Milling Cutter Maintenance: A Guide to Solving Frequent Performance Problems

Table of Contents

Milling cutters, including tools such as carbide end mills, end mill bits, and end mill cutters, are essential in industries requiring high precision, such as aerospace, automotive, and mold manufacturing.

Ensuring these tools perform optimally over time is critical for maintaining efficiency and reducing downtime in production lines. Yet, frequent usage can lead to wear and tear, even with top-quality end mills, end mill bits, and carbide end mills.

Why Milling Cutter Maintenance is Important?

Maintaining these tools helps reduce costs and ensures consistent product quality. We will outline the best practices for maintaining your milling cutters, tips for addressing common performance issues, and specific methods to troubleshoot issues in tools like the 4 flute end mill, 2 flute end mill, and various other end mill cutters.

With high-grade tools from reputable end mill manufacturers and end mills suppliers,maintenance becomes more manageable and cost-effective.

4 Common Performance Issues in Milling Cutters

In any machining environment, milling cutters undergo considerable stress. Understanding the frequent performance issues and their causes is essential for maximizing tool life, ensuring high-quality output, and reducing downtime. Below are the primary performance challenges and what they entail.

1. Chipping and Fracturing

Chipping is one of the most common issues affecting end mills and end mill bits, particularly in applications involving high-speed cutting or hard materials. Chipping typically occurs at the edges, but it can also form along the flutes. Causes of chipping include:

- Excessive Cutting Speed: When end mills, such as 4 flute end mills or carbide end mills, operate at high speeds, the cutting edges are subjected to more impact, which can lead to minor cracks or chips.

- Poor Tool Material Match: Using the wrong tool material for specific workpieces, such as harder steels, can cause premature wear. Carbide end mills are designed to withstand hard materials, but improper handling or high impact still leads to edge chipping.

- Vibration and Instability: Machine vibration, caused by worn machine parts or unstable setups, can exacerbate chipping. Even minor vibrations can impact small tools like 1/8 end mills, making them more prone to edge damage.

2. Dull Edges and Tool Wear

Over time, the sharpness of an end mill naturally diminishes, resulting in a dull cutting edge. Dull edges affect the surface finish and increase the force required to cut through the material, leading to additional wear and stress. Reasons for dull edges include:

- High Friction: Constant contact with workpieces creates friction that wears down edges, especially in 2 flute end mills used for aluminum or other non-ferrous metals.

- Inadequate Cooling: Without proper cooling, friction increases significantly, leading to overheating, which softens the tool material and hastens edge dulling.

- Continuous Use on Hard Materials: Harder materials like stainless steel can accelerate edge wear. Carbide end mills and those with specialized coatings last longer but will still dull over time with prolonged use.

3. Tool Breakage

Breakage is a significant issue, particularly in smaller tools like 1/4 end mills or 1 1/2 end mills, where the material thickness is lower. Tool breakage can halt production and lead to additional expenses for replacement. Causes of tool breakage include:

- Improper Feed and Speed: Running an end mill at a high feed rate or speed without considering the material’s hardness can create too much force on the cutting tool, resulting in fractures or complete breakage.

- Unsupported Material: If the workpiece is not secured properly, even minor shifts in material position can stress the tool unevenly, causing it to break.

- Incorrect Tool Type: Using tools not designed for specific materials, such as using standard end mills for hardened steel, can cause instant breakage due to the excessive force required.

4. Poor Surface Finish

The quality of a milling cutter’s surface finish is vital, especially in applications where precision is critical. A rough or inconsistent surface finish indicates a performance issue. Causes of poor surface finish include:

- Dull Cutting Edge: A dull end mill will generate higher friction, producing uneven finishes.

- Excessive Tool Wear: As tools wear down, they struggle to maintain smooth, consistent contact with the material.

- Inaccurate Tool Alignment: Misalignment of the end mill can cause uneven cutting pressure, affecting the final surface quality. This is particularly problematic with larger tools like 1 1/4 end mills.

Understanding these issues and their root causes allows machinists to prevent performance degradation and maintain high-quality machining standards.

Best Practices for Milling Cutter Maintenance

Maintaining your milling cutters through a systematic approach ensures they deliver consistent results while extending their useful life. Here are some best practices that will keep your end mills in optimal condition.

1. Cleaning and De-burring After Each Use

After every machining session, cleaning your end mills and removing any debris or burrs is essential. This helps prevent the build-up of material that could dull the cutting edges or create inconsistencies in future cuts.

