Europe’s Leading Drill Bit Brands: Top 10 Companies You Should Know

Table of Contents

If you’re wondering which companies lead the way in drill bits across Europe, you’ve come to the right place. As someone who works with power tools daily, I know how important having a quality carbide or solid carbide drill bit is for any project. The big names in Europe like Bosch, Dewalt, and Makita dominate the drill bit manufacturers landscape, especially for tradespeople and professionals.

I will discuss the top 10 European companies that produce the most reliable and innovative drill bits.

What are Drill Bits?

Drill bits are essential cutting tools that create cylindrical holes in materials like wood, metal, plastic, and masonry. They come in many sizes, shapes, and materials – each designed for specific drilling applications and materials. Understanding the different types of drill bits and their compositions is key to selecting the right bit for your project.

Types of Drill Bits

- Twist Drill Bits: The most common type of drill bit features spiraled flutes and pointed tips. The flutes help remove debris, allowing efficient drilling into wood, plastic, and metal. Twist drill bits are versatile and suitable for general home use given their ability to bore holes in various materials.

- Auger Drill Bits: Ideal for woodworking, auger bits are designed to drill deep, wide holes in wood. Their screw-like shape pulls the bit deeper into the material with ease. Auger bits create nice clean holes quickly, making them a favorite for construction applications needing large wooden openings.

- Spade Drill Bits: Featuring a broad, flat blade with a sharp point, spade bits, also called paddle bits, rapidly drill big holes in wood. They are appreciated for their speed but may leave rougher edges compared to other bits. Spade bits are perfect when you need to make various sized openings in wooden crafts or building projects.

- Step Drill Bits: Step bits have multiple diameters along their conical body, allowing drilling holes of various sizes without changing bits. This makes them extremely convenient for creating different sized openings in sheet metal and thin stock. They save time and simplify projects requiring diverse bore widths.

- Unibit Drill Bits: A specialized type of step bit, unibits drill holes of multiple dimensions in a single pass. Unibits efficiently produce openings of different sizes in metal and plastic materials. Their versatility and convenience make unibits a staple in manufacturing and hobby applications.

- Countersink Drill Bits: Countersink bits create angled openings that allow screw heads to sit flush with the material surface. The sloped holes they produce are important for woodworking and cabinetry projects requiring a seamless appearance and smooth feel. Countersink bits are essential fastener installation tools.

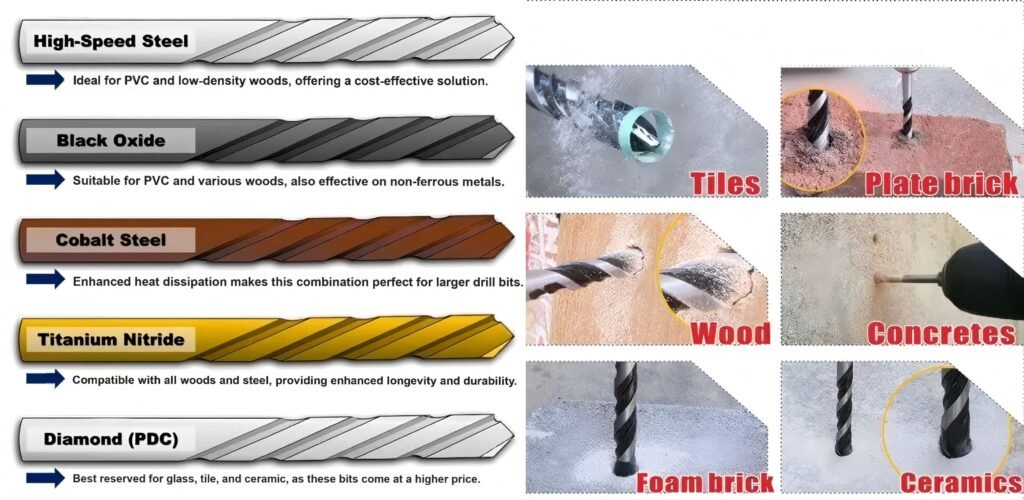

Drill Bit Materials

The composition of drill bits impacts their functionality and best uses. Common materials include:

- High-Speed Steel (HSS): HSS bits resist high temperatures allowing them to maintain sharp cutting edges. HSS is suitable for drilling holes in softwood, plastic, and mild steel since it offers decent hardness at an affordable cost. They are the typical general-purpose bit type for novices.

