cutting force by 25%. (Labor) Auto-machining their parts for high-mix production (often switching materials) because these bits don’t need constant retuning.

Best for: Job shops that drill various metals daily — without reducing speed.

7. LMT Onsrud (Germany/USA) – “Chipbreaker” Flutes in Carbide

LMT Onsrud only cares about the chips and keeping them managed. They also have wave-shaped, recoil-style flutes that break chips into small bits, helping to prevent clogging in deep drilling (as you’d find in wind turbine shafts).

Check out their 1/2 carbide drill bit with a TiCN coating—it’s a monster on aluminum and composites, which are prevalent in the aerospace world. The 135° separation indicator ensures no walking, even on curved surfaces.

Best for: Drilling sheet metal where chips jamming kill accuracy.

8. Tungaloy (Japan) – Eco-Drill creates Energy Savings

Tungaloy’s Eco-Drill line shows that carbide bits can be tricky and green. Their substrate is made from recycled tungsten, but never fear — it’s as hard as virgin material.

The magic? A low-friction coating that reduces CNC machine power usage by 15%. Their 5/8 drill bit excels in stainless steel pipe fabrication, where long tool life is a close compromise. They love this balance: factories in Germany aim for sustainability.

Best for: green shops that are reaming stainless or alloy steel.

9. Seco Tools (Sweden) — Duratomic® Coating, 2x Life

This is not a layer; Seco’s Duratomic® coating bonds to the substrate, producing a more rigid surface than untreated carbide.

Its 3/4 carbide drill bit makes it through 1,200 holes in titanium (most bits die at 400). * The point thinning design requires 30% less force, which saves machine motors.

Best for: Milling presences cutting exotic metals every day.

10. Universal Carbide for Small Shops Dormer Pramet (Czech Republic)

Dormer Pramet makes a cheaper variant of tungsten carbide bits without significant compromises. Their multi-use substrate works on steel, aluminum, and plastics—perfect for maintenance teams.

The 3/16 carbide drill bit is a bargain: good Life in mild steel, and it has polished flutes that keep chips from welding. It’s not the flashiest , but it’s good enough for German SMEs.

Best for: Tiny shops that want a one-size-fits-all bit.

Drill Bit Product

Catalog

Click the button below to view our DIN milling cutters catalog and explore detailed product specifications to make the best choice.

How to Choose the Right Carbide Drill Bit

When picking the right carbide drill bit is similar to choosing a tool for a job. Here is how to do it in four simple steps:

The material you’re drilling

- Solidity metals (steel, titanium, cast iron):Utilizing fine-grain carbide (of Guhring or Kennametal).

- Softer metals (aluminum, copper): Coarse-grain carbide is better (Sandvik is good).

- Mixed materials: Choose a general-purpose (e.g., Dormer Pramet) bit.

Look at the Grain Size

- Finer grains: sharper edge, better for tool wear in hard metals.

- Coarse grains: tougher, good with soft or gummy metals.

Consider the Coating

- Coating of Gold (TiN): is a general purpose.

- Black (TiAlN) coating:Best for very hot, heavy drilling

- No coating: Less expensive, but also wears more quickly.

Align the Bit Size to Your Task

- Small holes (1/8 carbide drill bit):fine work.

- Big holes (3/4 carbide drill bit):heavy-duty jobs.

Pro Tip: Use a stronger (sub-rate, such as Kennametal’s KCP25) drill bit—if you start breaking one bit, you must go up in the range.

The Future of Carbide Drill Bits

Well, shutdown season is upon us, folks, and we will have to address that, too, because drill bits are more innovative and challenging than ever. Some cool changes will make drilling faster, easier, and more efficient in the next few years. One breakthrough will be hybrid carbide bits that combine regular carbide with ultra-tough materials like diamond or ceramics. When drilling through the toughest metals, for example, these new bits will last far longer than the ones we use today.

A second cool trend is more innovative coatings in drill bits. Self-healing coatings can repair themselves when they suffer minor scratches –think of a coat of paint that can restore its luster automatically when nicked. This means bits will remain sharper and longer without the need for replacement. We’ll also see increasingly common 3D-printed drill bits custom-made for specific machines and jobs. Computers will perfectly shape and design these to function precisely how we need them to.

Another key change is the use of eco-friendly carbide. More companies, like Tungaloy, are adopting recycled tungsten to manufacture their drill bits, which contributes to protecting our planet’s resources. Believe it or not, in the not-too-distant future, drill bits may be outfitted with tiny sensors that notify you when it is time to change the bit because it is losing its edge. This innovative technology will alert workers when they need to swap the bits instead of using guesswork.

That means there will be more accurate, longer-lasting, environmentally friendly drilling in the future. Whether using small 1/8-inch bits or significant 3/4-inch bits, these innovations will make every job easier and more efficient. The drill bits of tomorrow will be your super-genius assistant, making you more efficient and less wasteful.

The Sensor Revolution: Smart Tech Meets Carbide

The next significant advance in drill bits is not about hardness—it’s about brains. New carbide bits outfitted with micro-sensors are popping up in workshops like tiny assistants. These intelligent devices monitor wear live, sending notifications to your phone or CNC machine when they require sharpening or replacement—no more guessing games — just accurate, efficient drilling.

For manufacturers in Germany, this means more uptime and voiceless holes every time. Whether working with a 3/8 carbide drill bit for steel or even a 1/4 carbide drill bit for more delicate parts, sensor-equipped bits prevent you from pushing a questionable tool to its breaking point. No future is just sharp—it’s smart.

Final Thoughts

It matters to decide which carbide tool is right for you—whether you need 1/4 carbide drill bits for precision touch prep on sensitive components or 5/8 drill bits for industrial-scale projects. The right bit doesn’t just get the job done—it does so more efficiently and ensures that your tool lasts longer and every job comes out perfectly every time.

New technologies—from bits with sensors to self-healing coatings—are making drilling operations smarter and cheaper than ever before. Real-time manufacturing data analysis of the production processes allows German manufacturers to obtain an unprecedented level of precision while reducing waste and downtime.

Are you ready to take your toolkit up a notch? High-quality carbide drill bits from top international brands. Everything from 3/8 carbide drill bits for steel to specialized solutions for exotic alloys, we provide the right tools to ensure your operations run smoothly and at high performance. Get in touch today with our experts and find your perfect match.