- Use a Soft Brush or Compressed Air: Gently clean the tool using a soft brush or compressed air to remove small chips and particles. For carbide end mills, avoid aggressive cleaning methods that could chip or crack the tool.

- Avoid Harsh Chemicals: Mild solvents or specialized tool-cleaning solutions work best, as harsh chemicals may affect tool coatings, leading to quicker wear.

- De-burring: Carefully de-burr any rough areas on the tool to maintain a smooth, sharp cutting edge, especially with custom end mills.

2. Proper Storage to Prevent Tool Damage

Storage conditions are crucial for preventing damage to milling cutters, particularly delicate tools like 1/8 end mills and carbide end mills. Improper storage can lead to accidental chipping and oxidation, reducing tool life.

- Separate Compartments: Store each end mill in individual protective compartments or cases, ensuring they do not contact each other.

- Controlled Environment: Keep tools in a temperature and humidity-controlled environment to prevent corrosion or oxidation, which can weaken the material and reduce tool efficiency.

- Use Protective Tool Cases: For high-end tools from end mill suppliers like Huana Tools, specialized tool cases can protect against external factors and minimize wear.

3. Regular Tool Inspection and Condition Monitoring

Inspecting tools regularly can help identify early signs of wear or damage before they become critical issues. Implement a tool monitoring program that includes checking for:

- Chips and Cracks: Visually inspect tools, especially carbide end mills, which can develop micro-cracks from high-speed machining.

- Edge Integrity: Run your finger along the edge carefully to check for dullness or irregularities. Regular checks ensure high-quality results with each use.

- Diameter and Length Accuracy: Verifying that tools like 1 1/2 end mills or 1 1/4 end mills are still within tolerance prevents accuracy issues in machining.

4. Implementing Tool Rotation and Usage Patterns

Even distribution of tool usage across your tool inventory extends overall tool life. Rotating tools helps prevent overusing any one end mill, reducing wear on individual tools.

- Rotation Schedule: Develop a tool rotation schedule that considers tool type, material hardness, and machining frequency.

- Use Specific Tools for Specific Tasks: Avoid using the same end mill across all materials or operations. For instance, carbide end mills are best suited for hard materials, while other tools may be optimal for softer materials.

- Monitor Usage Time: Tracking usage times for each tool helps in predicting when maintenance or replacement is necessary, ensuring each tool delivers optimal results throughout its lifespan.

5. Sharpening and Re-coating

Sharp tools provide the best results in terms of efficiency and surface finish. While carbide end mills are durable, they benefit from periodic sharpening and re-coating when necessary.

- Professional Sharpening Services: For high-quality tools from end mill manufacturers professional sharpening ensures the tool maintains its precision.

- Use High-Quality Grinding Machines: For in-house sharpening, using precise machines like CNC grinders ensures accurate sharpening angles and edge quality.

- Re-coating for Enhanced Durability: Many end mills, including custom end mills, benefit from re-coating when the original coating begins to wear. Re-coating helps tools withstand high temperatures and reduces friction, extending their usability.

DIN Milling Cutters Catalog

Click the button below to view our DIN milling cutters catalog and explore detailed product specifications to make the best choice.

Solutions to Common Performance Problems in Milling Cutters

Performance issues are common in milling operations, especially when tools like carbide end mills or specialized cutters encounter high-stress conditions. By using practical, targeted solutions, machinists can prevent common problems, extending tool life and maintaining quality. Below are straightforward solutions to the most frequent performance issues encountered in milling.

1. Minimizing Chipping and Fracturing

Chipping and fracturing can occur when high-impact forces or hard materials cause wear on cutting edges, especially in tools like carbide end mills or 4 flute end mills. To minimize chipping:

- Adjust Cutting Speed and Feed Rate: High speeds and feed rates can put excessive strain on the cutting edges, leading to chipping. Start by lowering these settings to reduce impact, especially when working with hard materials.