- Cobalt Drill Bits: Cobalt drill bits contain cobalt steel alloys giving them increased heat tolerance and strength over standard HSS. Their exceptional hardness makes them ideal for drilling stainless steel, other tough metals, and even masonry. Cobalt bits stay sharp much longer than basic versions.

- Titanium Drill Bits: Titanium coatings decrease friction allowing smoother drilling in all kinds of materials from wood to steel alloys. Titanium also improves bit life span making these enhanced drill bits a smart economic choice for those requiring high performance.

- Tungsten Carbide Tipped (TCT): TCT drill bits feature a tungsten carbide tip fused to a steel drill shaft. The carbide provides supreme durability and heat resistance allowing TCT to drill tough masonry, tile, glass, and reinforced composites. TCT bits rank among the longest lasting and most resilient available.

- Solid Carbide Drill Bits: Entirely constructed of carbide, these bits offer unmatched strength capable of drilling the most demanding materials. Solid carbide bits hold up to intense speeds, heat, and wear effects making them the choice for working high-tech alloys and space-age composites. They represent the ultimate in drill bit precision and performance.

- Diamond Drill Bits: When you need to drill really hard substances like stone, glass, or ceramic, diamond is the answer. These bits use tiny diamonds to grind holes with exacting accuracy in the most tenacious building materials and geological samples. Diamond drill bits allow precise boring in the hardest known substances.

Top European Drill Bit Brands

Lets have a loot at Europe’s TOP 10 Drill Bit Brands!

1. Bosch

As a prominent global brand in power tools and accessories since 1886, Bosch offers an extensive selection of top-quality drill bits. Whether you’re a professional or DIYer, Bosch manufactures bits optimized for drilling into concrete, masonry, metal, wood, and other materials.

Bosch specializes in SDS Plus-1 hammer drill bits with 37 options to suit every concrete drilling need. They also produce a wide range of high-speed steel twist bits compatible with standard drills for boring metal. Beyond that, Bosch provides specialty bits for woodworking and construction applications requiring exacting precision.

2. Festool

Festool specializes in premium drill bits and accessories geared towards woodworking and construction applications. Its Centrotec system enables quick bit changes for enhanced efficiency on jobsites. Festool is particularly renowned for its brad point bits ideal for precise, splinter-free drilling in woodworking. It also offers quality HSS metal bits and durable router bits suitable for heavy usage. With a commitment to continuous innovation through ergonomic designs, plus extensive customer resources, Festool ensures its high-performance bits maintain sharpness over time – making them a worthwhile investment for tradesmen.

3. Hilti

With roots dating back to 1941, Hilti has earned distinction as Europe’s top drill bit brand for the construction industry. Its comprehensive drill bit range includes SDS max types for concrete and masonry, specialty bits for rebar and countersinks, plus innovative diamond core bits for large holes. Made with premium carbides and HSS, Hilti bits reliably endure heavy-duty conditions. The company closely controls manufacturing quality while investing in advanced drill bit geometries to drive improved runtimes and lower customer costs. With on-demand technical guidance, Hilti provides constructors unrivaled performance and service.

4. Makita

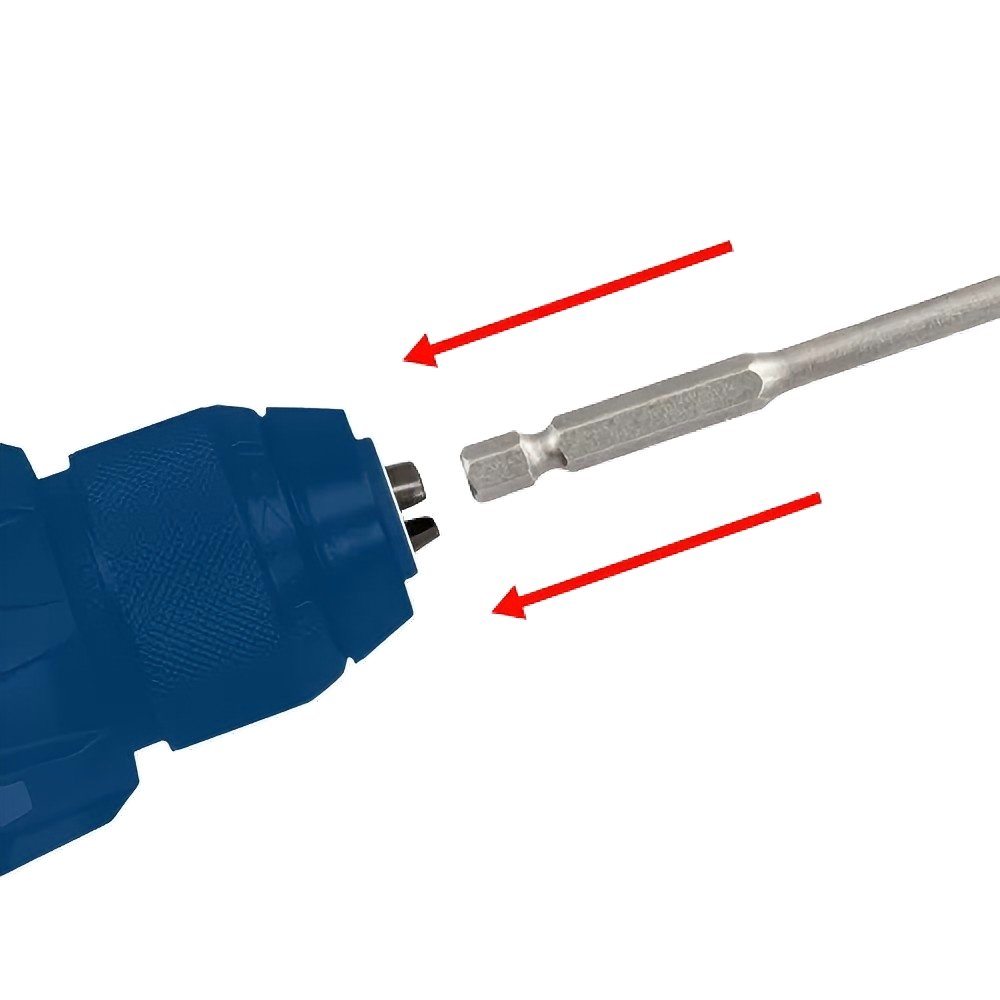

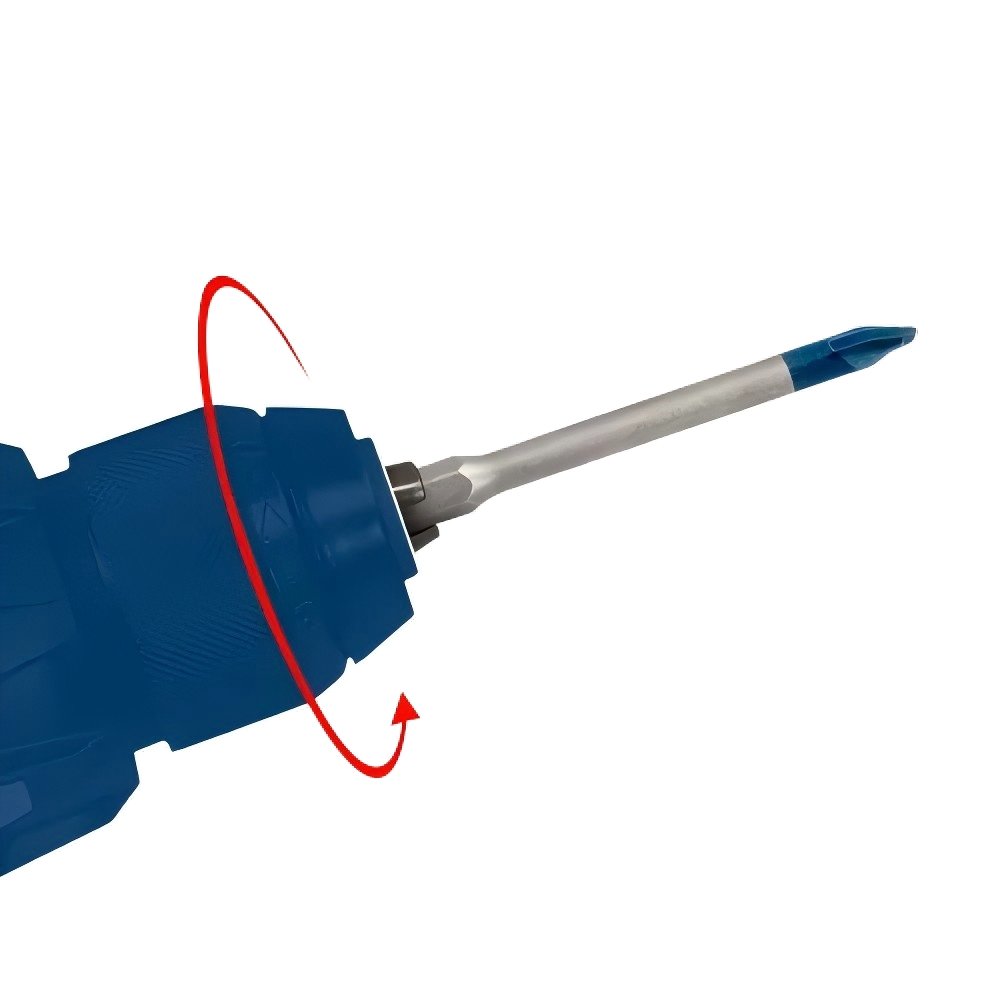

Known for high-quality power tools since 1915, Japanese brand Makita is a leading drill bit supplier in Europe for both professionals and hobbyists. From percussion masonry to multi-purpose, Makita offers optimized bits to bore through brick, wood, ceramic, and metal using the latest materials and designs to enhance efficiency. The company sets itself apart with user-focused innovations like quick-change chucks, dust-lowering extractor bits, and ergonomic tool bodies suited for extended drilling tasks. With its enduring commitment to precision and performance, Makita delivers drill bit durability users can trust.

5. Metabo

With origins dating back to 1924, Metabo ranks among Europe’s foremost drill bit manufacturers for professional users. Its comprehensive selection includes HSS, titanium, masonry, and SDS drill bits optimized for demanding metalworking, concrete, and construction applications. By employing tight tolerances and quality German engineering, Metabo ensures its drill bits deliver reliable precision when drilling into the toughest materials. With a focus on customer support through detailed user guides and technical assistance, Metabo equips tradesmen to maximize the performance of their tools.

6. Wera

Renowned for its high-quality drill bits and innovative tool designs, Germany’s Wera serves both expert tradesmen and hobbyists. Wera manufactures durable, versatile drill bits featuring advanced geometries and coatings ideal for drilling wood, metal, and masonry. The brand concentrates on user-friendly enhancements as well, like quick-change bits and ergonomic shaping to boost productivity. With its twist, screwdriver, and specialty bits, Wera provides professionals trusted drilling solutions flexible enough for varying demands.

7. Screwfix

As a prominent UK retailer, Screwfix supplies drill bits to suit diverse consumer and trade requirements. Their selection consists of HSS twist bits, masonry bits, spade bits, and countersinks manufactured to drill an array of materials without frequently replacing tools. Screwfix ensures its affordable drill bits fit most common power drills and hammer drills for versatility across applications. Whether an electrician needing Diamond drill bits or a DIYer using auger bits, Screwfix accommodates most drilling tasks.

8. CMT Orange Tools