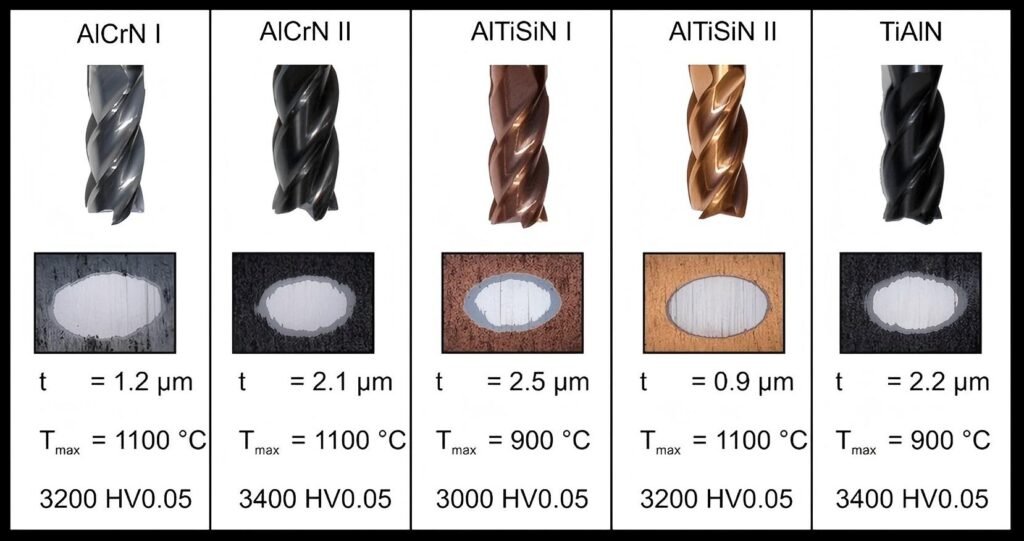

- Choose the Right Tool Coating: Special coatings, such as titanium aluminum(TiAlN), increase a tool’s resistance to wear and heat, helping to prevent chipping. These coatings are beneficial for carbide end mills and other tools that operate at high speeds.

- Use Radial Chip Thinning: Reducing the depth of cut and using a faster feed rate spreads the cutting load more evenly, preventing the tool’s edges from taking on too much force at once. This technique is especially helpful for smaller end mills like 1/4 end mills.

2. Preventing Overheating

Overheating can degrade the quality of end mills by softening edges and reducing hardness. To prevent overheating in tools, follow these guidelines:

- Use Coolant or Lubricant: Coolant is essential to absorb heat during high-speed operations. For small tools like 1/8 end mills, mist cooling is effective, while larger tools may benefit from flood cooling to prevent heat buildup.

- Try Interrupted Cutting: Also known as “peck milling,” this technique allows the tool to cool down briefly between passes, which reduces overall heat. Interrupted cutting is particularly useful for larger end mills like the 1 1/2 end mill, which are more prone to heat buildup.

- Select the Right Tool Geometry: Tools with optimized helix angles and flute shapes allow better airflow and chip removal, which keeps the cutting area cooler. These features are especially effective in high-speed carbide end mills.

3. Reducing Tool Breakage

Tool breakage is costly and disrupts workflow, especially when it affects smaller or high-precision tools. Breakage can usually be prevented by focusing on three key areas:

- Match Feeds and Speeds to Material: Each material requires different settings, so consult the manufacturer’s guidelines to ensure your feeds and speeds are suitable. High feed rates, for example, can easily break thin end mills like the 1/4 end mill.

- Use the Shortest Tool Possible: Shorter tools experience less deflection and vibration, making them sturdier and less prone to breakage. If you’re using a tool like the 1 1/4 end mill, choose the shortest possible length for added stability.

- Check Machine Alignment: Misaligned spindles or tool holders can create uneven forces, leading to tool breakage. Regularly calibrate machines to ensure tools stay aligned, which distributes force evenly across the tool.

Choosing High-Quality Tools for Minimal Maintenance

The quality of your end mills directly impacts the amount of maintenance they require. Tools manufactured by reputable end mill manufacturers,offer durability, precision, and better performance under high-stress applications.

High-quality tools can sustain more intensive workloads, leading to fewer interruptions and repairs. For professionals focused on high-efficiency production, selecting tools from reliable end mill suppliers can reduce overall maintenance needs and improve productivity.

Wrapping Up

Regular maintenance of milling cutters, especially high-precision tools like carbide end mills, end mill bits, and custom end mills, is essential for efficient, uninterrupted production in demanding industries. HNCarbide exemplifies how quality manufacturing and advanced technology, like Rollomatic CNC grinding, result in durable, precise, and reliable end mills. By investing in high-quality tools and adhering to comprehensive maintenance practices, professionals can maintain a competitive edge and ensure the long-term productivity of their equipment.