Renowned for precision woodworking tools, CMT Orange Tools produces heavy-duty drill bits geared towards professionals and hobbyists alike. It offers durable dowel drill bits made from super-strength steel for accurate boring, along with Forstner bits that excel at creating clean, flat-bottomed holes ideal for cabinetry. CMT Orange Tools also provides specialty bits designed to cover unique drilling needs for woodworking projects.

9. Fischer

The German company Fischer has earned distinction for high-quality drill bits focused on the construction and DIY realms. Fischer manufactures robust masonry bits tailored towards efficiently drilling concrete, brick, and stone. To enable secure installations, Fischer pairs their drill offerings with screw and anchor systems designed for various materials. Beyond standard bits, Fischer offers solutions for drilling specialty materials like reinforced steel.

10. Bosch Rexroth

A division of the reputable Bosch Group, Bosch Rexroth directs its innovative German engineering prowess toward manufacturing specialized, heavy-duty drill bits. It serves primarily industrial sectors through precision drill bits that meet specific requirements from metalworking, construction, and other fields. Bosch Rexroth constructs these advanced bits using unique geometries and high-performance metals to ensure durability across demanding drilling applications. This allows the company to provide targeted solutions with the reliability expected from Bosch.

Drill Bit Applications

Drill bits serve an integral role across industries by creating necessary holes and openings in materials. The specific drill bit utilized depends on factors such as the material, hole size, precision level, production speed, and operating conditions. By selecting bits based on application requirements, optimal drilling productivity and efficiency can be achieved.

Construction Industry Drill Bits

In construction, durable carbide drill bits are heavily favored for drilling holes in:

- Concrete:To secure structural framework and enable anchoring.

- Masonry drill bitsbore through brick, block, and stone when erecting walls.

- Auger bits open deep holes in wood for tasks like framing and pole building.

- Cobalt bits drill metal framing made of steel or aluminum. Tile and glass drill bits create openings to install fixtures and mount accessories.

- Drywall drill bitsfasten paneling securely.

Carbide’s extreme hardness provides the strength and longevity necessary for heavy-duty drilling into robust materials on job sites.

Manufacturing Industry Drill Bits

Manufacturing settings demand precision when drilling materials like:

- Metals:Hole boring in steel, aluminum, copper etc. for machinery and parts fabrication.

- Alloys: Aerospace and automotive applications utilizing superior strength alloys.

- Plastics: Lightweight plastic components across vast consumer products.

- Composites: Cutting lightweight, durable composite materials used in aerospace.

Solid carbide or carbide-tipped drill bits maintain consistent accuracy when drilling at high speeds necessary for mass production.

Mining Industry Drill Bits

Mining operations employ durable bits when boring into:

Coal for energy production. Metals like copper, iron, gold etc. to extract ore deposits. Minerals and precious gemstones locked within rock encasing.

Mining drill bits contend with highly abrasive conditions. Thus, tungsten carbide bits known for hardness and thermal resistance are commonly utilized.

Oil and Gas Industry Drill Bits

Extracting fossil fuels requires customized bits that can drill:

Rock and shale formations harboring oil reserves. Sandstone that often contains valuable crude oil deposits. Hydrocarbon-rich limestone stores that feed pipelines.

Wellbore bits drill main access holes while wellhole bits construct offshoot bores. Oil field drill bits feature cutting geometries designed to penetrate oil-laden geologic strata. These specialty drill bits efficiently access subterranean fuel stores cost-effectively.

Global Drill Bit Industry Growth Projections

The global drill bit market appears primed for substantial growth in the coming years, fueled by surging demand across key sectors utilizing drilling equipment. Analysts project the total market to expand at a compound annual growth rate (CAGR) of 5.8% from 2025-2030 as industries ramp up production and construction activity intensifies.

Several factors expected to spur drill bit market growth through 2030:

Construction Sector Expansions:

Robust construction sector growth will likely boost drill bit sales, especially in developing regions urbanizing rapidly. Drill bits help erect buildings, bore infrastructure tunnels, and enable various construction drilling tasks. With the value of global construction output estimated to rise $8 trillion by 2030, drill bit manufacturers stand to benefit.

Advancing Manufacturing Activities

Higher production volumes across manufacturing verticals often necessitate new machinery and tooling outfitted with specialized drill bits boring key components. As manufacturing activity accelerates worldwide, demand for durable drill bits enabling mass-production will heighten.

Rising Mineral and Commodity Prices

Pricier minerals and raw commodities incentivize mining companies to expand operations, a trend projected to escalate drill bit demand. By 2030, the global mining sector’s capital expenditure is forecasted to hit $70 billion as miners acquire equipment, replacement parts, and drill bits facilitating more aggressive extraction efforts.

Surging Oil & Gas Exploration

Despite transitions towards renewable energy, fossil fuels will remain integral to global energy needs in the near-term. Therefore, heightened oil and gas drilling activities through 2030 will spur demand for technically-advanced drill bits reaching remote deposits as companies invest heavily in exploration.

European Drill Bit Market Outlook

Drill bit manufacturers enjoy strong long-term prospects in Europe as well, underpinned by steady economic progress across countries like Germany, France, Italy. According to data projections:

2025 European Drill Bit Market: $3.5 Billion Revenue

By 2025, Europe’s drill bit market is poised to reach roughly $3.5 billion in size. Germany boasts the largest share of this robust market while minimal untapped potential and drilling sensitivity curb faster growth in Western Europe. However central Europe presents drill bit producers meaningful opportunities given its lower market maturity.

2030 European Drill Bit Market: $4.5 Billion Revenue

Europe’s drill bit marketplace revenue expands further to an estimated $4.5 billion by 2030. This 28% revenue growth over 5 years results from an anticipated uptick in regional construction initiatives, manufacturing production, and specialty bit demand from industries like aerospace where Europe retains a competitive edge. If European economic stability persists amidst global volatility, drill bit manufacturers can expect amplified sales.

Leading European Drill Bit Brands

We’ve discussed the prominent European drill bit companies like Bosch, Festool, Hilti, and Makita serving industries through advanced offerings. These leading brands apply decades of expertise to pioneer innovations meeting precise application requirements. As demand grows for durable, specialized bits, top manufacturers like Bosch, Metabo, and Wera appear set to elevate performance across materials.

Buoyed by a foundation of quality German engineering, the European drill bit sphere seems primed for ongoing expansion. By merging precision with durability, prominent regional producers will uphold Europe’s esteemed reputation in global drill bit technology.